PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

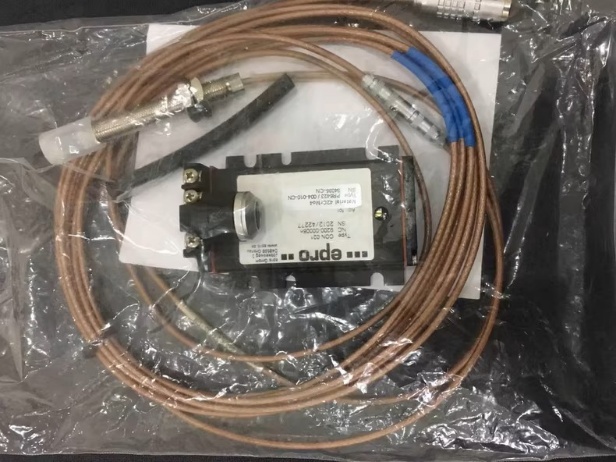

EPRO

Key Features: Range: 0-10mm | Sensitivity: -8.0V/mm Output: -2 to -18V DC (linear to gap) Frequency Response: 0-10kHz Robust Design: 316SS housing, IP67 protection Temp Range: -30°C to +120°C (180°C with HT cable) Applications: ✓ Shaft vibration monitoring ✓ Rotor position measurement ✓ Bearing condition analysis Compatibility: EPRO MMS6000 systems

246

EPRO

Key Features: ✔ Wide Range: 0–10 mm measurement ✔ High Sensitivity: –0.8 V/mm (optimized for steel targets) ✔ Fast Response: 0–10 kHz frequency range ✔ Robust Build: Stainless steel housing, IP67 protection ✔ Extreme Temp: Operates from –30°C to +120°C (up to 180°C with HT cable) Applications: Turbine/compressor shaft vibration monitoring Rotor position and axial displacement measurement Bearing condition analysis in critical machinery (Compatible with EPRO MMS6000 systems. Requires proper gap calibration.)

56

EPRO

Key Features: Measurement Range: 0-3.0mm Sensitivity: -7.87V/mm (optimized for steel) Output: -2 to -18V DC (linear to gap) Frequency Response: 0-10kHz Robust Design: 316 stainless steel, IP67 rated Temp Range: -30°C to +120°C (extendable to +180°C) Applications: ✓ Turbine/compressor shaft vibration ✓ Rotor position monitoring ✓ Bearing condition analysis Compatible with EPRO MMS6000 systems. Requires proper gap calibration.

35

EPRO

Key Features: ✔ Range: 0–3.0 mm (non-contact measurement) ✔ Sensitivity: –7.87 V/mm (optimized for steel targets) ✔ Output: –2 to –18 V DC (linear to gap distance) ✔ Robust Build: 316 stainless steel, IP67 protection ✔ Temp Range: –30°C to +120°C (up to +180°C with HT cable) ✔ Frequency Response: 0–10 kHz (ideal for dynamic vibration) Applications: Turbine/compressor shaft vibration monitoring Rotor position and bearing health tracking Critical machinery protection systems

32

EPRO

Key Features: Measurement Range: 0–10 mm (factory calibrated) Output: –2 to –18 V DC (linear to gap distance) Sensitivity: –8.0 V/mm (optimized for steel targets) Robust Design: Stainless steel housing, IP67 protection Temperature Range: –30°C to +120°C (up to +180°C with HT cable) Compatibility: Works with EPRO MMS6000 monitoring systems Applications: Turbines, compressors, pumps, and critical rotating equipment requiring shaft vibration, radial/axial position, and rotor dynamics monitoring.

188

EPRO

Key Features: Measurement Range: ±50 g (±500 m/s²) Wide Frequency Response: 0.5 Hz – 10 kHz Output: 4–20 mA (loop-powered) or voltage signal Extreme Durability: Stainless steel housing, IP67 rated Operating Temp: -40°C to +120°C (higher with cooling option) Flexible Mounting: Threaded stud or magnetic base Applications: Pumps, motors, fans & compressors in power, oil/gas & heavy industries.

416

EPRO

Key Features: Input: Accepts signals from inductive sensors or proximity probes (0.5 Hz–15 kHz). Speed Range: Configurable up to 30,000 RPM with adjustable pulses/revolution. Outputs: Relay alarms/trips (SPDT) + 4–20 mA / 0–10 V analog output. High Accuracy: ±0.1% deviation for precise speed control. Robust Design: Supports 24V DC or 110/230V AC, operates in -20°C to +70°C. Safety Certifications: ATEX, SIL (optional for hazardous areas). Applications: Turbines, compressors, pumps, and gearboxes requiring overspeed protection.

620

EPRO

Key Features: Measurement Range: 0–4 mm (typical) Output: –2 to –18 V DC (proportional to gap distance) Sensitivity: –7.87 V/mm Robust Design: Operates in harsh conditions (up to 120°C) Compatibility: Integrates with EPRO MMS6000 and other monitoring systems Applications: Turbines, compressors, pumps, and rotating equipment protection.

373

EPRO

Key Features: Eddy Current Principle: Measures distance between the sensor tip and conductive targets. Operating Range: Typically 0–10 mm (adjustable based on setup). Output: Analog signal (e.g., –2 to –18 VDC proportional to gap distance). Robust Design: Suitable for harsh environments (high temps, oil, steam). Compatibility: Works with EPRO monitoring systems (e.g., MMS6000).

276

EPRO

Purpose: Ultra-sensitive high-temperature displacement sensor for precision monitoring in extreme environments. Key Features: 20.0 mV/µm sensitivity (0-0.5mm range) High-temp operation: -40°C to +200°C (peak 250°C) Ruggedized design: ✓ 20g vibration resistance ✓ 4MPa pressure rating ✓ M10×1 threaded probe Applications: ✔ Gas turbine blade clearance ✔ Nuclear pump monitoring ✔ Precision machinery in high heat Requirements: • Mineral-insulated cable (>105°C) • Signal conditioner recommended Compliance: API 670, ASME B31.1

262

EPRO

Core Function: High-temperature eddy current sensor for extreme environment displacement monitoring. Key Features: • Sensitivity: 8.0 mV/µm (±5%) • Range: 0-1.0mm (1000µm) • Temp Rating: -40°C to +200°C (peak 250°C) • Frequency Response: DC to 10kHz Robust Design: ✓ 8mm high-temp probe ✓ M10×1 threaded mount ✓ 20g vibration resistance ✓ 4MPa pressure rating Applications: Gas turbine hot sections Steam turbine monitoring High-temp industrial equipment Compliance: API 670

666

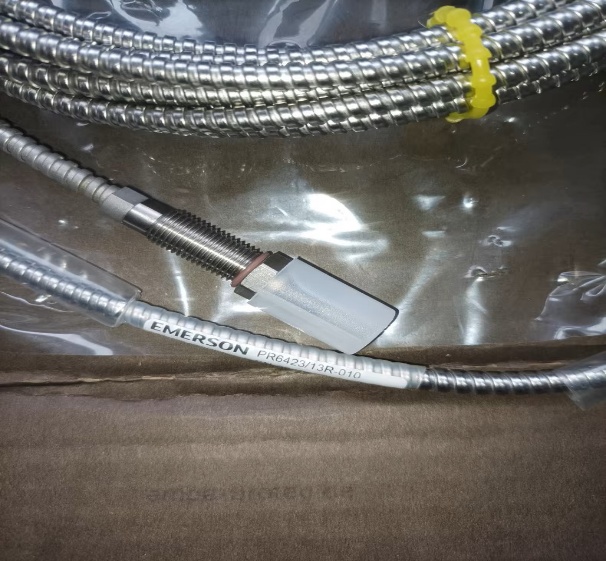

EPRO

Purpose: Heavy-duty eddy current sensor for vibration/displacement monitoring in extreme industrial environments. Key Features: 8.0 mV/µm sensitivity (0-1.0mm range) Ruggedized /13R design: ✓ IP68 protection ✓ 25g vibration resistance ✓ 6MPa pressure rating Wide temp range: -40°C to +150°C Applications: ✔ Offshore compressors ✔ Mining equipment ✔ High-vibration machinery Compliance: API 670 Options: ATEX/IECEx versions available

676