PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

Specifications Parameter Specification Supply Voltage 24 V DC (±20%) via host device Power Consumption 2.5 W typical, 3.5 W maximum Current Consumption 100 mA typical at 24 V DC Isolation 500 V AC (communication to power circuits) PROFIBUS Interface RS-485 isolated, 9-pin D-Sub female connector Baud Rate 9.6 kbit/s to 12 Mbit/s (auto-detect) PROFIBUS Address 1-125 (set via rotary switch 0-99 + software 100-125) Protocol PROFIBUS DP-V1 (slave) GSD File ABB0809.GSD (specific version required) Data Consistency 8 bytes input / 8 bytes output (configurable) Update Time <10 ms (at 12 Mbit/s) 3. Mechanical Specifications Parameter Specification Dimensions (W×H×D) 45 × 90 × 62 mm (1.77 × 3.54 × 2.44 in) Weight 120 g (0.26 lb) Housing Material Polycarbonate (UL94 V-0) Protection Degree IP20 (for mounting in enclosure) Mounting Direct plug-in to PSR soft starter control unit Connector 9-pin D-sub female (PROFIBUS), screw terminals (aux power) Operating Position Any orientation allowed Color ABB standard gray (RAL 7035) 4. Environmental Specifications Parameter Specification Operating Temperature -20°C to +60°C (-4°F to +140°F) Storage Temperature -40°C to +85°C (-40°F to +185°F) Relative Humidity 5% to 95% non-condensing Altitude ≤2000 m (6560 ft) above sea level Vibration Resistance 5-150 Hz, 1g (IEC 60068-2-6) Shock Resistance 15g, 11ms half-sine (IEC 60068-2-27) Pollution Degree 2 (IEC 60664-1)

Specifications Parameter Specification Supply Voltage 24 V DC (powered from host device) Power Consumption Typically 2-5 W Isolation Voltage 500 V AC (input to output, typical) Communication Speed If PROFIBUS DP: 9.6 kbit/s - 12 Mbit/s If Modbus RTU: 1200 - 115200 baud Data Update Rate ≤ 10 ms (typical for motor data) Number of Process Data Words 4-8 input / 4-8 output words (typical) 3. Mechanical Specifications Parameter Specification Dimensions (W×H×D) Approx. 45 × 90 × 60 mm (estimate) Weight 100-150 g Housing Material Polycarbonate (PC) or Polyamide (PA) Protection Degree IP20 (for enclosure mounting) Mounting Method Direct plug-in to host device Connection Type 9-pin D-sub (if PROFIBUS) or terminal block Operating Position Any (module orientation independent) 4. Environmental Specifications Parameter Specification Operating Temperature -20°C to +60°C (-4°F to +140°F) Storage Temperature -40°C to +85°C (-40°F to +185°F) Relative Humidity 5% to 95% (non-condensing) Altitude ≤ 2000 m above sea level Vibration Resistance 5-2000 Hz, 1g (IEC 60068-2-6) Shock Resistance 15g, 11ms (IEC 60068-2-27) Pollution Degree 2 (IEC 60664-1)

Technical Specifications Parameter Specification Product Code UL-740A-R2A-B024-021 Product Family ABB Symphony / IndustrialIT 800xA / S800 I/O System Module Type Redundant Power Supply Unit Input Voltage 100-240V AC, 50/60 Hz (Universal Input) Output Voltage 24V DC (regulated, for field instruments and I/O modules) Output Current 10A (per module, total 20A in redundant configuration) Redundancy N+1 Redundant Configuration supported (hot-swappable) Efficiency >85% (typical) Protection Overload, Short-circuit, Overvoltage protection Isolation 1500V AC input-to-output isolation Cooling Convection cooling (fanless) Operating Temperature 0°C to +60°C (32°F to 140°F) Relative Humidity 5% to 95% non-condensing MTBF >200,000 hours (calculated per MIL-HDBK-217F) Standards UL 508, CSA C22.2 No. 14, IEC 61131-2, CE, RoHS

Technical Specifications Parameter Specification Product Code PSE142-600-70 Series ABB PSE Electronic Motor Starters Rated Operational Current (Iₑ) 142 A (at 400V, 40°C ambient) Supply Voltage 3-phase, 380 - 690 V AC, 50/60 Hz Motor Power Range Approx. 75 kW (at 400V) Control Supply Voltage (Us) Selectable: 24 V AC/DC, 48-130 V AC, 110-130 V DC, or 200-240 V AC/DC Starting Method Voltage ramp with adjustable initial torque (kick start) and ramp time Starting Current Adjustable, typically up to 400% of motor Full Load Current (FLC) Stopping Method Coast stop (standard); programmable soft stop (optional) Motor Protection Class 10 electronic overload protection, phase loss/imbalance, jam protection, underload, PTC thermistor input Enclosure IP00 (Open Type) for panel mounting Ambient Temperature -25°C to +60°C (operating), derating above +40°C Communication Optional plug-in communication modules (PROFIBUS DP, Modbus RTU, DeviceNet) Standards & Approvals IEC/EN 60947-4-2, UL 508, CE, cULus

Technical Specifications Parameter Specification Product Code PSTX170-600-70 Series ABB PSTX Medium Voltage Soft Starters Rated Voltage 3300 V / 6000 V (switch-selectable) Rated Current 170 A (continuous at 40°C) Starting Current Adjustable, typically 200% - 450% of motor Full Load Current (FLC) Motor Power Range Approx. 850 - 1120 kW (dependent on voltage & motor PF) Control Supply Voltage 110-120V AC or 220-240V AC, 50/60 Hz (configurable) Starting Time Adjustable from 5 to 120 seconds Stopping Time Adjustable soft-stop (optional) Cooling Method Forced air cooling (integrated fans) Enclosure IP00 / Open Type (for cabinet installation) Ambient Temperature 0°C to +40°C (32°F to 104°F) for full rating; up to +50°C (122°F) with derating Altitude Up to 1000 m (3280 ft) without derating Standards & Approvals IEC, UL, CSA, CE; compliant with IEC 60947-4-2

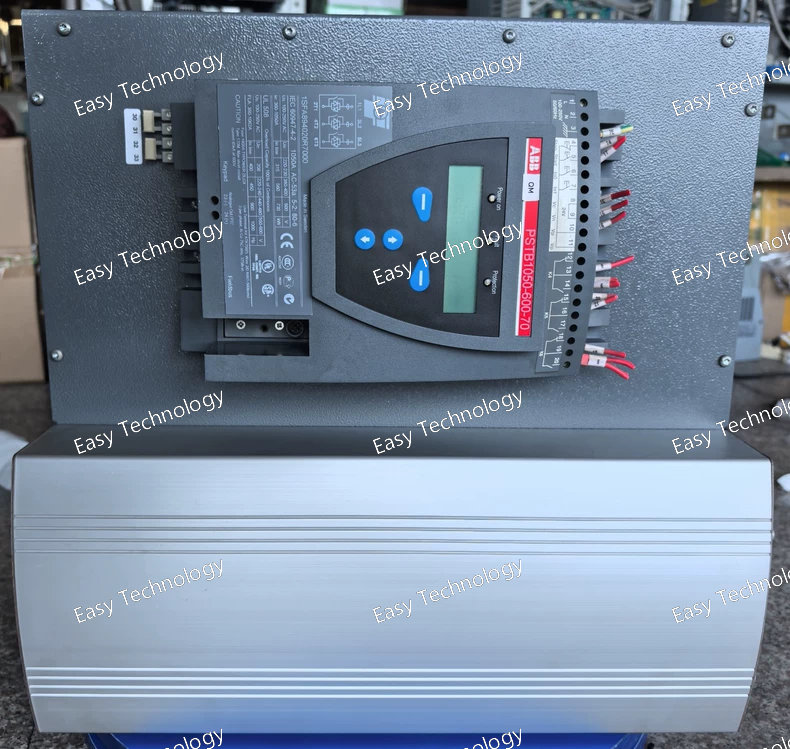

Technical Specifications Parameter Specification Product Code PSTB1050-600-70 Series ABB PSTB Medium Voltage Soft Starters Rated Voltage 3300 V / 6000 V (switch-selectable) Rated Current 1050 A (continuous at 40°C) Starting Current Adjustable, typically 200% - 500% of motor Full Load Current (FLC) Motor Power Range Approx. 5500 - 8000 kW (dependent on voltage, motor PF & efficiency) Control Supply Voltage 110-120V AC or 220-240V AC, 50/60 Hz (configurable) Starting Time Adjustable from 10 to 120 seconds (or more for very high inertia loads) Stopping Time Adjustable soft-stop (optional) Cooling Method Forced air cooling with high-capacity fans; may require external ducting. Enclosure IP00 / Open Type (intended for installation in a robust, contractor-suppiled floor-standing cubicle) Ambient Temperature 0°C to +40°C (32°F to 104°F) for full rating; derating up to +50°C (122°F) Altitude Up to 1000 m (3280 ft) without derating Standards & Approvals IEC, IEEE, UL, CSA, CE; compliant with IEC 60947-4-2, IEEE 519

Technical Specifications Parameter Specification Product Code PSE85-600-70 Series ABB PSE Electronic Motor Starters Rated Operational Current (Iₑ) 85 A (at 400V, 40°C ambient) Supply Voltage 3-phase, 380 - 690 V AC, 50/60 Hz Motor Power Range Approx. 45 - 55 kW (at 400V) Control Supply Voltage (Us) Selectable: 24 V AC/DC, 48-130 V AC, 110-130 V DC, or 200-240 V AC/DC Starting Method Voltage ramp with adjustable initial torque and ramp time. Starting Current Adjustable, typically up to 400% of motor Full Load Current (FLC). Stopping Method Coast stop (standard); programmable soft stop (optional). Motor Protection Class 10 electronic overload protection (I²t), phase loss/imbalance, jam/blocked rotor, underload, and PTC thermistor input for direct motor temperature monitoring. Enclosure IP00 (Open Type) for mounting inside a customer-supplied control cabinet. Ambient Temperature -25°C to +60°C (operating), with derating required above +40°C. Communication Via optional plug-in communication modules (e.g., PROFIBUS DP, Modbus RTU, DeviceNet). Standards & Approvals IEC/EN 60947-4-2, UL 508, CE, cULus listed.

Technical Specifications Parameter Specification Product Code PSTX250-600-70 Series ABB PSTX Medium Voltage Soft Starters Rated Voltage 3300 V / 6000 V (switch-selectable) Rated Current 250 A (continuous at 40°C) Starting Current Adjustable, typically 200% - 450% of motor FLC (Full Load Current) Motor Power Range Approx. 1400 - 1850 kW (dependent on voltage & motor characteristics) Control Supply Voltage 110-120V AC or 220-240V AC, 50/60 Hz (configurable) Starting Time Adjustable from 5 to 120 seconds Stopping Time Adjustable soft-stop (optional, 5 to 120 seconds) Cooling Method Forced air cooling (integrated fans) Enclosure IP00 / Open Type (for cabinet installation) Ambient Temperature 0°C to +40°C (32°F to 104°F) for full rating; up to +50°C (122°F) with derating Altitude Up to 1000 m (3280 ft) without derating Standards & Approvals IEC, UL, CSA, CE; compliant with IEC 60947-4-2

Technical Specifications Parameter Specification Product Code PSE60-600-70 Series ABB PSE Electronic Motor Starters Rated Operational Current (Iₑ) 60 A (at 400V, 40°C) Supply Voltage 3-phase, 380 - 690 V AC, 50/60 Hz Motor Power Range Approx. 30 - 37 kW (at 400V) Control Supply Voltage (Us) 24 V AC/DC, 48-130 V AC, 110-130 V DC, or 200-240 V AC/DC (selectable) Starting Method Voltage ramp with adjustable initial torque (kick start) and ramp time. Starting Current Adjustable, typically 200% - 400% of motor FLC. Stopping Method Coast stop (standard); Soft stop (optional, adjustable). Motor Protection Class 10 electronic overload, phase loss/imbalance, jam protection, underload, PTC thermistor input. Enclosure IP00 (Open Type) for panel mounting. Ambient Temperature -25°C to +60°C (operating), derating above +40°C. Communication Via optional plug-in modules (e.g., PROFIBUS DP, Modbus RTU). Standards & Approvals IEC/EN 60947-4-2, UL 508, CE, cULus.

Technical Specifications Parameter Specification Product Code PSE170-600-70 Series ABB PSE Electronic Motor Starters Rated Operational Current (Iₑ) 170 A (at 400V, 40°C) Rated Supply Voltage 3-phase, 380 - 690 V AC, 50/60 Hz Motor Power Range Approx. 90 - 110 kW (at 400V) Control Supply Voltage (Us) 24 V AC/DC, 48-130 V AC, 110-130 V DC, or 200-240 V AC/DC (selectable) Starting Method Voltage Ramp with adjustable initial torque and ramp time. Starting Current Adjustable, typically up to 400% of motor FLC (Full Load Current). Stopping Method Coast stop (default) or optional soft stop. Motor Protection Class 10 electronic overload protection, phase imbalance, jam/blocked rotor, underload, PTC thermistor input. Enclosure IP00 (Open Type) for mounting in a customer-supplied control cabinet. Ambient Temperature -25°C to +60°C (derating above +40°C) Communication Optional plug-in communication modules (e.g., PROFIBUS DP, Modbus RTU, DeviceNet). Standards IEC/EN 60947-4-2, UL 508, CE, cULus.

Technical Specifications Parameter Specification Product Code PSE210-600-70 Series ABB PSE Electronic Motor Starters Rated Operational Current (Iₑ) 210 A (at 400V, 40°C) Rated Supply Voltage 3-phase, 380 - 690 V AC, 50/60 Hz Motor Power Range Approx. 110 - 132 kW (at 400V) Control Supply Voltage (Us) 24 V AC/DC, 48-130 V AC, 110-130 V DC, or 200-240 V AC/DC (selectable) Starting Method Voltage Ramp with adjustable initial torque and ramp time. Starting Current Adjustable, typically up to 400% of motor FLC (Full Load Current). Stopping Method Coast stop (default) or optional soft stop. Motor Protection Class 10 electronic overload protection, phase imbalance, jam/blocked rotor, underload, PTC thermistor input. Enclosure IP00 (Open Type) for mounting in a customer-supplied control cabinet. Ambient Temperature -25°C to +60°C (derating above +40°C) Communication Optional plug-in communication modules (e.g., PROFIBUS DP, Modbus RTU, DeviceNet). Standards IEC/EN 60947-4-2, UL 508, CE, cULus.

Technical Specifications Category Likely Specification Compatibility Designed for specific series of ABB PSR (Soft Starter Combination) or MMP (Modular Motor Protector) units. The exact host device model(s) must be verified. Function Type Most Likely: A communication interface module (e.g., for PROFIBUS DP-V1 or Modbus RTU). Alternatively: An application configuration module for a specific industry/load type. Physical Interface Standardized plug connector that mates with a slot on the host device. Status Indication May include LED indicators for power, communication activity, or module status. Power Supply Powered directly from the host device (typically 24V DC derived from the main control circuit). Environmental Rated for standard industrial panel environments (IP20). Certifications Inherits safety and EMC certifications from the host system (CE, UL, cUL). 4. Key Features & Purpose System Integration: Enables the motor starter or protector to communicate with higher-level automation systems (PLCs, DCS, SCADA). Quick Commissioning: Application modules allow for rapid setup by loading pre-optimized parameter sets for common motor-driven equipment. Modularity: Allows users to select and pay only for the required functionality, with the flexibility to upgrade later. Diagnostics: Communication modules often provide enhanced diagnostic data access from the network. 5. Common Applications This module is used as a critical interface or configuration tool within motor control centers (MCCs) and automated systems: Integration into PROFIBUS DP Networks: Connecting a soft starter or motor protector to a Siemens PLC or similar control system. Pump Station Control: Using an application module pre-configured for pump control logic (soft stop, pump cleaning cycle, alternation). Fan Control Systems: Applying optimized parameters for centrifugal fan loads.