PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

EPRO

Core Function: High-temperature eddy current sensor designed for extreme environment displacement monitoring in critical rotating equipment. Key Specifications: • Sensitivity: 8.0 mV/µm (±5%) • Measurement Range: 0-1.0mm (1000µm) • Frequency Response: DC to 10kHz • Temperature Range: -40°C to +200°C (peak 250°C) High-Temp Design Features: ✓ 8mm high-temperature probe ✓ M10×1 threaded mounting ✓ Mineral-insulated cable (5m standard) ✓ 20g vibration resistance ✓ 4MPa pressure rating Measurement Performance: Target material: AISI 4140 steel Linear range: 0.3-0.7mm (60% of full scale) Accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 systems • Special high-temp cable required • API 670 compliant Typical Applications: Gas turbine hot section monitoring Steam turbine high-temperature zones Petrochemical compressor trains

52

EPRO

Key Specifications: • Sensitivity: 8.0 mV/µm (±5%) • Measurement Range: 0-1.0mm (1000µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC linear signal Mechanical Design: ✓ 8mm diameter probe ✓ M10×1 threaded mounting ✓ Operating temperature: -30°C to +120°C ✓ Vibration resistance: 20g (50Hz) Measurement Performance: Target material: AISI 4140 steel Linear range: 0.3-0.7mm (60% of full scale) Accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 monitoring systems • Standard 5m/9m cable options • CON021 quick-disconnect available Typical Applications: Turbine shaft vibration monitoring Compressor thrust position measurement Industrial pump/fan protection Compliance: Meets API 670 machinery protection standards Special Features: Optimized for standard-range displacement measurements Rugged industrial construction Reliable performance in harsh environments

960

EPRO

Core Function: Industrial eddy current sensor for wide-range displacement monitoring in heavy rotating equipment. Key Specifications: • Sensitivity: 1.4 mV/µm (±5%) • Extended Range: 0-14mm (14,000µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC linear signal Mechanical Configuration: ✓ 8mm diameter probe ✓ M10×1 threaded mounting ✓ -30°C to +120°C operation ✓ 20g vibration resistance Measurement Performance: Target material: AISI 4140 steel Linear range: 4.2-9.8mm (60% of full scale) Typical accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 systems • Standard 5m/9m cable options • CON021 quick-disconnect available Special Features: Optimized for large clearance applications Maintains stability in high-vibration environments Wide linear measurement range Typical Applications: Large turbine shaft monitoring Heavy compressor axial displacement Industrial machinery with wide gaps Compliance: Meets API 670 machinery protection standards

64

EPRO

Key Specifications: • Sensitivity: 8.0 mV/µm (±5%) • Measurement Range: 0-1.0mm (1000µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC linear signal Robust Design Features: ✓ 8mm industrial-grade probe ✓ M10×1 threaded mounting ✓ -30°C to +120°C operation ✓ 20g vibration resistance ✓ 4MPa pressure rating Measurement Performance: Target material: AISI 4140 steel Linear range: 60% of full scale Accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 systems • 5m high-flexibility shielded cable (standard) • CON021 quick-disconnect option Special Features: /10R designation indicates ruggedized construction Enhanced cable durability for harsh environments Reliable performance in high-vibration applications Typical Applications: Turbine shaft vibration monitoring Compressor thrust position measurement Heavy industrial machinery protection Compliance: Meets API 670 machinery protection standards

777

EPRO

Key Features: • Modular Design: Scalable from 4 to 12 channels • Multi-Parameter Monitoring: ✓ Vibration (velocity/displacement) ✓ Shaft position ✓ Speed/RPM ✓ Temperature (RTD/TC) Technical Specifications: Input Compatibility: • Eddy current probes (PR642x/PR9268) • Velocity sensors (4-20mA/0-10V) • Tachometers (5-15V pulse) • RTDs/thermocouples Accuracy: ±1% FS Sampling Rate: 1kHz/channel Communication & Outputs: ✓ 4-20mA analog outputs (per channel) ✓ Programmable alarm relays ✓ RS-485 Modbus + Ethernet ✓ Optional Profibus-DP System Integration: CMS 2000 configuration software Rack-mounted IP20 enclosure -20°C to +70°C operation Typical Applications: Power plant turbine supervision Large compressor train monitoring Critical generator protection Compliance: API 670, ISO 10816, CE, UL certified Advantage: Flexible expansion capability for growing monitoring needs (Ideal for centralized plant-wide machinery protection systems)

734

EPRO

Key Specifications: • Channels: 2 fully independent DSP-processed inputs • Measurement Ranges: Vibration: 0-500 µm pk-pk Displacement: 0-2.0 mm Speed: 0-20,000 RPM • Accuracy: ±0.5% FS • Sampling Rate: 2kHz/channel Advanced Features: ✓ Digital signal processing (DSP) technology ✓ Real-time waveform capture ✓ Predictive maintenance diagnostics ✓ Ethernet/IP & Modbus RTU communication I/O Configuration: 2x isolated 4-20mA outputs 4x alarm relays (SPDT) RS-485 + Ethernet standard Environmental Ratings: Power: 24V DC or 100-240V AC Operating Temp: -20°C to +70°C Enclosure: IP40 panel-mount Typical Applications: Steam/gas turbine supervisory systems Critical compressor protection Power generation equipment Compliance: API 670, ISO 10816, CE, UL Special Notes: "D" model features enhanced digital processing Supports CMS 2000 configuration software Optional ATEX versions available

330

EPRO

Key Features: ✔ ±50g measurement range (100mV/g sensitivity) ✔ Wide frequency response (0.5Hz–5kHz) ✔ IP68-rated for dust/water resistance ✔ M12 connector for secure connectivity ✔ ATEX/IECEx options available Technical Specifications: Output: IEPE (±5V) Power: 18-30VDC (2-10mA constant current) Operating Temp: -40°C to +120°C Mounting: M6 threaded stud Shock Resistance: 500g Typical Applications: Pump and motor condition monitoring Compressor vibration analysis Fan and blower diagnostics Structural health assessment Certifications: CE, SIL 2 compliant ATEX/IECEx versions available ISO 10816/20816 compliant Why Choose A6220? Military-grade durability with stainless steel housing Plug-and-play integration with EPRO systems 5-year warranty for assured performance

709

EPRO

Key Features: 8mm stainless steel probe with M10×1 threading 0.5-2.5mm measuring range (8mV/µm sensitivity) Wide frequency response (0-10kHz) IP67 environmental protection MIL-spec threaded connector Technical Specifications: Power supply: -18 to -24VDC (±10%) Output signal: -2 to -18VDC Operating temperature: -40°C to +100°C ±1% linearity across full range 5m standard cable (extendable to 300m) Performance Highlights: ±0.5µm repeatability 100 bar pressure rating 500N axial load capacity NIST-traceable calibration available Typical Applications: Industrial pump monitoring Steam turbine shaft vibration Compressor rotor position Paper manufacturing equipment General rotating machinery Certifications: CE and RoHS compliant Meets API 670 (4th Ed.) and ISO 7919 ATEX option available Installation Notes: Requires carbon steel targets (AISI 4140 recommended) 20-30N·m mounting torque Proper grounding required for optimal performance

494

EPRO

Key Features: 8mm stainless steel probe with M10×1 threading 0.5-2.5mm measuring range (8mV/µm sensitivity) Wide frequency response (0-10kHz) IP67 environmental protection 150 bar pressure rating Technical Specifications: Power supply: -18 to -24VDC (±10%) Output signal: -2 to -18VDC Operating temperature: -40°C to +125°C ±1% linearity across full range 5m standard cable (extendable to 500m) Performance Highlights: ±0.5µm repeatability 50g vibration resistance MIL-spec connector for secure connections NIST-traceable calibration available Typical Applications: Steam turbine shaft monitoring Compressor rotor position measurement Hydroelectric generator bearings Critical pump train protection General industrial rotating equipment Certifications: Complies with API 670 (4th Ed.) Meets ISO 7919 standards CE marked (ATEX optional) SIL 2 capable Installation Notes: Requires carbon steel targets (AISI 4140 recommended) 25N·m mounting torque Proper grounding required for optimal performance

807

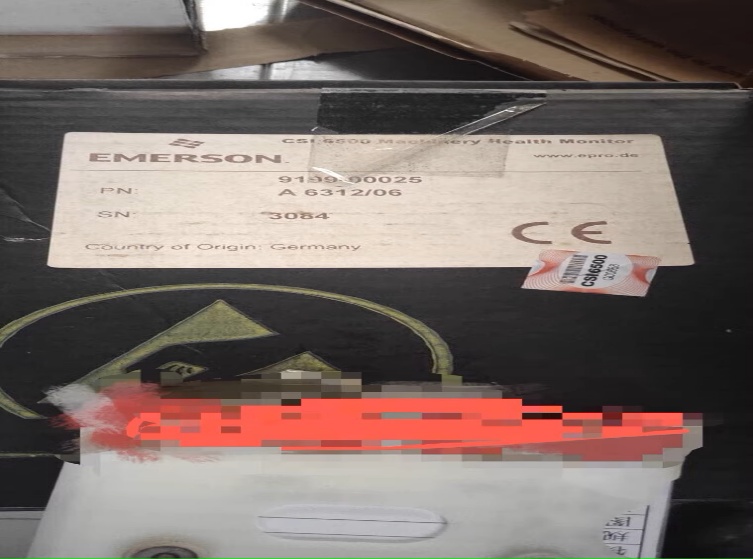

EPRO

Key Features ✔ Triaxial MEMS sensor (±50g per axis) ✔ Dual output options: 4-20mA or IEPE ✔ Wide frequency range (0.5Hz–5kHz) ✔ IP68 stainless steel housing ✔ M12 connector for secure connectivity Technical Highlights Sensitivity: 100mV/g ±3% Operating Temp.: -40°C to +85°C Shock Resistance: 1000g Cross-Talk: <2% between axes Mounting: M6 threaded stud Typical Applications Gearbox vibration analysis Pump/motor condition monitoring Structural health assessment Wind turbine nacelles Heavy rotating equipment Certifications & Options CE, SIL 2 compliant ATEX/IECEx versions available NIST-traceable calibration Why Choose A6312? Simultaneous 3-axis measurement saves installation space Military-grade durability (IP68/1000g shock) Plug-and-play with EPRO monitoring systems TÜV-certified for safety applications

679

EPRO

Key Features ✔ Wide measuring range: 1–50,000 RPM (±0.01% accuracy) ✔ Triple protection setpoints: Warning/Danger/ESD ✔ <10ms response time – industry-leading for overspeed events ✔ Dual sensor inputs (MPU/proximity) for redundancy ✔ SIL 2 certified (SIL 3 option available) Technical Specifications Inputs: Magnetic pickup (MPU) or proximity probe (1–60 pulses/rev) Outputs: 4× SPDT relays (250VAC/5A) 4–20mA analog output RS-485 Modbus RTU Display: 5-digit LED with 0.1 RPM resolution Power: 24VDC or 85–264VAC Safety & Protection Programmable trip delays (0.1–60 seconds) Self-diagnostics for sensor health monitoring Event logging (last 10 trips) TÜV-certified protection logic Typical Applications Steam/gas turbine overspeed protection Critical compressor trains Power generation equipment High-speed pump monitoring Certifications & Options ATEX/IECEx Zone 1 (optional) SIL 2/3 compliant versions CE, UL, API 670 (5th Ed.) Why Choose TES835S? Military-grade reliability for mission-critical systems Flexible integration with PLC/DCS via Modbus Rugged IP65 aluminum housing 5-year warranty on electronics

670

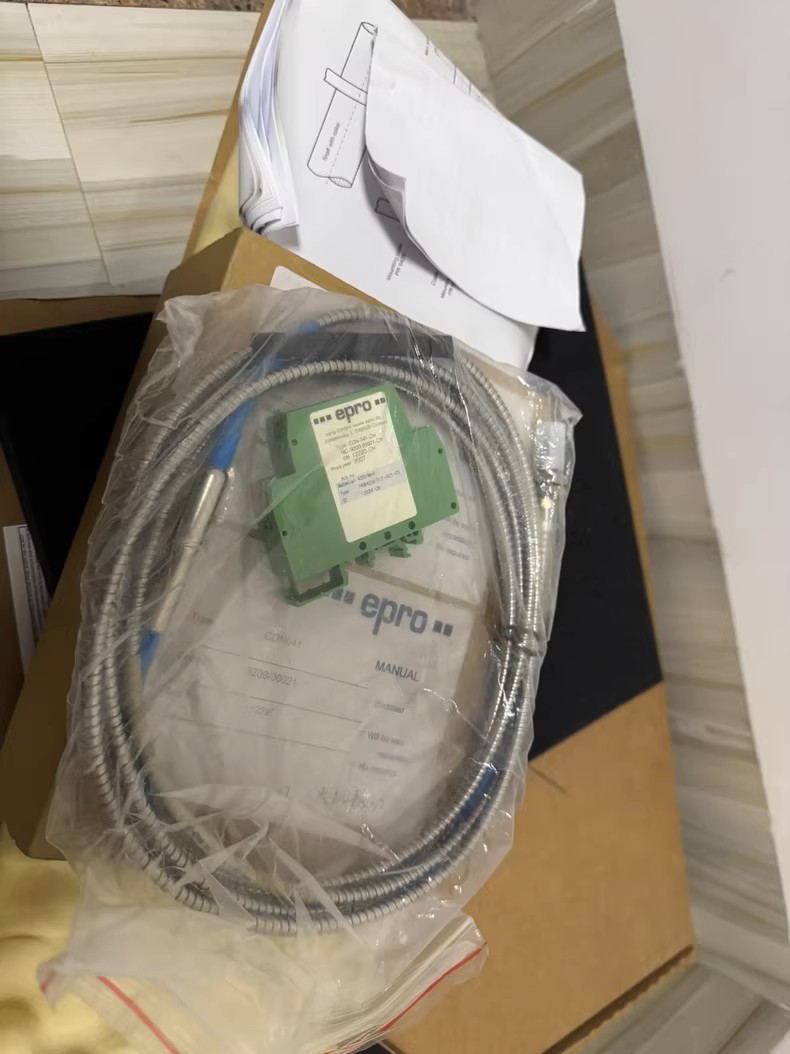

EPRO

Core Functionality: The EPRO CON041 is a multi-channel signal conditioner designed to process vibration and position signals from industrial sensors (eddy current probes, accelerometers, 4-20mA). It ensures noise-free, isolated signals for PLC/DCS integration. Key Features ✔ 4 isolated channels (eddy current, IEPE, 4-20mA, RTD) ✔ Dual outputs: 4-20mA and ±10V (per channel) ✔ High accuracy: ±0.1% FS with 10kHz sampling ✔ Modbus RTU & PROFIBUS-DP communication ✔ IP66 front panel (DIN rail or panel mount) Technical Highlights Inputs: DC-15kHz (±3dB), ±10V / 4-20mA Outputs: 4-20mA (loop-powered) or ±10V analog Power: 24VDC or 100-240VAC Isolation: 1500VDC (channel-to-channel) Operating Temp.: -20°C to +70°C Applications Turbine/compressor monitoring Retrofitting legacy systems PLC/DCS signal conditioning Predictive maintenance setups Certifications & Options CE, RoHS compliant ATEX/IECEx version available (CON041-EX) SIL 2 capable (with TÜV certification) Why Choose CON041? Flexible input/output configurations Industrial-grade noise immunity Seamless EPRO ecosystem integration Compact DIN rail design

553