PRODUCT

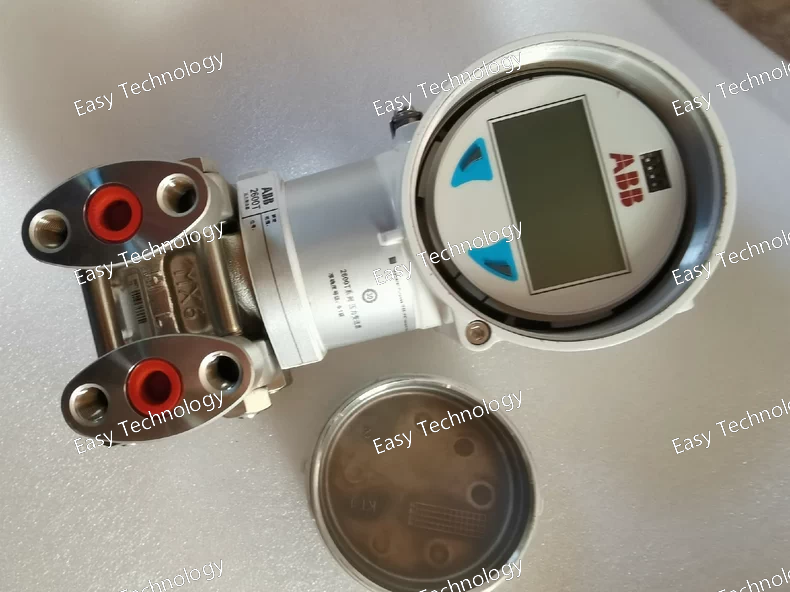

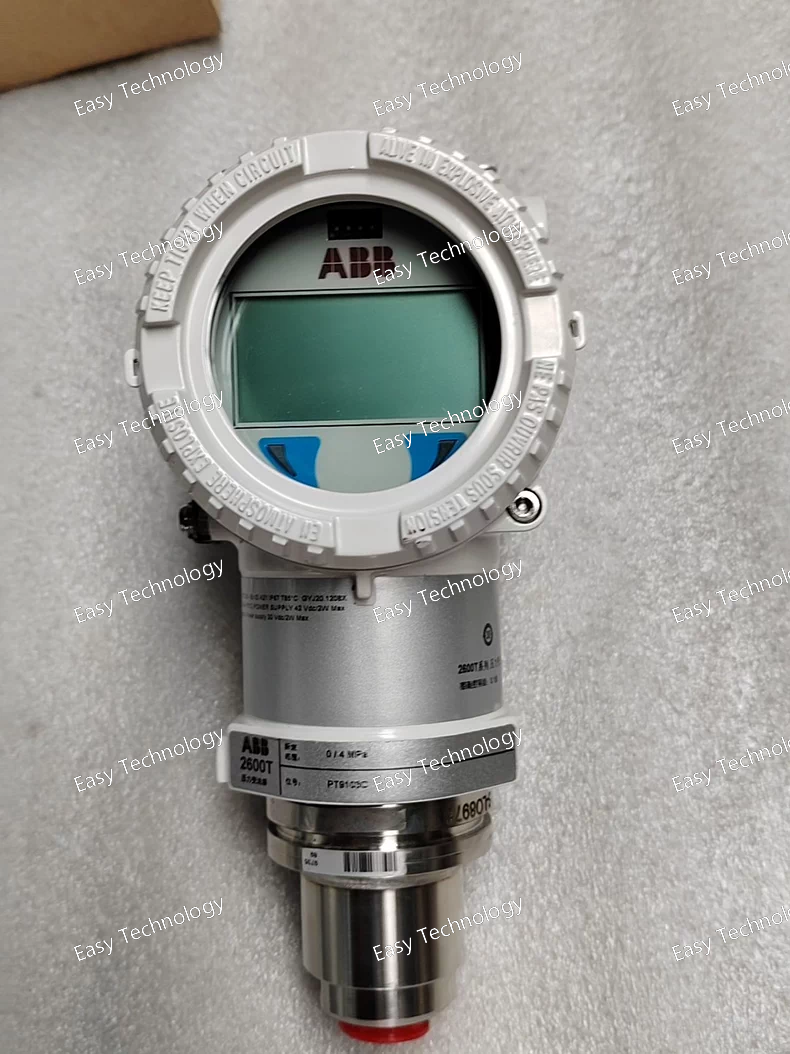

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

Performance Specifications (General for 266DSH) Base accuracy: from ±0.06% of calibrated span (depending on sensor/span configuration) Span limits (differential pressure span options): from as low as 0.05 kPa up to 16,000 kPa depending on sensor option — wide flexibility. Turn-down ratio: up to 100:1 (depending on configuration) Static (line) pressure capability: depending on sensor and static-pressure rating; typical static pressure ratings up to tens of MPa for standard static versions — able to withstand high line pressures even while measuring small differential pressures. Over-/Proof pressure capability: Designed to handle high static pressures safely; in standard static versions the transmitter can be exposed to high overpressure without leaking (static pressure rating varies with sensor / materials). Output / Communication Options: Standard 4–20 mA + HART digital communication. Other fieldbus/digital protocols (e.g. FOUNDATION Fieldbus, PROFIBUS PA) are available depending on ordering code. Configuration & Display: Configuration can be done locally via integrated LCD + keypad (TTG) or via external HART / fieldbus communicator or PC. Diagnostics & Safety: Built-in diagnostics including Plugged-Impulse-Line Detection (PILD). Suitable for SIL2 / SIL3 safety-critical applications. Environmental / Robustness: Suitable for harsh process / ambient conditions; designed for industrial environments with vibration, variable temperature, possibly dusty or wet atmospheres; meets relevant industrial standards for electromagnetic compatibility, ingress protection (dust/water), shock & vibration, static-pressure endurance, etc. Units / Output Scaling: Supports wide range of engineering units for pressure differential (kPa, Pa, MPa, bar, psi, inH₂O, ftH₂O, mmHg, atm, etc.) depending on configuration and communication protocol. Flexible Configuration: The transmitter is factory-calibrated to customer-specified span / range; but all parameters (Lower Range Limit, Upper Range Limit, engineering units, damping, tag name, static pressure rating, flange type/material, O-rings, vent/drain valve, optional display, certificates etc.) can be configured later via communicator or PC.

Technical Parameters General Type: Gauge pressure transmitter Model: 266HSH Configuration code: MSBA1 Application: Measurement of liquid, gas, or steam pressure Design: High-overload capability, long-term stability, suitable for harsh industrial environments Measurement Range Span code M: 6 to 600 kPa Turn-down ratio: Up to 100:1 Reference accuracy: ±0.06% of calibrated span Long-term stability: Typically ±0.15% of URL over 10 years Wetted Parts Code S: Diaphragm material: AISI 316L stainless steel Fill fluid: Silicone oil Compliance: NACE compatible Process Connection Code B: Connection type: 1/2-14 NPT female Material: AISI 316L stainless steel Housing / Electrical Code A: Housing material: Aluminum alloy (barrel type) Electrical connection: 1/2-14 NPT Output / Communication Code 1: Signal: 4–20 mA Communication: HART protocol Physical / Environmental Approximate weight: 2.1 kg Suitable for outdoor and industrial environments Resistant to vibration, temperature fluctuation, and overpressure

Technical Parameters General Performance Type: High-overload gauge pressure transmitter Measured media: Liquids, gases, steam Pressure range: From low spans up to 105 MPa (15,225 psi) depending on sensor option Turn-down ratio: Up to 100:1 Reference accuracy: Up to ±0.06% of calibrated span (depending on configuration) Long-term stability: Typically better than ±0.15% of URL over 10 years Output / Communication 4–20 mA with HART (standard) Optional digital protocols depending on configuration (e.g., Modbus, Profibus PA, Foundation Fieldbus, WirelessHART) Local configuration possible through Through-The-Glass (TTG) keypad without opening housing Mechanical / Materials Wetted parts: Stainless steel or other materials depending on option Diaphragm: Stainless steel or Hastelloy (varies by code) Housing: Aluminum alloy or stainless steel (barrel-type body) Typical process connection: 1/2"–14 NPT female or according to option code Display / Interface “LS” option: Integrated LCD display with local push-buttons Supports configuration, calibration, and diagnostics on site Certifications / Safety SIL2 or SIL3 capable (depending on installation), per IEC 61508 Hazardous-area approvals depending on “TB” / “EY” model options Suitable for safety-critical industrial environments Environmental Designed for extreme process and ambient conditions Wide operating temperature range High resistance to overpressure and vibration

Parameters Category Specification Communication KNX TP1 (Twisted Pair) Supply Voltage Via KNX bus (21–32 V DC, SELV) Bus Current Consumption Typically ≤ 15 mA (depends on backlight status) Display High-resolution color TFT touchscreen (main unit) Bedside Panel Backlit physical buttons with engraved/illuminated icons for Light Scene, DND, Make Up Room, Off. Programming Configured entirely via ETS (Engineering Tool Software). The bedside button functions (EZ) are mapped to KNX telegrams within the ETS project. Primary Functions • Full room control via main touchscreen (lighting, blinds, HVAC, etc.) • One-touch control of a master lighting scene via the main LS button. • Hotel-style guest functions via bedside panel: Privacy/DND, Service Request, Room Off. • Customizable graphical interface on the main screen. Protection Rating Front plate: IP20 Ambient Temperature Operation: 0 °C to +45 °C Approvals KNX Certified, CE, RoHS compliant Mounting Flush-mounted (TB), requires a deep mounting box (e.g., 60mm) to accommodate the device depth.

Parameters Category Specification Communication KNX TP1 (Twisted Pair) Supply Voltage Via KNX bus (21–32 V DC, SELV) Bus Current Consumption Max. 15 mA Display High-resolution, colour TFT touchscreen with dynamic graphics capability Programming Exclusively via ETS (Engineering Tool Software), version 5.7 or higher recommended. Core Functions • Centralized room control (lighting, blinds, HVAC) • Customizable user interface with pages, icons, and graphics • Visual feedback and status display • Scene control and scheduling capabilities Protection Rating IP20 (for indoor dry environments) Ambient Temperature Operation: 0 °C to +45 °C Storage: -25 °C to +55 °C Approvals KNX Certified, CE, RoHS compliant Mounting Surface-mounted (A7), designed to be installed on solid walls.

Parameters & Specifications Category Specification Communication KNX TP1 (Twisted Pair) bus system Supply Voltage Via KNX bus (21–32 V DC, SELV) Bus Current Consumption Typically ≤ 10 mA (approx. 170 mW) Display High-resolution colour TFT touchscreen Memory Integrated for storing custom user interfaces, graphics, and icons Programming & Commissioning Configured and programmed with the ETS (Engineering Tool Software), version 5.7 or higher recommended. Primary Functions Lighting control (on/off, dimming, scenes) Blinds/shutter control Room temperature control and display Status monitoring (windows, alarms) Navigation through custom pages Integration of third-party system status Protection Rating IP20 (for indoor use only) Ambient Temperature Operation: 0 °C to +45 °C Storage: -25 °C to +70 °C Approvals & Standards KNX Certified, CE, RoHS compliant

Parameters Category Parameter Specification / Interpretation for 266DSH BSHA1B2L1TB General Model Series 2600T Series (DST - Differential Pressure Smart Transmitter) Type Smart dP Transmitter with Local Operator Interface Output 4-20 mA DC, Two-wire, HART Protocol. Measurement Performance Measured Variable Differential Pressure (dP) Calibrated Span (BSHA1) Defined by core code. Example: 0 to 40 kPa (0.4 bar). Must be verified from official datasheet. Reference Accuracy ±0.075% of calibrated span (Typical). Long-Term Stability ±0.1% of URL per year. Turndown Ratio Up to 100:1 (Software configurable). User Interface Local Display (L1) Backlit LCD. Local Controls Push Buttons (for configuration and navigation). Electrical Supply Voltage 10.5 to 45 V DC (Two-wire). Load Limit R_L ≤ (Vs - 10.5V) / 0.022 A (Ω). Communication HART Protocol (Bell 202 FSK). Process Connections & Materials Wetted Parts (BSH) Isolating Diaphragms & Process Connections: 316L Stainless Steel (Standard). Fill Fluid Silicone Oil (Standard) or Inert Fluorocarbon (for O2/aggressive service). Pressure Ports 1/4" NPT or G1/2" female (Common). Static Pressure Rating Up to 16 MPa (2320 psi). Mechanical & Environmental Housing Stainless Steel, Flameproof (Ex d) enclosure. Protection Degree IP66 / IP67 / NEMA 4X. Process Temperature -40°C to +120°C (Standard fill fluid). Ambient Temperature -40°C to +85°C. Certifications & Safety Explosion Protection (TB) ATEX / IECEx: Ex d IIC T4/T6 Gb (Flameproof) & Ex ia IIC T4/T6 Ga (Intrinsic Safety) - Dual Certification. Functional Safety SIL 2/3 capable.

Parameters Category Parameter Specification / Interpretation for 266DSHBSHA1B2 V1L1B1TB General Model Series 2600T Series (DST - Differential Pressure Smart Transmitter) Type Smart dP Transmitter with Steam Flow Option & Local Display Output 4-20 mA DC, Two-wire, HART Protocol. Measurement & Computation Primary Measurement Differential Pressure (dP) Calibrated dP Span (BSHA1) Defined by core code. Example: 0 to 100 kPa (1 bar). Must verify from datasheet. Reference Accuracy (dP) ±0.075% of calibrated span (Typical). Steam Flow Option (V1) On-board IAPWS-IF97 steam properties. Output can be configured as Mass Flow Rate (e.g., kg/h, lb/h). Output Characterization (B1) Selectable: Linear (for pressure/level) or Square Root (for flow with primary element). With V1, output is linearized flow. Options & Features Local Display (L1) LCD Local Indicator. Certification Package (TB) ATEX / IECEx: Ex d IIC T4/T6 Gb (Flameproof) & Ex ia IIC T4/T6 Ga (Intrinsic Safety) certificates. Electrical Supply Voltage 10.5 to 45 V DC (Two-wire). Communication HART Protocol. Process Connections & Materials Wetted Parts (BSH) Isolating Diaphragms: 316L SST or similar alloy. Fill Fluid Silicone Oil or Inert Fluorocarbon. Pressure Ports 1/4" NPT or G1/2" female. Mechanical & Environmental Housing Stainless Steel, Flameproof. Protection Degree IP66 / IP67 / NEMA 4X. Process Temperature -40°C to +120°C. Ambient Temperature -40°C to +85°C.

Parameters Category Parameter Specification / Interpretation for 266HDHHRMA7+LSTB General Model Series 2600T Series (PGT - Pressure Gauge/Absolute Transmitter) Type Smart Absolute Pressure Transmitter with Local Operator Interface Output 4-20 mA DC, Two-wire, HART 7 Digital. Measurement Performance Measured Variable Absolute Pressure Calibrated Span (HDHHRMA7) Defined by core code. Example: 0 to 400 kPa abs (4 bar abs). Must be verified from official datasheet. Reference Accuracy ±0.055% to ±0.075% of calibrated span (Typical for this performance grade). Long-Term Stability ±0.1% of URL per year. Options & Features (+LSTB) Local Operator Interface Backlit Graphical LCD Display. Infrared (IR) Push Buttons (for Ex ia certified local operation). Certification Package ATEX / IECEx: Ex d IIC T6 Gb (Flameproof) & Ex ia IIC T6 Ga (Intrinsic Safety) - Dual Certification. Electrical Supply Voltage 10.5 to 45 V DC (Two-wire). Communication HART 7 Protocol. Process Connections & Materials Process Connection 1/2" NPT female or G1/2" (typical). Wetted Parts 316L Stainless Steel (standard). Other alloys (Hastelloy, Monel) available with different suffix. Mechanical & Environmental Housing Stainless Steel, Flameproof (Ex d) enclosure. Protection Degree IP66 / IP67 / NEMA 4X. Process Temperature -40°C to +120°C (standard fill fluid). Ambient Temperature -40°C to +85°C.

Parameters Category Parameter Specification / Interpretation for 266HSHQKBA7 General Model Series 2600T Series (FMT - Flow Multivariable Transmitter) Type Smart Multi-Variable Flow Transmitter with Corrosion-Resistant Wetted Parts Measured Variables Differential Pressure (ΔP), Static Pressure (Ps), Temperature (T). Measurement Performance ΔP Span Range Defined by suffix "QKBA7". Indicates a specific calibrated span. Example: 0 to 100 kPa (1 bar). Must verify from datasheet. Static Pressure (Ps) Range High Range, e.g., 0 to 16 MPa (2320 psi). Temperature (T) Range Integrated RTD: -40°C to +125°C. Reference Accuracy (Flow) ±0.15% of reading (typical for compensated flow). Long-Term Stability ±0.1% of URL per year. Computation & Output Calculated Variable Mass Flow or Volumetric Flow (density-compensated). Fluid Database Pre-loaded with common gas & steam properties. Primary Element Support Orifice, Venturi, Nozzle, Wedge, Pitot Tube (per ISO/AGA). Analog Output 4-20 mA, two-wire. Primary Variable = Flow. Digital Output HART 7 Protocol. Process Connections & Materials (Key Feature) Wetted Parts (QK) Isolating Diaphragms: Hastelloy C-276 or equivalent nickel-based alloy. Process Flanges/Connections: 316L SST or matching alloy. Fill Fluid Silicone oil or Inert Fluorocarbon (specify for O2 service). Pressure Ports 1/4" NPT or G1/2" female (typically in 316L SST). Mechanical & Environmental Housing Stainless Steel. Protection Degree IP66 / IP67 / NEMA 4X. Process Temperature -40°C to +120°C (wetted parts). Ambient Temperature -40°C to +85°C. Certifications Explosion Protection Base design supports ATEX/IECEx: Ex ia IIC T4/T6 Ga & Ex d IIC T4/T6 Gb (as an ordered option). Material Certs 3.1 Material Certificate typically provided for the Hastelloy wetted parts.

Parameters Category Parameter Specification / Interpretation for 266HSHMSBA7 General Model Series 2600T Series (FMT - Flow Multivariable Transmitter) Type Smart Multi-Variable Flow Transmitter (4-20mA HART 7) Measured Variables Differential Pressure (ΔP), Static Pressure (Ps), Temperature (T). Measurement Performance ΔP Span Range Defined by suffix "MSBA7". Indicates a specific calibrated span. Example: 0 to 25 kPa (0.25 bar). Must verify from datasheet. Static Pressure (Ps) Range High Range, e.g., 0 to 16 MPa (2320 psi). Temperature (T) Range Integrated RTD: -40°C to +125°C. Reference Accuracy (Flow) ±0.15% of reading (typical for density-compensated flow). Long-Term Stability ±0.1% of URL per year. Computation & Output Calculated Variable Mass Flow or Volumetric Flow (density-compensated). Fluid Database Pre-loaded with common gas & steam properties. Primary Element Support Orifice, Venturi, Nozzle, Wedge, Pitot Tube (per ISO/AGA). Analog Output 4-20 mA, two-wire. Primary Variable = Flow. Digital Output HART 7 Protocol. Electrical Supply Voltage 10.5 to 42 V DC (Two-wire loop). Communication HART 7 (Bell 202 FSK). Process Connections & Materials ΔP Ports 1/4" NPT or G1/2" female. Ps & T Port Integrated, with 1/2" NPT process connection. Wetted Parts (MSB) Suffix "MSB" indicates materials: Likely standard 316L SST isolating diaphragms and process connections. Mechanical & Environmental Housing Stainless Steel. Protection Degree IP66 / IP67 / NEMA 4X. Process Temperature -40°C to +120°C (wetted parts). Ambient Temperature -40°C to +85°C. Certifications Explosion Protection Base design supports ATEX/IECEx: Ex ia IIC T4/T6 Ga & Ex d IIC T4/T6 Gb (as an ordered option). Safety Integrity SIL 2/3 capable.

Parameters Category Parameter Specification / Interpretation for 266DSH FSSAIA7/EY/LS/TB General Model Series 2600T Series (DST - Differential Pressure Smart Transmitter) Type Smart dP Transmitter with Remote Diaphragm Seals & Local Interface Output 4-20 mA DC, Two-wire, HART 7 Digital. Measurement Performance Measured Variable Differential Pressure (dP) Calibrated Span (FSSAIA7) Defined by core code. Example: 0 to 40 kPa (0.4 bar). Must be verified from datasheet. Reference Accuracy ±0.055% to ±0.075% of calibrated span (Typical for this grade). Long-Term Stability ±0.1% of URL per year. Options & Features Remote Diaphragm Seals (/EY) Material: 316L SST, Hastelloy, Tantalum, etc. (Specified separately). Capillary Length: Custom (e.g., 1m, 3m, 5m). Fill Fluid: Silicone oil, Inert fluid (matched to process temp.). Local Operator Interface (/LS) Graphical LCD Display. Infrared Push Buttons for Ex ia certified local operation. Certification Package (/TB) ATEX / IECEx: Ex d IIC T6 Gb (Flameproof) & Ex ia IIC T6 Ga (Intrinsic Safety) certificates. May include SIL documentation. Electrical Supply Voltage 10.5 to 45 V DC (Two-wire). Communication HART 7 Protocol. Process Connection (via Seals) Seal Process Connection Flanged (e.g., DIN, ANSI, JIS) or Threaded (e.g., 1/2" NPT). Defined with /EY order. Transmitter Pressure Ports For capillary connection (e.g., 1/4" NPT). Mechanical & Environmental Transmitter Housing Stainless Steel, Flameproof (Ex d) enclosure. Protection Degree IP66 / IP67 / NEMA 4X. Ambient Temperature (Tx) -40°C to +85°C. Process Temperature (Seals) Depends on seal fill fluid. Can exceed +400°C with appropriate seals/fluid.