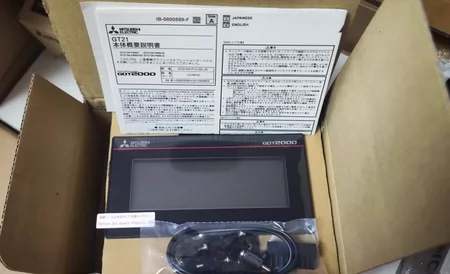

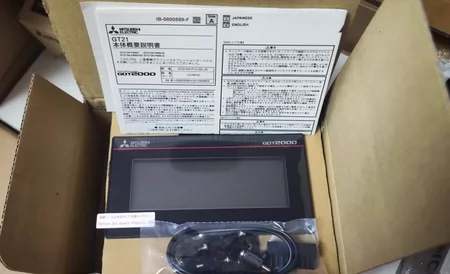

GT2104PMBDS

The Mitsubishi GT2104PMBDS is a high-performance Human-Machine Interface (HMI) from the GT21 series. It features a 10.4-inch TFT display with an intuitive interface, designed to enable seamless interaction between operators and machinery or automation systems. This HMI is widely used in industrial applications to provide clear visual feedback and enable efficient control of various systems such as PLC-based automation, machine tools, production lines, and HVAC systems.

DESCRIBE

Key Features:

Type: HMI (Human-Machine Interface)

Model: GT2104PMBDS

Series: GT21 Series

Display Type:

10.4-inch TFT color display

Resolution: 800 × 600 pixels (SVGA)

Display Colors: 65536 colors (high-quality visual feedback)

Backlight: LED backlight for long lifespan and energy efficiency

Touch Panel:

Resistive touchscreen for easy and precise user interaction

Multi-touch support for modern interaction methods

Touchscreen durability with long-lasting resistance to wear and tear

Communication Interfaces:

Supports a wide range of communication protocols including Ethernet, RS-232, RS-485, and USB

Integrated with MELSEC PLCs and other industrial controllers through Ethernet/IP, Modbus, and other communication options

USB Host and USB Client interfaces for easy data exchange and peripheral connectivity

I/O Expansion:

Supports I/O expansion to connect additional devices, sensors, and controllers

Facilitates real-time monitoring and feedback for connected systems

Programmable Logic Controller (PLC) Integration:

Compatible with Mitsubishi MELSEC PLCs and other leading PLC brands

Provides easy programming via GX Works2/3 or GT Designer3

Ability to visualize, monitor, and control automation processes with real-time data

Display Features:

High-contrast display for clear visibility even in challenging lighting conditions

Customizable screen layouts to match specific application needs

Multilingual support to cater to global industrial environments

Software Support:

Supports Mitsubishi's GT Designer 3 for programming, graphical creation, and easy configuration

Pre-installed with a wide range of libraries for quick and simple application development

Alarms, data logging, and real-time graphs for enhanced system diagnostics

Operating System:

Embedded operating system optimized for industrial use

Fanless design for quieter operation and higher reliability

Protection:

IP65 rating (front) for protection against dust and water splashes

Vibration resistance for operation in industrial environments

Wide operating temperature range suitable for demanding applications

Specifications / Parameters:

Display:

Size: 10.4 inches (TFT)

Resolution: 800 × 600 (SVGA)

Display Colors: 65536 colors (16-bit)

Backlight: LED

Touch Panel:

Type: Resistive touchscreen

Touch Durability: Designed for long-lasting use in industrial settings

Communication Ports:

Ethernet: 1 x 100BASE-TX

RS-232: 1 x (for communication with PLCs or other devices)

RS-485: 1 x (for additional industrial communication)

USB: 1 x Host USB port, 1 x Client USB port

SD Card Slot: For data storage and backup

Power Supply:

Voltage: 24 V DC (allowing for wide voltage variations in industrial settings)

Power Consumption: Approx. 20 W

Processor and Memory:

Processor: High-performance CPU designed for rapid response and real-time processing

Memory: Sufficient RAM and flash memory for storing configurations, application data, and user settings

Environmental Durability:

Operating Temperature: 0°C to +50°C

Storage Temperature: -20°C to +60°C

Humidity: 10% to 90% RH (non-condensing)

Protection Class: IP65 (front), suitable for industrial environments with dust and water exposure

Dimensions:

Width: 252 mm

Height: 199 mm

Depth: 48 mm

Weight: Approx. 1.7 kg

Applications:

Industrial Automation: Perfect for monitoring and controlling automated processes in manufacturing, assembly lines, and robotic systems

Machine Tools: Used in CNC machines, milling machines, and lathes for controlling and monitoring operations

Material Handling: For real-time visualization and control of conveyor belts, sorting systems, and automated material handling equipment

HVAC Systems: Ideal for controlling HVAC equipment such as pumps, fans, air conditioners, and heating units

Building Automation: Suitable for managing building systems, including lighting, security, and energy management

Water Treatment: Controls pumps, filtration systems, and other equipment in water and wastewater treatment plants

Packaging Systems: Used in packaging lines, labeling systems, and automated packaging equipment to control operations and visualize real-time data