PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

EPRO

Key Features: 204.8kHz/channel sampling (24-bit resolution) 150dB dynamic range for superior signal fidelity 16-64 channel modular architecture AI-powered fault detection (bearings, gears, imbalance) Triple-redundant power with supercapacitor backup 5G/Wi-Fi 6E wireless connectivity options Technical Highlights: 0.01-100,000 RPM speed measurement (0.005% accuracy) 65,536-line FFT for ultra-fine spectral analysis 32 SIL 3-rated relays (250VAC/10A) -40°C to +85°C operation with IP66/IP69K protection IEC 62443-3-3 cybersecurity compliance Monitoring Capabilities: Shaft/casing vibration (up to 3000µm pk-pk) Thrust position (±10mm) & eccentricity 16 process parameter inputs (4-20mA/RTD/TC) Torsional vibration (optional) System Benefits: Predictive maintenance with digital twin integration Sub-millisecond response for critical protection Future-proof architecture supports TSN/EtherCAT G10 Blockchain-secured data logging 10-year lifecycle guarantee Certifications: API 670 (4th Ed.), ISO 7919/10816 ATEX Zone 0, SIL 3, Nuclear 1E (options) CE, UL, IECEx Typical Applications: 1000MW+ steam turbines Offshore compressor trains Nuclear reactor coolant pumps High-speed centrifugal compressors Smart factory installations Next-Generation Features: Quantum-resistant encryption (optional) Edge AI co-processor for real-time analytics ANSYS/MATLAB digital twin interface

644

EPRO

Key Features: 8mm high-temperature probe with Inconel 718 housing Wide measuring range (0.5-3.0mm) with 8mV/µm sensitivity Exceptional temperature resistance (-50°C to +250°C continuous, +300°C short-term) IP68 submersible rating and 200 bar pressure capability MIL-spec connector for secure signal transmission Technical Specifications: Frequency response: 0-15kHz (±3dB) Power supply: -18 to -24VDC Output signal: -2 to -22VDC Double-sealed construction (graphite/Viton®) M10×1 threaded mounting Performance Highlights: ±1% linearity across full range Active temperature compensation (±0.03%/°C) 100g vibration resistance Mineral-insulated stainless steel cable included Typical Applications: Gas turbine hot gas path monitoring Nuclear power plant primary coolant pumps Geothermal energy systems Aerospace component testing High-pressure compressor trains Certifications & Compliance: Meets API 670 and ISO 7919 requirements ATEX/IECEx versions available CE and SIL 2 compliant Installation Notes: Requires AISI 4140/4340 steel targets NIST-traceable calibration provided Special mounting procedures for >250°C applications This system is specifically designed for critical monitoring in power generation, oil & gas, and aerospace applications where conventional sensors would fail. Its robust construction ensures long-term reliability in extreme temperature and pressure conditions.

91

EPRO

Key Features ✔ Multi-Parameter Monitoring – Tracks vibration, position, speed, and process variables (6–18 channels, expandable) ✔ Ultra-High Resolution – 102.4 kHz sampling rate per channel with 140 dB dynamic range ✔ Industrial-Grade Processing – Quad-core CPU, 16GB RAM, 256GB SSD for real-time analytics ✔ Flexible Sensor Support – Works with eddy current probes, velocity sensors, accelerometers, and keyphasors ✔ Advanced Protection – 24 SIL-rated relays, configurable trip logic (2oo3, 2oo4 voting) ✔ Cybersecurity Ready – IEC 62443-3-3 compliant with OPC UA, PROFINET, EtherCAT Technical Highlights Real-time FFT (40,000 lines) + orbit analysis Automated fault detection (bearing, gear mesh, imbalance) -40°C to +75°C operation, IP66/IP67 protection Dual-redundant power supply (88–300VAC or 18–36VDC) Cloud & AI integration (SAP, Predix, EPRO CortexAI) Applications Gas/steam turbines Centrifugal compressors Critical pumps & motors Offshore/platform machinery Certifications API 670 (4th Ed.), ISO 7919/10816 ATEX/IECEx Zone 1 (optional) SIL 2 (optional), CE, UL The MMS6310 sets a new benchmark in machinery health monitoring, offering unmatched precision, reliability, and connectivity for Industry 4.0 applications.

527

EPRO

Key Features: 12-channel base configuration (expandable to 32 channels) High-speed 51.2kHz sampling per channel 130dB dynamic range for precise measurements Supports all EPRO sensor types (eddy current, velocity, acceleration) Advanced diagnostic capabilities including real-time FFT and orbit plots Technical Specifications: Dual-core industrial processor with 8GB RAM Multiple communication protocols (Modbus, OPC UA, PROFIBUS, Ethernet/IP) 16 configurable relay outputs (250VAC/5A) Wide operating temperature range (-40°C to +70°C) IP66 front panel protection Monitoring Capabilities: Shaft vibration (radial and axial) Casing vibration (velocity/acceleration) Position (thrust, eccentricity) Speed measurement (RPM) Process variables (4-20mA inputs) Safety & Protection: Programmable voting logic (1oo2, 2oo3, etc.) 4 alarm setpoints per channel SIL 2 compliant version available Optional ATEX/IECEx certification Typical Applications: Power generation turbines Oil & gas compressors Critical pump trains Large motor monitoring Integrated plant protection systems System Benefits: Early fault detection through continuous monitoring Reduced downtime with predictive maintenance Enhanced safety with redundant protection Flexible integration with control systems Rugged design for harsh environments Certifications: Complies with API 670, ISO 7919, ISO 10816 CE marked Optional SIL 2 and ATEX certifications The MMS3120 represents EPRO's latest generation of machinery protection systems, combining decades of field experience with cutting-edge monitoring technology for the most demanding industrial applications.

639

EPRO

Key Features: High-accuracy speed monitoring (1-30,000 RPM range) Dual programmable setpoints (overspeed/underspeed) 5-digit LED display with 0.1 RPM resolution Multiple input options (MPU or proximity probe) Self-diagnostics and sensor health monitoring Technical Specifications: Measurement accuracy: ±0.1% of reading 3 SPDT relay outputs (250VAC/5A) Wide power supply range (24VDC or 85-264VAC) Communication: RS-485 Modbus RTU Operating temperature: -30°C to +70°C Protection Capabilities: Adjustable trip delays (0.1-10 seconds) Failsafe relay configuration Programmable pulses/revolution (1-60) Optional dual-sensor redundancy Typical Applications: Steam and gas turbine protection Compressor train monitoring Critical pump/motor speed control Integration with safety shutdown systems Certifications: Complies with API 670 ATEX/IECEx versions available CE and UL listed Optional SIL 2 compliance Installation: Panel-mounted design (96×96mm) IP65 front protection Aluminum alloy housing The UES 815S is engineered for demanding industrial environments, providing reliable speed protection for power generation, oil & gas, and heavy industrial applications. Its combination of precision measurement and robust safety features makes it ideal for critical machinery protection systems.

273

EPRO

Key Features: Dual-channel design for simultaneous signal processing Universal compatibility with EPRO eddy current and velocity sensors Advanced noise filtering (DC-15kHz bandwidth) 250VAC channel-to-channel isolation MIL-spec threaded connectors for secure connections Technical Specifications: Input Types: Accepts 8mm/11mm proximity probes & 4-20mA velocity sensors Environmental Rating: IP65 enclosure (-40°C to +85°C operation) Cable Support: 500m maximum with shielded cabling Mounting Options: DIN rail or panel mount Compliance: IEC 61000 EMC, RoHS Typical Applications: Power plant turbine monitoring systems Compressor protection installations Critical pump vibration monitoring Retrofit projects for legacy monitoring systems Benefits: Ensures signal integrity in electrically noisy environments Simplifies system integration with standardized connections Reduces false alarms through effective signal conditioning Provides reliable performance in harsh industrial conditions

634

EPRO

Key Features: ✔ 5mm/8mm Probe Options – Flexible sizing for different measurement needs ✔ Wide Measuring Range – 0.25–2.5mm (adjustable) with 7.87 mV/µm sensitivity ✔ High-Frequency Response – 0–15 kHz (±3 dB) for dynamic vibration monitoring ✔ Extreme Environment Rated – IP68 submersible, operates at -40°C to +175°C ✔ Robust Construction – Titanium alloy housing for corrosion resistance ✔ Long-Distance Signal Integrity – Supports up to 1,000m cable runs Applications: Turbomachinery (turbines, compressors, pumps) Aerospace & marine propulsion systems High-speed spindles & precision rotating equipment Hydroelectric generator monitoring Certifications & Compliance: API 670, ISO 7919 compliant ATEX/IECEx versions available (hazardous area use) CE & RoHS certified

961

EPRO

Core Features: 8mm stainless steel probe with M10×1 threading 0.5-2.5mm measuring range (8mV/µm sensitivity) Wide frequency response (DC to 10kHz) Military-grade connector for reliable signal transmission IP67 protection rating for harsh environments Technical Highlights: Operating temperature range: -40°C to +150°C -24VDC power supply with 50Ω output impedance ±1% linearity across full measurement range Supports cable runs up to 500 meters Typical Applications: Turbine and compressor shaft monitoring Bearing condition assessment Rotor position and eccentricity measurement Speed sensing in critical machinery Certifications & Compliance: Meets API 670 and ISO 7919 standards ATEX/IECEx versions available CE and RoHS compliant This system is particularly suited for power generation, oil & gas, and heavy industrial applications where reliable machinery protection is essential. Its robust construction ensures accurate measurements even in challenging operating conditions.

274

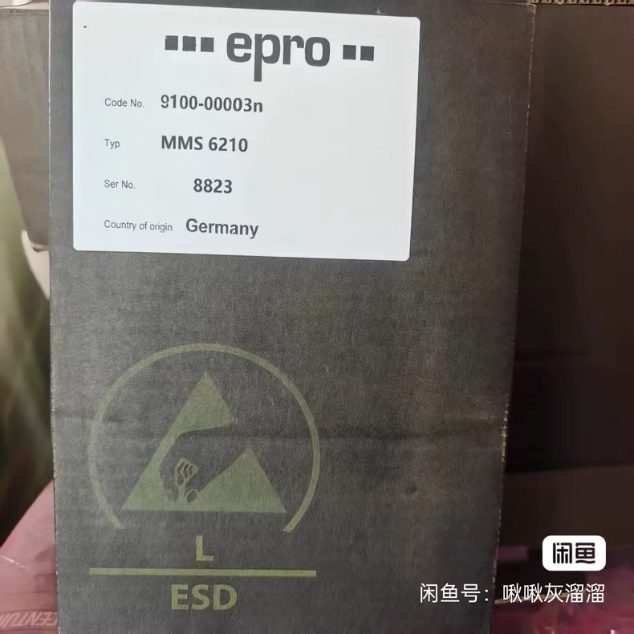

EPRO

Key Features: Multi-parameter monitoring (6-12 channels, expandable) Supports all EPRO sensor types (eddy current, velocity, accelerometers) High-speed data acquisition (25.6kHz/channel) Advanced diagnostic capabilities with waveform/spectrum analysis Flexible communication interfaces (Modbus, PROFIBUS, Ethernet) Web-based configuration and monitoring Technical Specifications: Compliant with API 670, ISO 7919 and ISO 10816 standards Wide measurement ranges for vibration, position and speed Configurable alarm setpoints with dynamic adaptation 85-264VAC or 24VDC power supply options Operating temperature range: -30°C to +70°C Typical Applications: Power generation turbines Oil & gas compressors Critical pumps and motors Rotating machinery in hazardous areas (ATEX option) System Benefits: Early fault detection through continuous monitoring Reduced downtime with predictive maintenance Flexible integration with control systems Rugged design for harsh environments The MMS6210 combines EPRO's proven reliability with advanced monitoring technology, making it ideal for protecting high-value assets in demanding industrial environments.

481

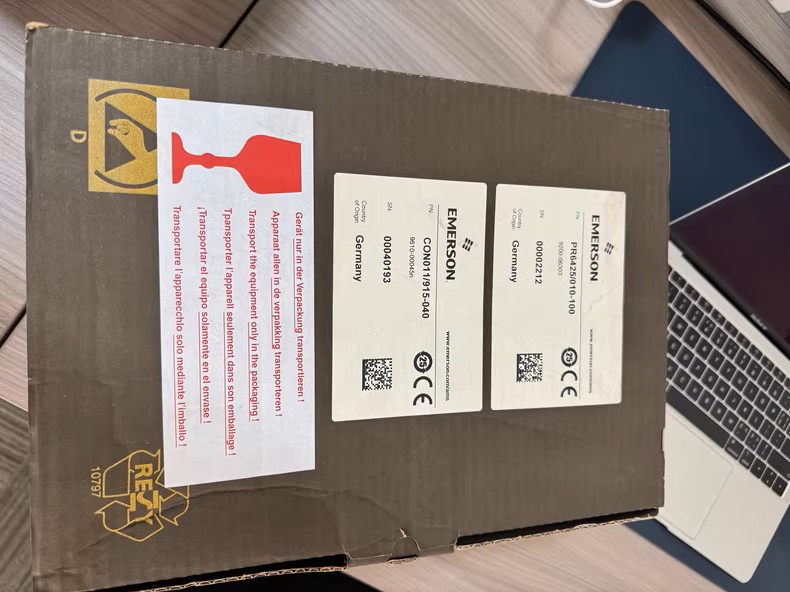

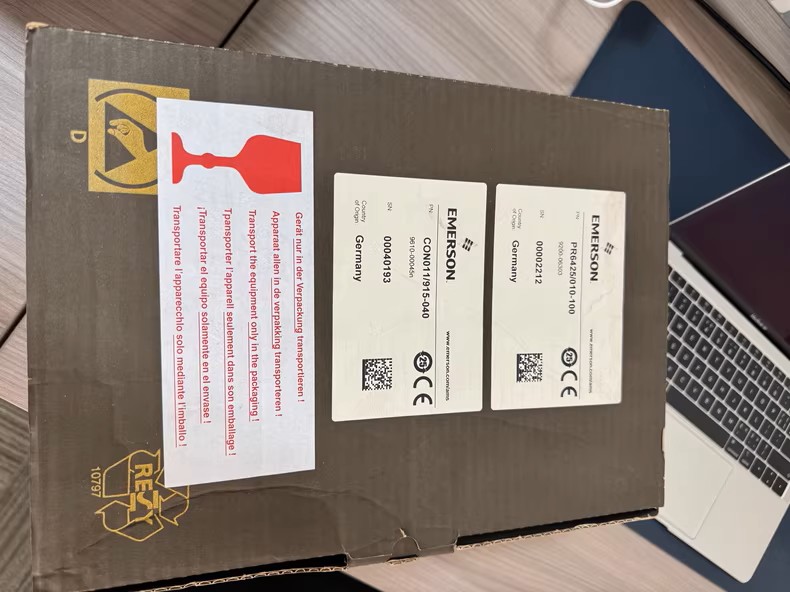

EPRO

Key Features: 8mm diameter probe with stainless steel construction Wide measuring range (0.5-2.5mm) with 8mV/µm sensitivity Excellent frequency response (0-10kHz) High temperature operation (-40°C to +150°C) IP67 protection rating for harsh environments ATEX/IECEx certified versions available Technical Specifications: Power supply: -24VDC ±10% Output signals: -2 to -18VDC (gap voltage), -4 to -20VDC (vibration) Military-style threaded connector Supports cable lengths up to 500m Typical Applications: Rotating machinery vibration monitoring Turbine and compressor protection systems Shaft position and eccentricity measurement Speed measurement applications Compliance & Standards: Meets API 670 and ISO 7919 requirements Optional hazardous area certifications available The PR6425/010-100 system offers exceptional reliability and accuracy for predictive maintenance programs in power generation, oil & gas, and other heavy industries. Its robust design ensures long-term performance in critical monitoring applications.

301

EPRO

Key Features: Signal conditioning for eddy current probes and velocity sensors Galvanic isolation between channels (250VAC) Wide frequency response (DC to 15kHz) DIN rail or panel mounting options IP65-rated enclosure for harsh environments Technical Highlights: Screw terminal connections for secure wiring Built-in noise filtering for signal integrity Supports cable runs up to 500 meters Wide operating temperature range (-40°C to +85°C) Typical Applications: Integration with EPRO 9000 series monitors Turbine and compressor monitoring systems Industrial machinery protection installations Vibration measurement signal conditioning Compliance: Meets IEC 61000 EMC standards RoHS compliant Optional ATEX/IECEx versions available

109

EPRO

Key Features: Dual-channel design for simultaneous monitoring of two measurement points Supports multiple sensor types (eddy current probes, velocity sensors, and accelerometers) Wide measurement range (0-500µm vibration, 0-50mm/s velocity) Advanced signal processing with 10kHz sampling rate Configurable alarm setpoints with delay timers Multiple output options (4-20mA, ±10V, RS-485/Modbus) Technical Specifications: Compliant with API 670 and ISO 7919 standards IP66/IP67 rated enclosure for harsh environments Wide operating temperature range (-30°C to +70°C) 24VDC or 100-240VAC power supply options ATEX/IECEx certified versions available Typical Applications: Turbines and compressors in power generation Critical pumps and motors in oil & gas Rotating machinery in chemical plants Predictive maintenance systems Benefits: Enhanced machinery protection Reduced downtime through early fault detection Flexible integration with control systems Reliable operation in extreme conditions

889