PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

Typical Technical Parameters Specification Details Product Type Electronic Trip Unit Test Device Name Ekip TT accessory Intended Use Trip test for ABB electronic trip units on breakers Compatible Breakers Moulded‑case and LV breakers with Ekip trip units (e.g., Tmax XT2/XT4, Emax²) Key Functions Trip test, LED test, latest trip status indication Power Supply Self‑contained (battery powered) to energize the trip unit Connection Interface Front test port on the Ekip trip unit Form Factor Handheld / portable test unit Status Indication LEDs to show test status and recent trip cause Typical Use Commissioning, diagnostics, maintenance Weight / Size Compact, pocket‑sized accessory

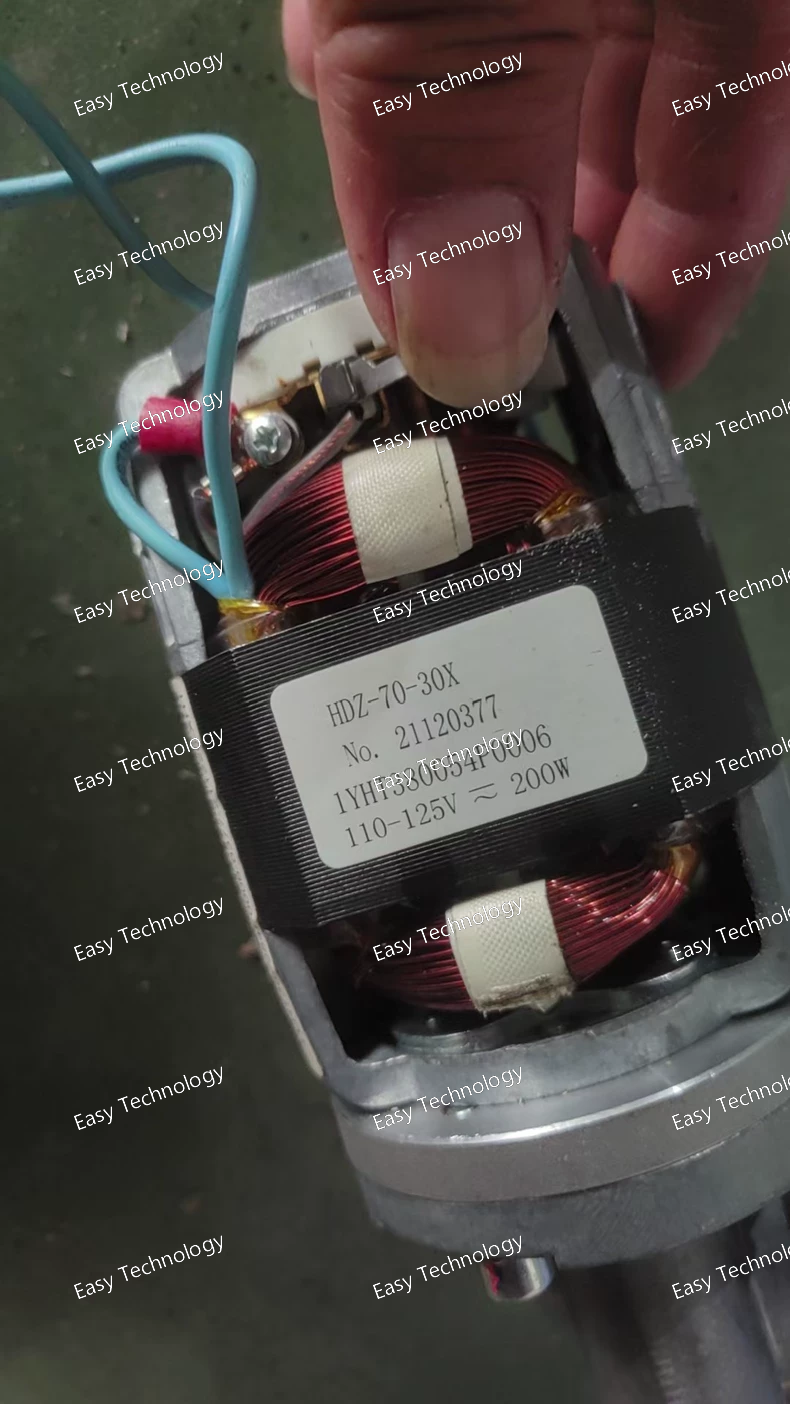

Technical Parameters Specification Typical Details Product Type Spring‑charge / Storage Motor for Breaker Mechanism Model Family HDZ‑70‑30x Brand ABB Function Charges the mechanical spring in medium‑voltage circuit breaker operating mechanism Control / Supply Voltage 110–240 V AC/DC (commonly chosen per variant) Drive Power ~180–200 W (motor power for charging spring) Operating Speed Fast torque for charging internal spring mechanism Mounting Mounted on breaker frame or actuator assembly Environment Low‑voltage control compartment within breaker gear Typical Use Medium‑voltage vacuum breaker mechanism actuation Applications Spring charging for breaker open/close operation in switchgear

Technical Parameters Specification Details Product Type Ethernet Communication Interface Module Model / Part Number PNQ22‑FBP.0 (1SAJ261000R0100) Brand ABB Primary Function PROFINET IO interface for Universal Motor Controllers Compatible Devices Up to 4 x UMC100.3 motor controllers Network Protocol PROFINET IO industrial Ethernet Ethernet Ports Dual RJ45 for network connection and daisy‑chain/switch Control Interface Type Industrial Ethernet with integrated switch Supply Voltage 24 V DC control supply Mounting DIN‑rail (IEC standard TH35) Degree of Protection IP20 (enclosure) Operating Temperature 0 °C to +60 °C Storage Temp. ‑25 °C to +70 °C Pollution Degree 3 Power Consumption ~3.5 W Dimensions (W×H×D) ~45 mm × 90 mm × 96 mm Weight ~0.172 kg Indicators LED status for network and communication activity Recommended Mounting Rail TH35‑15 / TH35‑7.5 Standards IEC/EN and industrial Ethernet standards

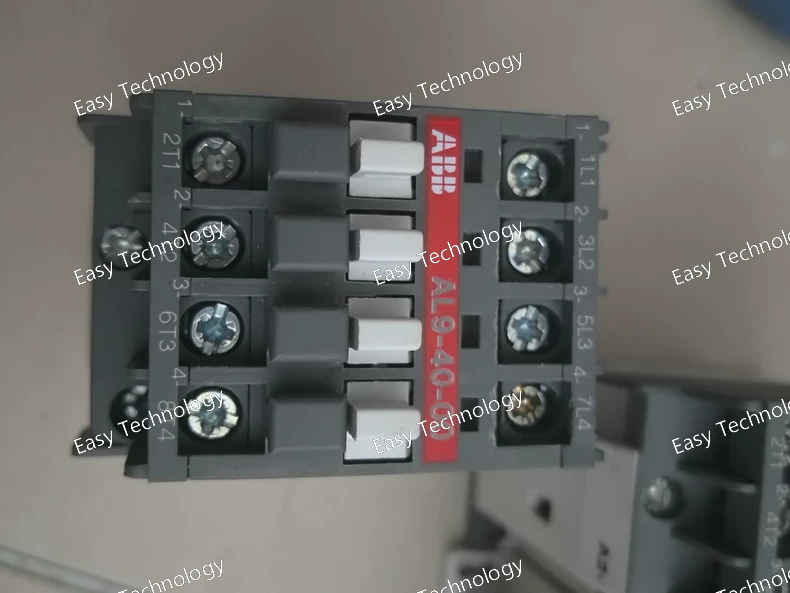

Technical Parameters Specification Details Product Type AC Magnetic Contactor Series / Model AL9‑40‑00 (4‑pole) Number of Poles 4 Normally Open (4NO) Rated Operational Voltage (AC) Up to 690 V AC Rated Operational Current (AC‑3, motor load) 9 A Rated Operational Current (AC‑1, resistive load) 25–40 A Coil / Control Voltage Options Multiple, e.g., 12 V DC, 24 V DC, 110 V DC, 220 V DC, 230–240 V AC/DC Rated Insulation Voltage 1000 V AC Rated Impulse Withstand Voltage 8 kV Duty Type AC‑1 / AC‑3 (IEC 60947‑4‑1) Mechanical Durability >10 million operations Electrical Durability >1 million operations Terminals Screw‑type connections Auxiliary Contacts None (main poles only) Mounting Panel / DIN rail or screw mount Operating Temperature ‑25 °C to +60 °C Protection Rating IP20 Typical Applications Motor starters, lighting systems, general power switching Standards Compliance IEC 60947 series

Parameters Specification Details (Typical) Product Type Loop Switch / Continuity Module Function Maintains network loop continuity in modular controller systems Communication Interfaces Multiple RJ45 network/BUS ports (Ethernet & internal BUS) Mounting DIN‑rail or panel mount in switchgear Operation Auto‑bypass of removed controllers Typical Use Maintain communication in redundant ring topologies Systems Used with ABB modular rack/withdrawable control modules (e.g., MC510)

Technical Parameters Specification Details Product Type Digital Input Module for PLC I/O system Model / Part Number DI562 (e.g., 1TNE968902R2102) Brand ABB PLC System Compatibility AC500‑eCo / S500‑eCo I/O modules family Number of Digital Inputs 16 channels Input Type Sink/Source (configurable) Nominal Input Voltage 24 V DC Maximum Input Voltage 0 … 30 V Input Current (typ.) ~5 mA per channel Response/Delay Time ~8 ms (typical) Input Signal Range Compatible with standard 24 V DC discrete signals Status Indicators LED indicators for each input channel Isolation Group isolation between channels and logic Connection Type Pluggable terminal/cage connectors Degree of Protection IP20 Operating Temperature 0 … +60 °C Storage Temperature -40 … +70 °C Dimensions (approx.) 135 × 34 × 74 mm (length × width × height) Weight ~0.12 kg

Technical Parameters Specification Details Product Type Programmable Logic Controller (PLC) CPU Module Model / Part Number PM554‑TP‑ETH (1SAP120600R0071) PLC Series ABB AC500‑eCo Program Memory ~128 kB Flash Digital Inputs (DI) 8 channels (24 V DC) Digital Outputs (DO) 6 channels (transistor type) Power Supply 24 V DC nominal Current Consumption (typ.) ~70 mA from 24 V DC Current Consumption (max.) ~190 mA from 24 V DC Power Dissipation ~3.3 W Communication Interfaces Integrated Ethernet (RJ45), RS‑485 (serial) Expansion Slots 2 option I/O slots (support additional I/O modules) Programming ABB Automation Builder (IEC 61131‑3 languages) Mounting DIN‑rail or panel mount with removable terminal blocks Typical Operating Temp. Industrial standard range Protection Rating IP20 (typical for PLC modules) Weight ~0.3 kg Typical Applications Machine control, panel automation, logic control, remote communication Network Support Ethernet communication for programming, data exchange, and integration with SCADA/IIoT

Technical Parameters Specification Details (Typical) Product Type Test & Programming Unit for Trip Units Compatible Trip Units Ekip Touch, Ekip DIP, Ekip LSI/LSIG, and other Ekip series on Tmax XT2, XT4, XT5, XT7 breakers Compatible Breaker Families ABB SACE Tmax (XT2, XT4, XT5, XT7), Emax 2 air circuit breakers Primary Function Program, test, and monitor electronic trip unit settings Connection Interfaces Front test/programming port on trip unit or communication adapter Software Support Works with Ekip Connect (PC application) for advanced configuration and diagnostics Operation Modes Point‑to‑point or network communication with trip units Functions Supported Parameter configuration, protection test routines, measurement display, logging and diagnostics Power Supply Powered from the trip unit connection or dedicated supply (depending on setup) Portability Handheld/portable for field use Typical Applications Commissioning, installation verification, field testing, maintenance

Technical Parameters Specification Details Product Universal Motor Controller Model / Part Number 1SAJ530000R1100 (UMC100.3 UC) Supply Voltage (Control) 110–240 V AC/DC Rated Motor Current Up to 63 A (adjustable) Main Circuit Rated Voltage Up to ~690–1000 V AC Digital Inputs (DI) 6 digital inputs Digital Outputs (DO) 4 digital outputs PTC Input Yes (for thermal sensor/overheat detection) Communication Interfaces available for fieldbus or network via expansion modules Operating Temperature 0 °C to +60 °C Storage Temperature −25 °C to +70 °C Degree of Protection IP20 Dimensions (W×H×D) ~70 × 106 × 107 mm Weight ~315 g Shock/Vibration IEC standard shock and vibration resistance Standard Mounting Panel or DIN‑rail as part of motor control cabinet Typical Applications Motor start/stop, overload protection, automation logic output

Technical Parameters Specification Typical Details Product Type Digital Output Module (“DOM”) Function Provides discrete ON/OFF output signals to field devices Output Type Transistor/TTL digital outputs (sink/source depending on variant) Output Voltage Nominal 24 V DC (typical industrial standard) Output Current Typically ≤ 0.5 A per channel (varies by module type) Number of Channels Multiple binary outputs (e.g., 8–16 outputs on common modules) Signal Type Sourcing or sinking digital signals Protection & Diagnostics Short‑circuit / over‑temperature protection; status LEDs on many modules Mounting DIN‑rail or backplane rack mounted Isolation Optically isolated channels or group isolation in many designs Application Driving relays, actuators, contactors, lamps, alarms Operating Environment Industrial panel, control cabinet or distributed I/O location Standards Compliance IEC / EN industrial automation I/O module standards Typical Use Cases Process control, machine automation, smart grid I/O expansion

Technical Parameters Specification Details Product Type Low‑Voltage Molded Case Circuit Breaker (MCCB) Series / Model Tmax XT5L 400 Rated Current (In) 400 A Number of Poles 3‑pole or 4‑pole options Frame Size XT5 (larger industrial frame) Rated Operational Voltage (Ue) Up to 690 V AC / 600 V DC Standards Compliance UL/CSA certified construction and performance Trip Unit Options Thermomagnetic (TMA/MCP) or electronic (Ekip DIP, Ekip Touch, LSIG variants) Interrupting Rating 100 kA at 480 V AC (typical “L” frame rating) Terminal Type Front terminals (FF style) Installation Type Fixed mounted in panels or switchboards Auxiliary / Accessories Optional auxiliary contacts, shunt trip, undervoltage release, communication modules Operational Uses Main protection, feeder protection, motor and load isolation Typical Applications Industrial power distribution, commercial building electrical panels, heavy machinery protection

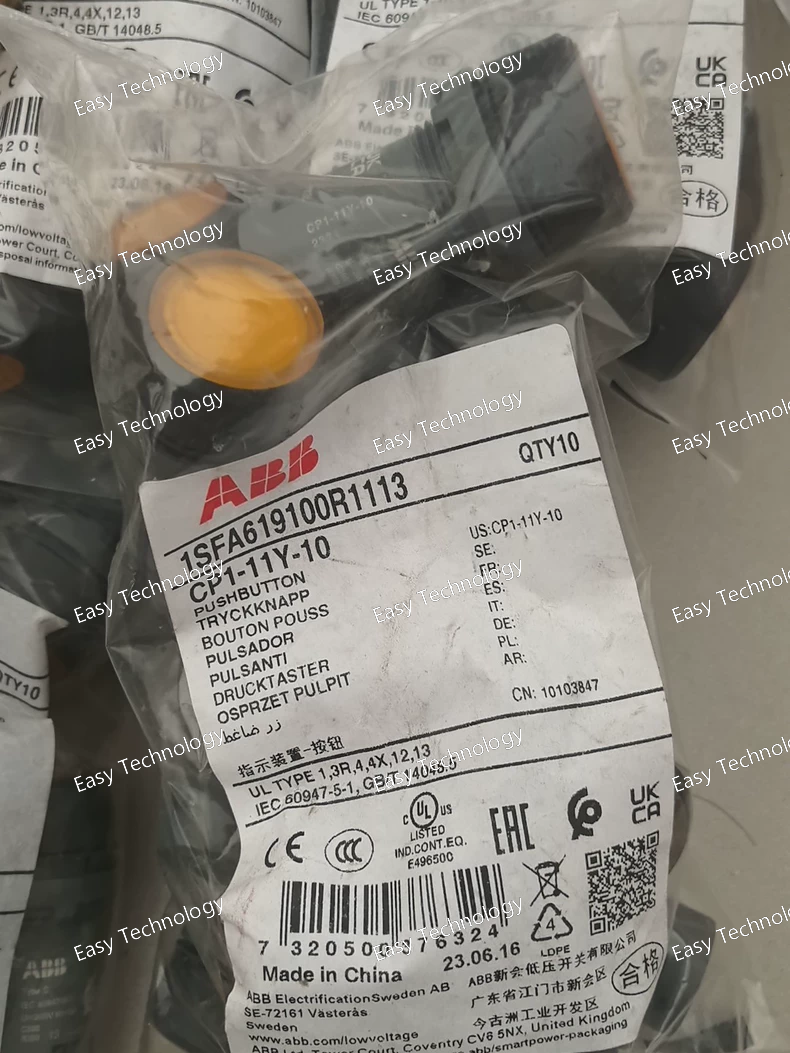

Technical Parameters Specification Details Product Type Compact Illuminated Pushbutton Model / Part Number CP1‑11Y‑10 Brand ABB Actuator Style Flush momentary pushbutton Illumination Yes – LED (24 V AC/DC) Button Color Yellow Bezel / Housing Black plastic Contact Configuration 1 Normally Open (1NO) Rated Operational Voltage 24 V AC/DC for illumination and control Rated Insulation Voltage (Ui) 300 V Rated Impulse Withstand Voltage (Uimp) 6 kV Contact Rating (Typical) ~1 A @ 240 V AC, 0.3 A @ 24 V DC (control circuit limits) Rated Frequency 50/60 Hz Mechanical Life ~0.5 million operations Connection Type Screw terminals / screw clamp Degree of Front Protection IP66 / IP67 / IP69K Terminal Protection IP20 Panel Cutout Size Standard 22 mm diameter Ambient Operating Temp. −25 °C to +70 °C Storage Temp. −40 °C to +85 °C Standards Compliance IEC/EN pilot device standards (e.g., IEC 60947‑5‑1 / IEC 60947‑5‑5) Typical Applications Control panels, machine start/stop stations, indicator circuits, safety and automation interfaces