PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

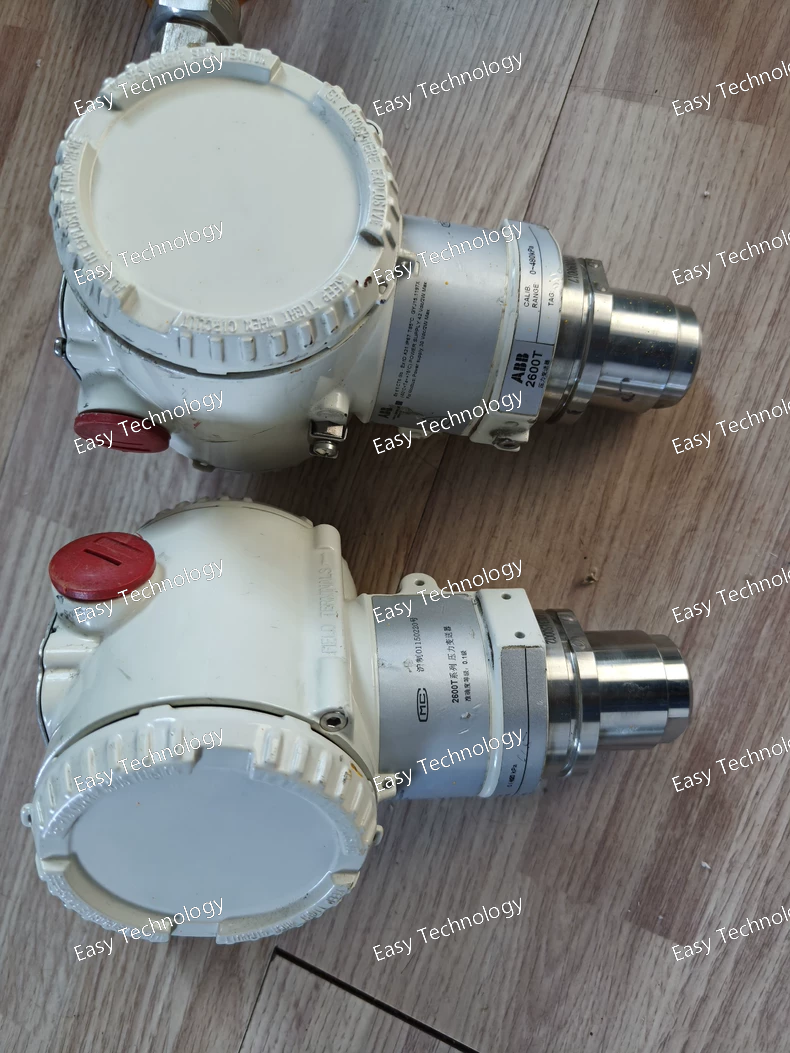

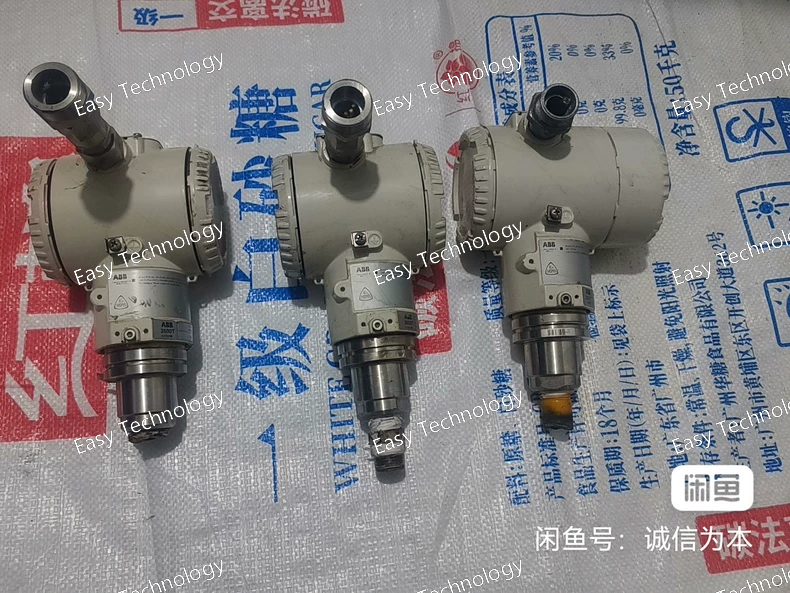

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 HSH (High Static Pressure) Output: 4–20 mA two-wire with HART communication Sensor Technology: Digital capacitive sensor with temperature compensation Measurement Performance Reference Accuracy: ±0.04% of span Repeatability: ±0.02% of span Turn-Down Ratio: Up to 100:1 Response Time: <100 ms Long-Term Stability: ±0.1% of URL over 10 years Pressure Ratings Differential Pressure Range: According to SBA1 sensor selection Static Pressure Rating: Up to 105 MPa (high-static HRH/HSH variant) Proof Pressure: 1.5 × static rating Overpressure Protection: Integrated mechanical system Materials & Construction Wetted Materials: Stainless steel / Hastelloy / optional alloys (per SBA1 selection) Fill Fluid: Silicone or inert fluid Housing: Aluminum or stainless steel (depending on configuration) Process Connections: High-pressure flanges or threaded adapters Electrical & Communication Power Supply: 10.5–45 VDC Output Signal: 4–20 mA + HART digital Load Resistance (HART): ≤600 Ω Local Configuration: Optional push-button or LCD interface Environmental Conditions Electronics Operating Temperature: –40 to +85 °C Process Temperature: According to sensor and fill fluid Humidity: 0–100% RH, non-condensing Ingress Protection: IP67 / IP68 depending on housing and terminals Vibration Resistance: Up to 10 g, 10–2000 Hz Certifications / Standards Explosion Protection: Ex ia / Ex d / Ex nA (depending on configuration) Compliance: ATEX, IECEx, PED, CE EMC & Surge Protection: Industrial-grade standards

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 HRH (High Pressure Differential) Output: 4–20 mA two-wire with HART communication Sensor Technology: Digital capacitive sensor with temperature compensation Measurement Performance Reference Accuracy: ±0.04% of span Repeatability: ±0.02% of span Turn-Down Ratio: Up to 100:1 Response Time: <100 ms Long-Term Stability: ±0.1% of URL over 10 years Pressure Ratings Differential Pressure Range: Configurable per PRRA7 sensor selection Static Pressure Rating: Up to 105 MPa (high-pressure HRH variant) Proof Pressure: 1.5 × static rating Overpressure Protection: Integrated mechanical system Materials & Construction Wetted Materials: Stainless steel / Hastelloy / optional alloys (per PRRA7 selection) Fill Fluid: Silicone oil or inert fluid Housing: Aluminum or stainless steel (B7TB configuration) Process Connections: High-pressure flanges or threaded adapters Electrical & Communication Power Supply: 10.5–45 VDC Output Signal: 4–20 mA + HART digital Load Resistance (HART): ≤600 Ω Local Configuration: Push-button or LCD interface (if equipped) Environmental Conditions Electronics Operating Temperature: –40 to +85 °C Process Temperature: According to sensor and fill fluid selection Humidity: 0–100% RH, non-condensing Ingress Protection: IP67 / IP68 depending on housing and terminals Vibration Resistance: Up to 10 g, 10–2000 Hz Certifications / Standards Explosion Protection: Ex ia / Ex d / Ex nA (depending on configuration) Compliance: ATEX, IECEx, PED, CE EMC & Surge Protection: Industrial-grade standards

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 DSH (High Static Pressure) Output: 4–20 mA two-wire with HART communication Sensor Technology: Digital capacitive sensor with temperature compensation Measurement Performance Reference Accuracy: ±0.04% of span Repeatability: ±0.02% of span Turn-Down Ratio: Up to 100:1 Response Time: <100 ms Long-Term Stability: ±0.1% of URL over 10 years Pressure Ratings Differential Pressure Range: Configurable per SSA2B7 sensor selection Static Pressure Rating: Up to 41 MPa (DSH high-static variant) Proof Pressure: 1.5 × static rating Overpressure Protection: Integrated mechanical system Materials & Construction Wetted Materials: Stainless steel / Hastelloy / optional alloys (per SSA2B7 selection) Fill Fluid: Silicone or inert fluid Housing: Aluminum or stainless steel (EZLSB configuration) Process Connections: Flanges or threaded high-pressure adapters Electrical & Communication Power Supply: 10.5–45 VDC Output Signal: 4–20 mA + HART digital Load Resistance (HART): ≤600 Ω Local Configuration: Push-button or LCD interface (if equipped) Environmental Conditions Electronics Operating Temperature: –40 to +85 °C Process Temperature: According to sensor and fill fluid Humidity: 0–100% RH, non-condensing Ingress Protection: IP67 / IP68 depending on housing and terminals Vibration Resistance: 10 g, 10–2000 Hz Certifications / Standards Explosion Protection: Ex ia / Ex d / Ex nA (depending on configuration) Compliance: ATEX, IECEx, PED, CE EMC & Surge Protection: Industrial-grade standards

Specifications General Type: Electronic Protection Relay / Trip Unit Series: ABB S200 Series (S264) Application: Low-voltage switchgear and distribution protection Mounting: Panel or DIN rail mount Protection Functions Overcurrent Protection (Instantaneous and Time-Delayed): Configurable Short-Circuit Protection: Adjustable thresholds Earth-Fault Protection: Optional, configurable sensitivity Phase Failure / Imbalance Detection: Included Monitoring Functions: Voltage, current, active/reactive power, energy, frequency Electrical Characteristics Control Voltage: As per configuration (ES1 variant, typically 24–250 V AC/DC) Rated Current: Defined by S264 relay module Output Contacts: Trip and alarm contacts (normally open / normally closed) Communication Protocols: ABB standard communication (e.g., Modbus, PROFIBUS depending on option) Display: LCD with status indicators and menu navigation Environmental Conditions Operating Temperature: –25 to +70 °C Storage Temperature: –40 to +85 °C Humidity: 0–95% RH, non-condensing Shock & Vibration Resistance: IEC 60068 standard compliant Mechanical Housing Material: High-strength thermoplastic Ingress Protection: IP20 (panel-mounted), IP40 / IP54 options depending on enclosure Dimensions: Standard S200 relay size Certifications / Standards Standards Compliance: IEC/EN 60947-4-1, IEC/EN 60255, UL listed Safety & EMC: CE marked, IEC/EN EMC compliant

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 GSH Output: 4–20 mA, two-wire with HART communication Sensor Technology: Digital capacitive differential sensor with temperature compensation Measurement Performance Reference Accuracy: ±0.04% of span (depending on calibration and range) Repeatability: ±0.02% of span Turn-Down Ratio: Up to 100:1 Response Time: <100 ms Long-Term Stability: ±0.1% URL over 10 years Pressure Ratings Differential Pressure Range: According to CKBNA1 sensor selection Static Pressure Rating: High static pressure capability (per GSH design) Proof Pressure: 1.5 × static rating Overpressure Protection: Integrated mechanical system Materials & Construction Wetted Parts: Stainless steel / Hastelloy / optional alloys (per CKBNA1) Fill Fluid: Silicone oil or inert fluid Housing: Aluminum or stainless steel (per model configuration) Process Connections: Flanges or threaded high-pressure adapters Electrical & Communication Power Supply: 10.5–45 VDC Signal: 4–20 mA + HART digital Load Resistance (HART): ≤600 Ω Local Configuration: Optional push-button or LCD interface Environmental Conditions Electronics Operating Temperature: –40 to +85 °C Process Temperature: Based on sensor and fill fluid Humidity: 0–100% RH, non-condensing Ingress Protection: IP67 / IP68 depending on housing and electrical entry Vibration Resistance: Up to 10 g, 10–2000 Hz Certifications / Compliance Explosion Protection: Ex ia / Ex d / Ex nA options depending on configuration Compliance: ATEX, IECEx, PED, CE EMC / Surge Protection: Industrial-grade standards

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 HSH (High Static Pressure) Output: 4–20 mA, two-wire with HART communication Sensor Technology: Digital capacitive sensor with temperature compensation Measurement Performance Reference Accuracy: ±0.04% of span (depending on range) Repeatability: ±0.02% of span Turn-Down Ratio: Up to 100:1 Response Time: <100 ms (configurable damping available) Long-Term Stability: ±0.1% of URL over 10 years Pressure Ratings Differential Pressure Range: As per MSBA1 sensor selection Static Pressure Rating: Up to 105 MPa (1050 bar) Proof Pressure: 1.5 × static rating Overpressure Protection: Integrated mechanical overload system Materials & Construction Wetted Materials: Stainless steel / Hastelloy / optional alloys (per MSBA1 selection) Fill Fluid: Silicone or inert fluid Housing: Aluminum or stainless steel (EZTB configuration) Process Connections: High-pressure flanges or threaded adapters Electrical & Communication Power Supply: 10.5–45 VDC Output Signal: 4–20 mA + HART Load Resistance (HART): ≤600 Ω Local Configuration: Optional push-button or LCD interface Environmental Conditions Electronics Operating Temperature: –40 to +85 °C Process Temperature: According to fill fluid and sensor materials Humidity: 0–100% RH, non-condensing Ingress Protection: IP67 / IP68 depending on housing selection Vibration Resistance: 10 g, 10–2000 Hz Certifications / Compliance Explosion Protection: Ex ia / Ex d / Ex nA (per configuration) Standards Compliance: ATEX, IECEx, PED, CE EMC / Surge Protection: Industrial-grade standards

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 HSH (High Static Pressure) Output: 4–20 mA, two-wire with HART protocol Sensor Type: Digital capacitive sensor with temperature compensation Measurement Performance Reference Accuracy: ±0.04% of span (depending on range) Repeatability: ±0.02% of span Turn-Down Ratio: Up to 100:1 Response Time: <100 ms (depending on damping) Long-Term Stability: ±0.1% URL over 10 years Pressure Ratings Differential Pressure Range: According to PSBB7 sensor module selection Static Pressure Limit: Up to 105 MPa (1050 bar) Proof Pressure: 1.5 × static rating Overpressure Protection: Integrated mechanical system Materials & Construction Wetted Materials: Stainless steel, Hastelloy, or optional alloys per PSBB7 code Fill Fluid: Silicone oil or inert fluid Housing: Aluminum or stainless steel (as defined by L9TB) Process Connections: High-pressure flanges or threaded adapters Electrical & Communication Power Supply: 10.5–45 VDC Signal: 4–20 mA + HART digital Load Resistance (HART): ≤600 Ω Local Configuration: Push-button or optional LCD interface Environmental Conditions Electronics Operating Temperature: –40 to +85 °C Process Temperature: Dependent on sensor and fill fluid Humidity: 0–100% RH, non-condensing Ingress Protection: IP67 / IP68 (depending on housing selection) Vibration Resistance: Up to 10 g, 10–2000 Hz Certifications / Standards Explosion Protection: Ex ia / Ex d / Ex nA options depending on code Compliance: ATEX, IECEx, PED, CE EMC & Surge Protection: Industrial-grade standards

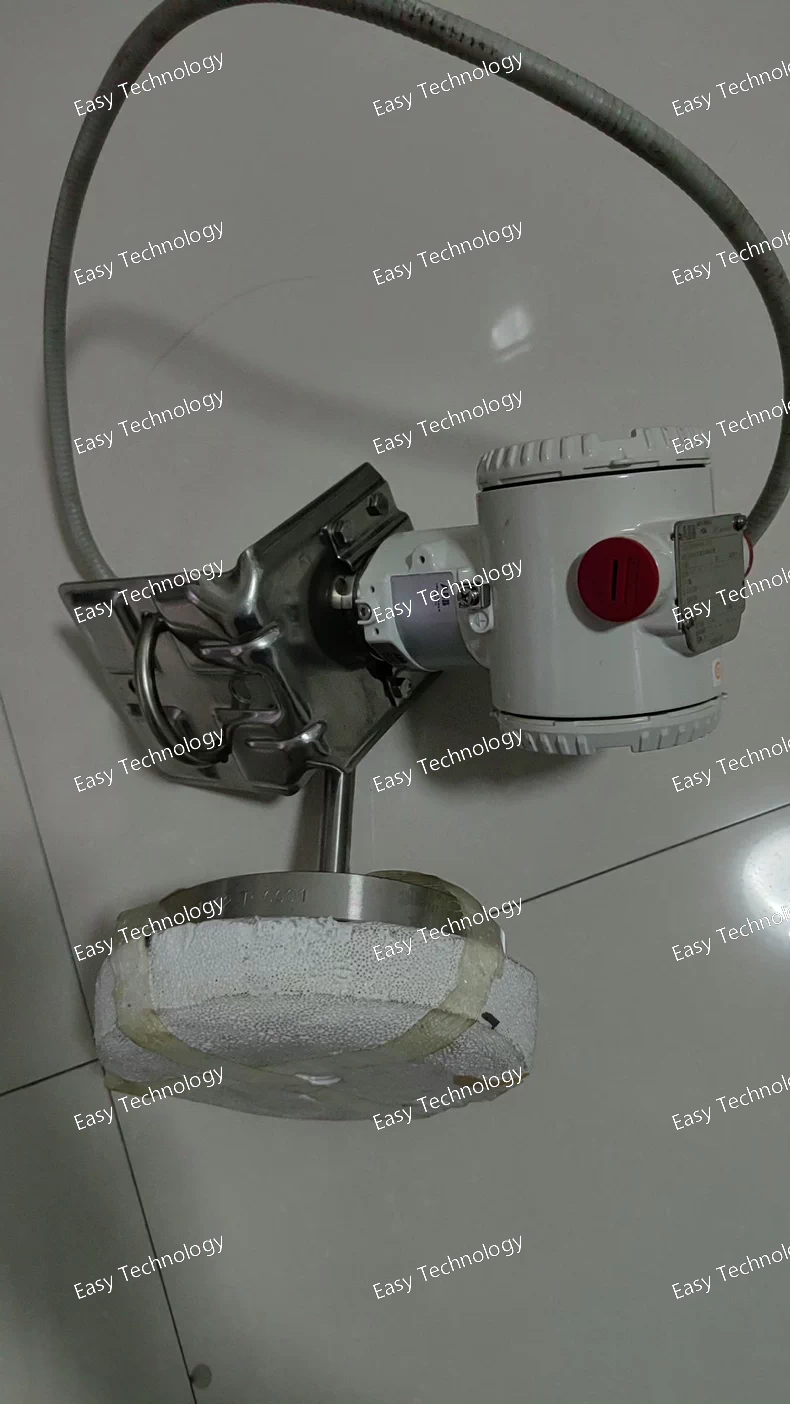

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 ASTC Output: 4–20 mA, two-wire with HART protocol Technology: Digital capacitive sensor with temperature compensation Measurement Performance Reference Accuracy: ±0.04% of span (depending on calibration) Repeatability: ±0.02% of span Turn-Down Ratio: Up to 100:1 Response Time: Typically <100 ms Long-Term Stability: ±0.1% of span over 10 years Pressure Ratings Differential Pressure Range: Configurable according to selected sensor range Static Pressure Limit: As defined by KBNB1 sensor module Overpressure Protection: Integrated mechanical system Mechanical / Materials Wetted Parts: Stainless steel (per KBNB1 selection) Fill Fluid: Silicone or inert oil (depending on configuration) Housing: Aluminum or stainless steel (per EYL1 selection) Process Connections: Standard 266 manifold or threaded connections Electrical Power Supply: 10.5–45 VDC Load Resistance: Up to 600 Ω (HART) Signal: 4–20 mA with HART digital output Local Configuration: Push-button interface if equipped Environmental Conditions Electronics Temperature Range: –40 to +85 °C Process Temperature: According to fill fluid and sensor selection Humidity: 0–100% RH (non-condensing) Ingress Protection: IP66 / IP67 depending on housing and entry options Vibration Resistance: Up to 10 g, 10–2000 Hz Certifications Explosion Protection: Ex ia / Ex d / Ex nA options depending on code Compliance: ATEX, IECEx, PED, CE Surge / EMC Protection: Per industrial standards

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 DSH (High Static Pressure Differential Model) Output: 4–20 mA with HART communication Sensor Type: Digital capacitive differential sensor Configuration Code: HSSA2B7LSTB Measurement Performance Reference Accuracy: Up to ±0.04% of span (depending on calibration) Long-Term Stability: ±0.1% of URL for up to 10 years Turn-Down Ratio: Up to 100:1 (application dependent) Response Time: Fast dynamic response suitable for flow monitoring Pressure Ratings Differential Pressure Range: As per DSH high-static sensor selection Static Pressure Limit: Up to 41 MPa / 6000 psi (DSH high-static variant) Overpressure Protection: Integrated mechanical overpressure system Materials Wetted Parts: Stainless steel (per “HSSA…” code) Fill Fluid: Silicone oil Sensor Body: High-strength stainless steel Housing: Aluminum housing with protective coating Process & Mechanical Process Connections: Standard 266 DP/DS manifold-style connections Mounting: Compatible with ABB 266 bracket and manifold systems Environmental Protection: IP66 / IP67 depending on electrical entry Electrical & Communication Communication Protocol: HART 7 Power Supply: 10.5–45 VDC depending on loop load Electrical Entry: As defined by “B7LSTB” configuration Zero/Span Adjustment: Via HART or local interface (if equipped) Environmental Conditions Ambient Temperature: –40 °C to +85 °C (electronics) Process Temperature: According to fill-fluid limitations EMI / RFI Immunity: Industrial-grade protection Certifications / Options Surge protection Harsh-environment enclosure options Industry-standard approvals depending on configuration

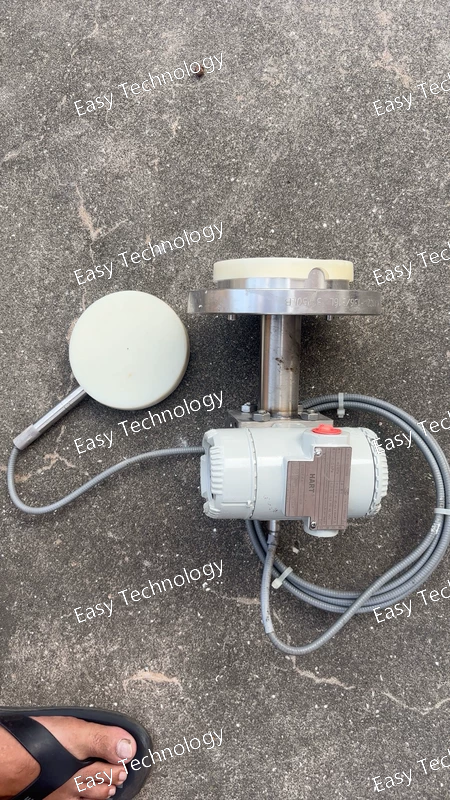

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 HSH (High Static Pressure Version) Output Signal: 4–20 mA with HART communication Technology: Digital capacitive sensor with advanced temperature compensation Measurement Performance Accuracy: Up to ±0.04% of calibrated span (depending on range) Long-Term Stability: Typically ±0.1% of URL for 10 years Response Time: Fast dynamic response suitable for flow applications Pressure Ratings Differential Pressure Range: According to HSH high static-pressure sensor limits Static Pressure Rating: Up to 41 MPa / 6000 psi (HSH high-static variant) Overpressure Protection: Integrated mechanical overpressure system Materials & Construction Wetted Materials: Stainless steel (per code “ESB…”) Fill Fluid: Silicone oil Housing: Aluminum housing with coating Process Connection: Standard 266 manifold-compatible connections Electrical & Communication Protocol: HART 7 Power Supply: 10.5–45 VDC (depending on load) Electrical Entry: As defined in “B6T…” portion of model code Certifications / Options Surge and transient protection Industrial environmental protection rating Mounting accessories per “L1B6TB” configuration Environmental Operating Temperature: –40 °C to +85 °C (electronics) Process Temperature: According to fill fluid limits Ingress Protection: IP66 / IP67 (depending on housing/entry selection)

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 Series Model: 266HSH – High Static Pressure DP Transmitter Output: 4–20 mA, two-wire with HART communication Measurement Performance Measured variable: Differential pressure (DP) Upper Range Limit (URL): Up to 10 MPa (depending on sensor range) Turn-down ratio: Up to 100:1 Reference accuracy: ±0.04% URL Repeatability: ±0.02% URL Long-term stability: ±0.1% URL over 10 years Response time: < 100 ms Adjustable damping: 0 to several seconds Pressure Ratings Static pressure rating: Up to 105 MPa (1050 bar) Proof pressure: 1.5 × static rating Overpressure protection: Integrated mechanical overload system Environmental Conditions Electronics operating temperature: –40 to +85 °C Process temperature: Depends on diaphragm and fill fluid selection Humidity: 0–100% RH (non-condensing) Vibration resistance: Up to 10 g, 10–2000 Hz Protection rating: IP67 / IP68 (depending on housing option) Electrical Characteristics Power supply: 10.5–45 VDC Signal: 4–20 mA + HART digital Load (HART): Up to 600 Ω Reverse polarity protection: Built-in EMC compliance: Meets IEC/EN industrial EMC standards Mechanical / Materials Wetted materials: Stainless steel, Hastelloy, or special alloys (per ESBA7 code) Process connections: High-pressure DP flanges or threaded adapters Fill fluid: Silicone oil or inert fluid (based on configuration) Housing: Aluminum or stainless steel (per LSTB selection) Mounting: Direct mount or mounting bracket options Display & Local Interface Local display: Optional LCD with bar-graph indication Local configuration: Two push-button setup Remote configuration: Via HART communicator, DTM, or EDD tools Certifications Explosion protection: Ex ia / Ex d / Ex nA (depending on selected code) Compliance: ATEX, IECEx, PED, CE Ingress protection: IP67 / IP68

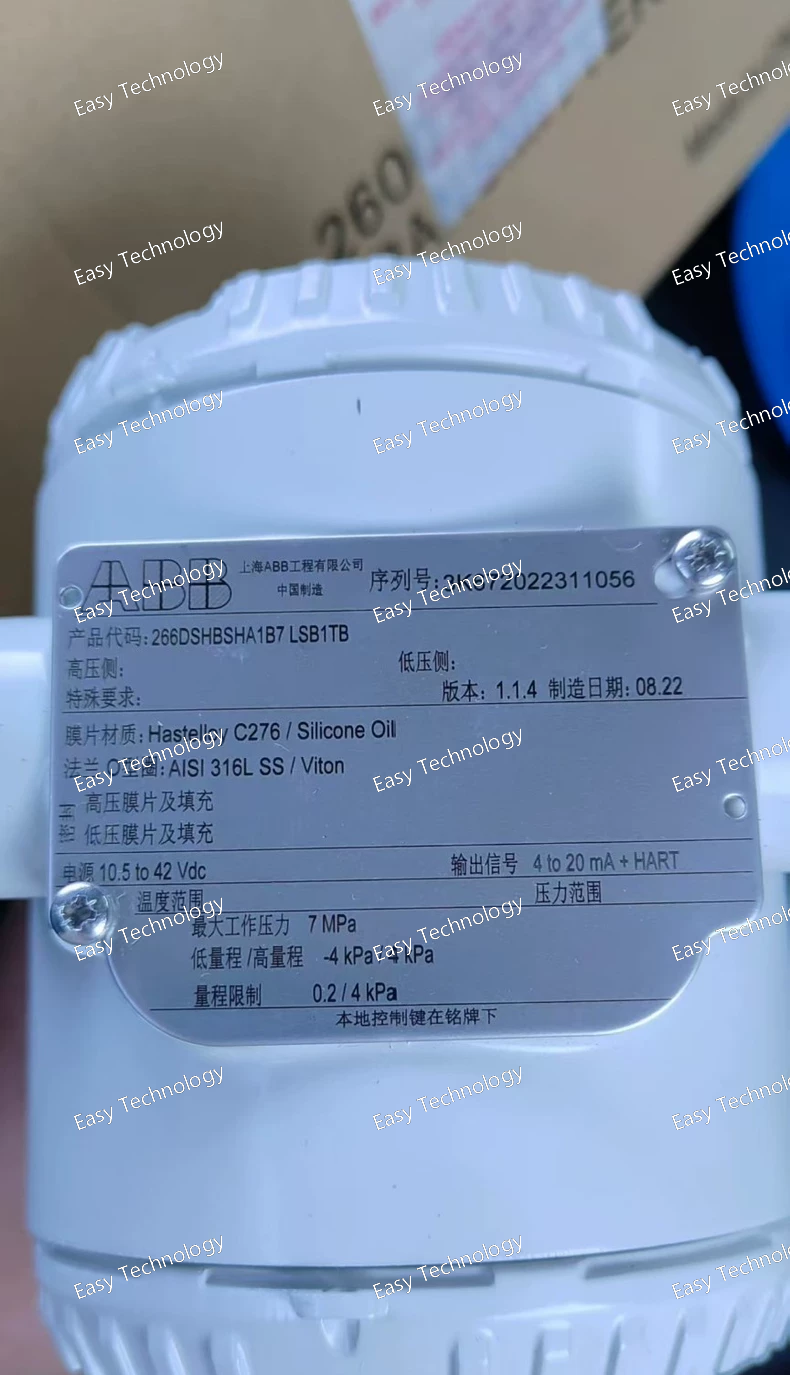

Specifications General Type: Differential Pressure Transmitter Series: ABB 266 Series Model: 266DSH – High Static Pressure DP Transmitter Output signal: 4–20 mA, two-wire with HART protocol Measurement Performance Measured variable: Differential pressure (DP) Upper Range Limit (URL): Up to 10 MPa (depending on selected sensor code) Turn-down capability: Up to 100:1 Reference accuracy: ±0.04% of URL Repeatability: ±0.02% of URL Long-term stability: ±0.1% URL over 10 years Damping: Adjustable (0 to several seconds) Response time: < 100 ms (depending on configuration) Pressure Limits Static pressure rating: Up to 41 MPa (410 bar) Proof pressure: 1.5 × static pressure rating Overpressure protection: Integrated mechanical overload system Environmental Conditions Electronics operating temperature: –40 to +85 °C Process temperature: Depends on diaphragm material and fill fluid Humidity: 0–100% RH, non-condensing Ingress protection: IP67 or IP68 (depending on housing option) Vibration resistance: Up to 10 g, 10–2000 Hz Electrical Characteristics Power supply: 10.5–45 VDC Load (HART): Max. 600 Ω Signal: 4–20 mA + HART digital Polarity protection: Built-in EMC compliance: Conforms to IEC/EN industrial EMC standards Mechanical / Materials Wetted materials: Stainless steel, Hastelloy, or optional alloys (based on BHA1B7 selection) Process connections: DP flanges or threaded high-pressure adapters Fill fluid: Silicone oil or inert fluid (per code BHA1B7) Housing: Aluminum or stainless steel (as specified in LSB1TB) Mounting: Direct mount or bracket installations Display & Local Interface Local display: Optional LCD with bar-graph and alphanumeric readout Local configuration: Two push-button interface Remote configuration: Via HART communicator or DTM/EDD tools Certifications Explosion protection: Options include Ex ia, Ex d, Ex nA (depending on device code) Compliance: ATEX, IECEx, PED, CE Ingress protection: IP67 / IP68 depending on terminal and housing type