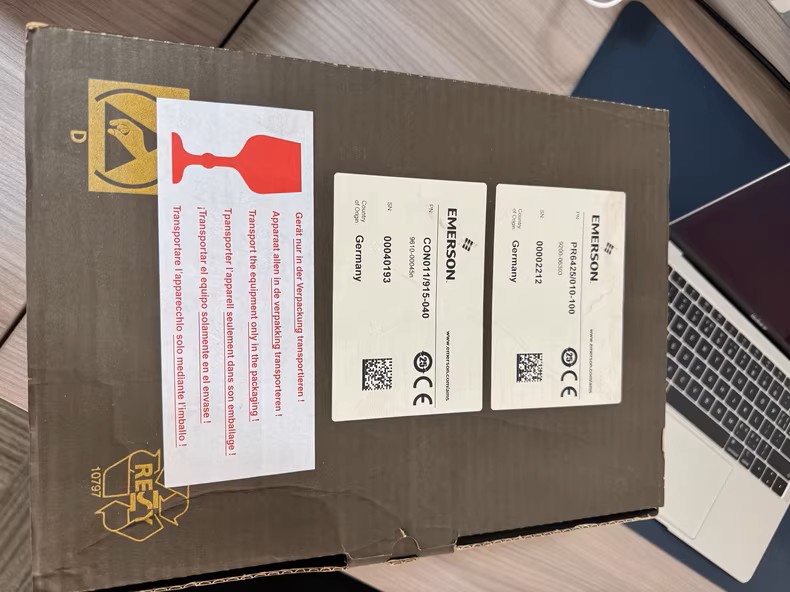

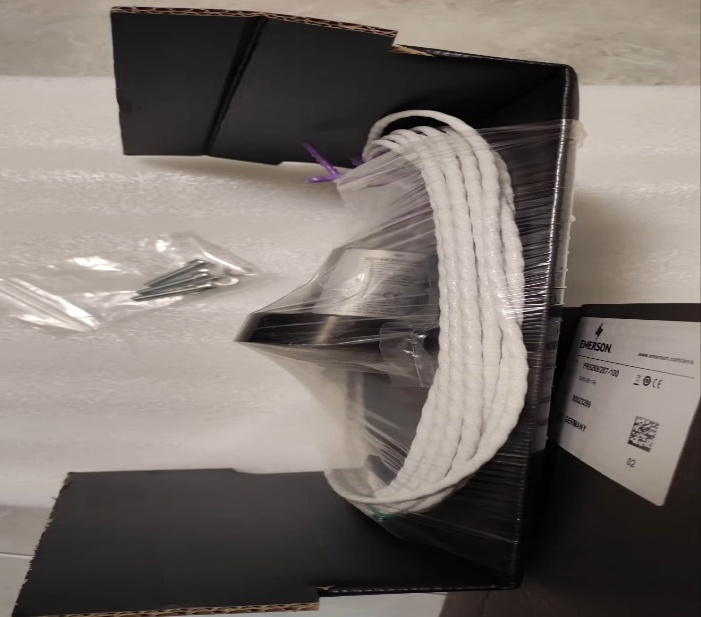

PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

EPRO

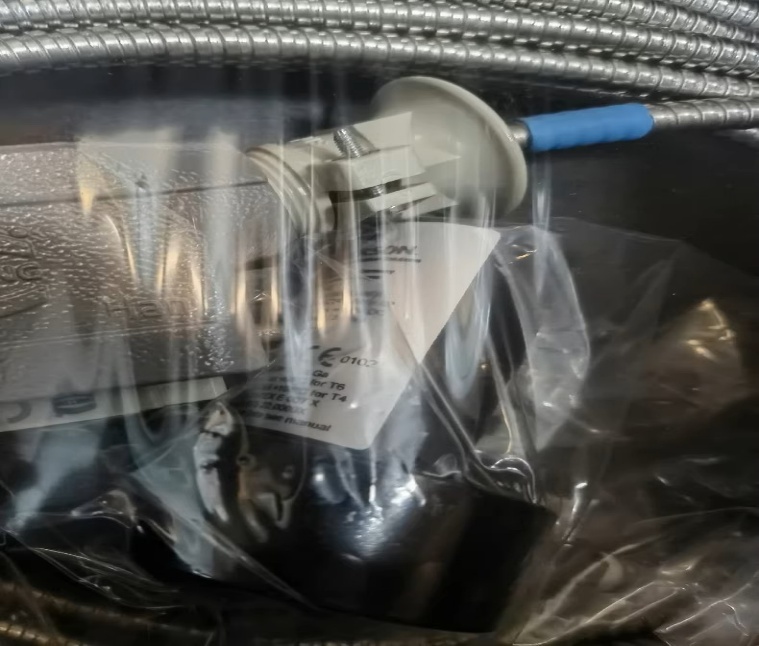

Key Features: Reliable shaft vibration and position monitoring (0.5-2.5mm range) 8mm diameter probe with stainless steel construction Wide frequency response (0-10kHz) for dynamic measurements High temperature operation (up to +150°C probe rating) ATEX/IECEx certified versions available for hazardous areas Technical Highlights: Standard sensitivity: 8mV/μm -24VDC power supply operation IP67 protection rating Military-grade connectors for secure connections Typical Applications: Gas/steam turbine monitoring Compressor protection systems Bearing condition monitoring Rotor position measurement This system meets API 670 and ISO 7919 standards, making it suitable for critical machinery protection in power generation, oil & gas, and other heavy industries. The PR 6426/010-100 offers excellent reliability and accuracy for predictive maintenance programs.

94

EPRO

Key Features: Dual-function monitoring: Simultaneously measures shaft vibration (0-500 µm) and axial position (±1mm to ±5mm) Advanced sensor compatibility: Works with industry-standard 8mm/11mm eddy current probes Flexible outputs: Offers 4-20mA, ±10V analog signals and Modbus RTU communication Multi-level protection: Configurable Warning/Danger alarms with relay outputs Wide operating range: Functions in extreme temperatures (-30°C to +70°C) with IP66/IP67 protection Typical Applications: Continuous monitoring of turbines, compressors and large rotating equipment Machinery protection in power generation and oil & gas industries Predictive maintenance programs for critical assets

204

EPRO

Key Features: ✔ Multi-Sensor Support – Works with eddy current probes, velocity sensors, and accelerometers ✔ Dual-Channel Input – Monitors two independent measurement points simultaneously ✔ Programmable Alarms – Configurable Warning/Danger thresholds with relay outputs ✔ Flexible Outputs – 4–20 mA, ±10 V, RS-485 (Modbus), and optional PROFIBUS ✔ Wide Frequency Range – Covers 0.1 Hz – 10 kHz (displacement) and 1 Hz – 1 kHz (velocity/acceleration) ✔ Industrial Durability – IP65-rated enclosure, operates in -20°C to +70°C Typical Applications: Turbines, compressors, pumps, and motors Condition monitoring & predictive maintenance Integration with PLC/DCS systems The EZ1000 enhances operational safety and reduces downtime by providing real-time vibration analysis and alarm-based protection.

489

EPRO

Key Features: Dual-channel input for simultaneous monitoring of two axes. Wide frequency range (0.5 Hz – 10 kHz) for diverse applications. Configurable alarms (Warning/Danger) with relay outputs for machine protection. Analog (4–20 mA / ±10 V) and digital (RS-485/Modbus) outputs for integration with control systems. Robust design with IP65 protection, suitable for harsh industrial environments. Typical Applications: Turbines, compressors, pumps, and motors. Predictive maintenance and condition monitoring. The EZ1900-070 ensures reliable vibration analysis and machine safety, helping prevent unplanned downtime. For detailed specifications, refer to the official EPRO documentation.

183

EPRO

Core Function: Compact signal conditioning module for converting eddy current probe signals to standardized 4-20mA output. Key Specifications: • Input: -2 to -20V DC (from EPRO PR642x probes) • Output: Isolated 4-20mA (linear to displacement) • Accuracy: ±0.5% FS • Load Capacity: 0-500Ω Electrical Characteristics: ✓ 24V DC power supply (±10%) ✓ <5W power consumption ✓ 100kΩ input impedance Environmental Ratings: Operating Temp: -20°C to +70°C Humidity: 5-95% RH (non-condensing) Protection: IP20 Configuration & Indicators: • DIP switch adjustable range • LED status indicators (power/signal) • DIN-rail mounting Compatibility: Works with EPRO MMS6000/A6500 systems Supports PR6423/PR6426 probe series Typical Applications: Turbine vibration monitoring Compressor displacement systems PLC/DCS integration Installation Note: Requires shielded cabling for noise protection

315

EPRO

Core Function: Extended-range eddy current sensor for large-displacement monitoring in industrial applications. Key Specifications: • Sensitivity: 1.1 mV/µm (±5%) • Wide Measurement Range: 0-10mm (10,000µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC Robust Design: ✓ 8mm probe diameter ✓ M10×1 threaded mounting ✓ -40°C to +150°C operation ✓ 4MPa pressure rating Measurement Performance: Default calibration for AISI 4140 steel Linear range: 3-7mm (60% of full scale) Typical accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 systems • Requires signal conditioning for optimal performance • 5m high-temp cable (standard) Typical Applications: Large turbine shaft monitoring Industrial compressor position measurement Heavy machinery displacement monitoring Special Notes: /002 variant features enhanced environmental tolerance Lower sensitivity (1.1mV/µm) optimized for wide-range measurement Requires proper signal amplification for small displacement resolution Compliance: Meets API 670 machinery protection standards

287

EPRO

Core Function: High-sensitivity eddy current displacement sensor for precision machinery monitoring in critical applications. Key Specifications: • Sensitivity: 10.0 mV/µm (±5%) • Measurement Range: 0-1.0mm (1000µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC linear signal Robust Design: ✓ 11mm heavy-duty probe ✓ M14×1.5 threaded mounting ✓ -40°C to +120°C operation ✓ 20g vibration resistance ✓ 4MPa pressure rating Measurement Performance: Default calibration for AISI 4140 steel Linear range: 60% of full scale Accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 systems • Standard 5m/9m cable options • CON021 quick-disconnect available Typical Applications: Turbine shaft vibration monitoring Compressor thrust bearing measurement Precision machinery protection Special Features: /202 variant optimized for high-sensitivity applications Enhanced signal resolution for critical measurements Industrial-grade durability Compliance: Meets API 670 machinery protection standards

272

EPRO

Core Function: Industrial-grade eddy current sensor for precision displacement monitoring in harsh operating environments. Key Specifications: • Sensitivity: 4.1 mV/µm (±5%) • Measurement Range: 0-2.0mm (2000µm) • Frequency Response: DC to 10kHz • Extended Temp Range: -40°C to +150°C Robust Construction: ✓ 8mm probe diameter with M10×1 threading ✓ Enhanced vibration resistance (25g) ✓ 4MPa pressure rating ✓ High-temperature cable option Measurement Performance: Default calibration for AISI 4140 steel Linear operating range: 60% of full scale ±1% FS typical accuracy System Integration: • Compatible with EPRO MMS6000 systems • 5m mineral-insulated cable (standard) • ATEX versions available Typical Applications: Steam turbine shaft monitoring Offshore compressor protection High-vibration industrial equipment Special Features: /002 variant designed for extreme environments Optimized for reliable performance under: High temperatures Severe vibration Pressure fluctuations Compliance: Meets API 670 machinery protection standards

669

EPRO

Core Function: High-sensitivity eddy current sensor for precision displacement monitoring in critical rotating equipment. Key Specifications: • Sensitivity: 10.0 mV/µm (±5%) • Measurement Range: 0-1.0mm (1000µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC linear signal Robust Design: ✓ 11mm heavy-duty probe ✓ M14×1.5 threaded mounting ✓ -40°C to +120°C operation ✓ 20g vibration resistance ✓ 4MPa pressure rating Measurement Performance: Target: AISI 4140 steel Linear range: 60% of full scale Accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 systems • Standard 5m/9m cable options • CON021 quick-disconnect available Typical Applications: Turbine shaft vibration monitoring Compressor thrust position measurement Precision bearing clearance monitoring Special Features: /207 variant optimized for high-sensitivity applications Enhanced signal resolution for critical measurements Industrial-grade durability Compliance: Meets API 670 machinery protection standards

163

EPRO

Core Function: Heavy-duty eddy current sensor for extreme-condition displacement monitoring in critical rotating equipment. Key Specifications: • Sensitivity: 8.0 mV/µm (±5%) • Measurement Range: 0-2.0mm (2000µm) • Frequency Response: DC to 10kHz • Extended Temp Range: -40°C to +175°C (peak 200°C) Robust Construction: ✓ 11mm ruggedized probe ✓ M14×1.5 threaded mounting ✓ 6MPa pressure rating ✓ 25g vibration resistance ✓ Mineral-insulated high-temp cable Measurement Performance: Target: AISI 4140 steel Linear range: 60% of full scale Accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 systems • Hazardous area options (ATEX) • API 670 compliant Typical Applications: High-pressure steam turbine monitoring Offshore gas compressor protection Extreme-environment machinery Special Notes: /303 designation indicates enhanced environmental capability Requires high-temperature installation procedures Not for use with standard extension cables

923

EPRO

Core Function: Heavy-duty eddy current displacement sensor for critical machinery protection applications. Key Specifications: • Sensitivity: 8.0 mV/µm (±5%) • Measurement Range: 0-2.0mm (2000µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC linear signal Robust Mechanical Design: ✓ 11mm large-diameter probe ✓ M14×1.5 threaded mounting ✓ -40°C to +150°C operation (sensor head) ✓ 20g vibration resistance ✓ 4MPa pressure rating Measurement Performance: Target material: AISI 4140 steel Linear range: 60% of full scale Typical accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 systems • Standard 5m/9m cable options • CON021 quick-disconnect available Typical Applications: Large steam/gas turbine monitoring Heavy compressor thrust measurement Critical rotating equipment protection Special Features: Enhanced durability for harsh environments Large probe design for stable measurements Extended temperature capability Compliance: Meets API 670 machinery protection standards

73

EPRO

Core Function: Industrial IEPE accelerometer for machinery vibration monitoring in predictive maintenance systems. Key Specifications: • Sensitivity: 10 mV/g (±5%) • Range: ±50g peak • Frequency Response: 0.5Hz-5kHz (±10%) • Resonant Frequency: >25kHz Robust Construction: ✓ Stainless steel 316L housing ✓ M6 threaded mounting ✓ IP67 environmental protection ✓ -40°C to +120°C operation Electrical Characteristics: IEPE output (2-20mA constant current) 18-30V DC excitation required 5m integral cable (standard) Measurement Features: Low-noise signal output 500g shock resistance <5% transverse sensitivity Typical Applications: Rotating equipment bearing monitoring Gearbox vibration analysis Compressor/fan mechanical health assessment Compliance: ISO 10816 vibration standards API 670 machinery protection

361