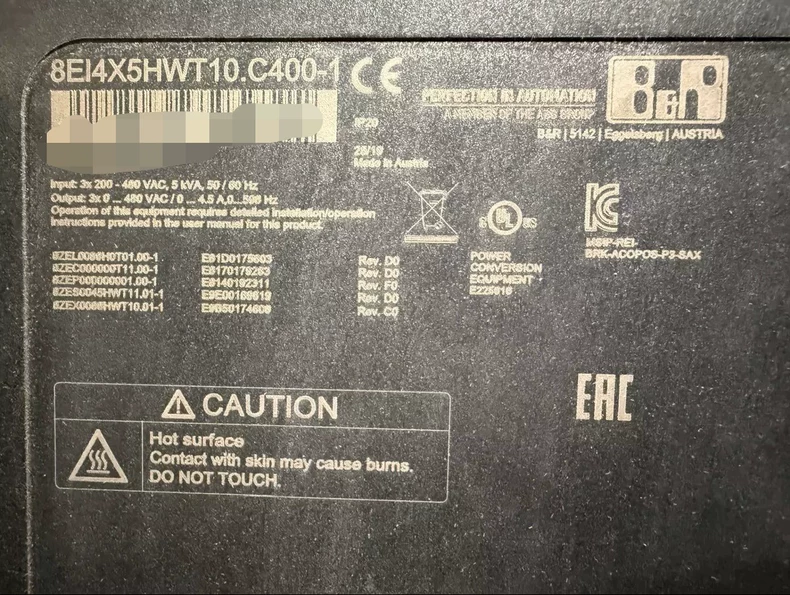

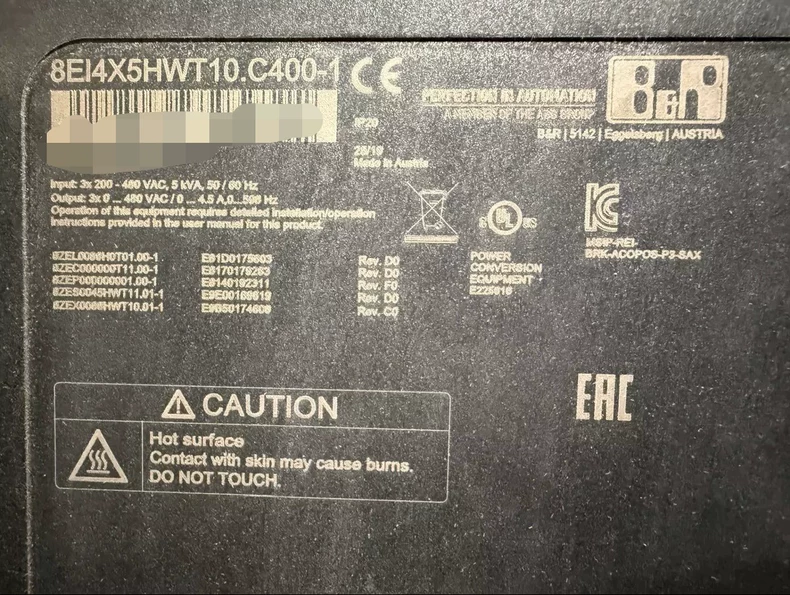

8EI4X5HWT10.C400-1

The B&R 8EI4X5HWT10.C400-1 is a specialized industrial input/output (I/O) module designed for use in demanding automation systems. It provides seamless integration of digital inputs and outputs, enabling efficient control and monitoring in factory automation, machine control, and process monitoring systems. The module is engineered for reliability, robustness, and ease of integration into existing industrial control networks.

DESCRIBE

Detailed Description:

Type: Industrial I/O Module

The 8EI4X5HWT10.C400-1 is a high-performance I/O module that facilitates the integration of sensors, actuators, switches, and other field devices with industrial control systems. It supports a combination of digital inputs and outputs, making it ideal for use in a variety of industrial applications that require accurate data acquisition and control.

Application:

This module is designed for factory automation, machine control, data acquisition, and process monitoring systems. It ensures efficient data exchange between field devices and central control systems, allowing for real-time monitoring and control of industrial processes.

Power Supply:

The 8EI4X5HWT10.C400-1 operates on a 24V DC power supply, providing stable and reliable performance suitable for most industrial applications. The 24V DC standard ensures compatibility with a wide range of devices and systems in automation networks.

Mounting: DIN Rail Mountable

The 8EI4X5HWT10.C400-1 is designed for DIN rail mounting, which is the most common method of installation in industrial environments. This feature ensures easy integration into existing control cabinets, optimizing space usage and providing secure mounting for the module.

Inputs/Outputs:

Inputs: 4 digital inputs (24V DC)

Outputs: 5 digital outputs (24V DC, relay-controlled)

The module provides a combination of digital inputs and digital outputs, allowing it to interface with a wide range of field devices. These include sensors, switches, actuators, and other components, enabling precise control and monitoring.

Communication Protocols:

The 8EI4X5HWT10.C400-1 supports industrial communication protocols, which allows seamless integration with controllers, sensors, actuators, and other components within an industrial network. This ensures real-time data exchange, enabling efficient control of industrial processes.

Temperature Range:

The 8EI4X5HWT10.C400-1 operates in a wide temperature range from -20°C to +60°C, making it suitable for deployment in industrial environments subject to varying temperature conditions. This temperature range ensures reliable performance in both low and high-temperature environments.

Protection:

The module is designed to be dust and moisture resistant, ensuring long-lasting and reliable performance in industrial environments where exposure to contaminants and moisture is common.

Size & Form Factor:

The 8EI4X5HWT10.C400-1 is compact and optimized for DIN rail installation, offering space-saving installation while maintaining high functionality. Its compact design ensures that it can be easily integrated into control panels without compromising system performance.

Key Parameters:

Type: Industrial I/O Module

Power Supply: 24V DC

Mounting: DIN Rail Mountable

Inputs: 4 digital inputs (24V DC)

Outputs: 5 digital outputs (24V DC, relay-controlled)

Temperature Range: -20°C to +60°C

Protection Rating: Dust and moisture resistant

Communication: Supports multiple industrial communication protocols

Size: Compact, optimized for DIN rail installation

Applications:

Factory Automation: The 8EI4X5HWT10.C400-1 enables control and monitoring of industrial devices like sensors, actuators, and switches, contributing to the automation of manufacturing processes and improving overall system efficiency.

Machine Control: This module is used for managing the inputs and outputs of machinery, ensuring real-time control and smooth operation in industrial settings.

Process Monitoring: Ideal for monitoring processes in various industries, such as chemical, food production, or energy, by providing real-time data and feedback for system optimization.

Data Acquisition & Monitoring: Collects data from field devices and sensors, helping to monitor system performance and enabling informed decision-making for process optimization.