PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

Key Features Circuit Breaker Type: Molded Case Circuit Breaker (MCCB) with fixed thermal‑magnetic trip unit — protects against overloads and short‑circuits. Frame Size: A2 — accommodates ratings from roughly 125 A up to 250 A. Poles: 1‑, 2‑, 3‑, or 4‑pole configurations for single‑phase and three‑phase systems. Mounting: Fixed, front terminal type — installs directly on panel back plates or distribution board backplanes. Trip Unit: Thermomagnetic with fixed thresholds, providing simple, ready‑to‑use protection. Compact Size: Smaller footprint compared to larger breaker families, helping save panel space. Electrical Ratings Rated Operational Current (In): Up to ~250 A continuous current capacity. Rated Insulation Voltage (Ui): Up to ~690 V AC. Rated Operational Voltage: Suitable for AC systems up to standard low‑voltage distribution levels (~550–690 V depending on the variant). Rated Impulse Withstand Voltage (Uimp): Approximately 6 kV transient withstand capability. Trip Characteristic: Thermomagnetic with fixed overload and instantaneous short‑circuit protection. Short‑Circuit Breaking Capacity: Robust interrupt rating suitable for general distribution panel duties. Mechanical & Environmental Durability: Engineered for a high number of mechanical and electrical operations over its service life. Operating Conditions: Suitable for typical electrical enclosure environments in industrial and commercial installations. Installation: Front‑accessible screw/clamp terminals for secure cable connections. Typical Applications Branch‑circuit protection in industrial and commercial distribution boards. Motor feeder and load protection in machinery panels. Control panel protective element for power circuits requiring reliable overload and short‑circuit interruption. General electrical safety protection in low‑voltage systems where basic fixed protection is required.

Key Features Circuit Breaker Type: Fixed molded case circuit breaker with thermomagnetic protection. Poles: 3 poles for three‑phase system protection. Trip Mechanism: Thermo‑magnetic (TMF) — combines thermal overload and instantaneous magnetic short‑circuit protection. Front Terminals: Easy front access for incoming and outgoing conductors. Compact Design: Space‑saving profile for panel and switchboard integration. Electrical Specifications Rated Current (Main Circuit): 200 A — continuous operating current capacity. Rated Operational Voltage: Up to 550 V AC and 250 V DC in low‑voltage systems. Rated Insulation Voltage: 690 V — withstands standard electrical insulation requirements. Rated Impulse Withstand Voltage (Uimp): 6 kV — robust against transient overvoltages. Rated Service Short‑Circuit Breaking Capacity (Ics): Example values: ~42.5 kA at 240 V AC; ~18 kA at 380–415 V AC; ~12.5 kA at 440–480 V AC; lower DC. Rated Ultimate Short‑Circuit Breaking Capacity (Icu): Example values: ~85 kA at 240 V AC; ~36 kA at 380–415 V AC; ~25 kA at 440–480 V AC; lower DC. Rated Uninterrupted Current (Iu): 250 A — maximum conductor thermal rating. Mechanical & Endurance Electrical Durability: Designed for ~4,000 switching cycles under load. Mechanical Durability: Designed for ~10,000 mechanical operations. Opening Time: Fast internal response (~15 ms) under specified conditions. Environmental & Standards Standards Compliance: Built to international low‑voltage protection standards. Operating Conditions: Suitable for typical control panel and distribution board environments. Physical & Installation Mounting: Panel or enclosure installation with front‑accessible terminations. Compact Dimensions: Efficient size for space‑constrained installations. Terminal Type: Screw/clamp‑style front connections. Typical Applications Low‑voltage power distribution in industrial and commercial panels. Branch and feeder protection for motors, transformers, and loads. Control and automation panels where robust protection and compact size are key. General safety overcurrent protection in three‑phase systems.

Key Features Circuit Breaker Type: Fixed molded case circuit breaker with thermomagnetic protection. Poles: 3 poles for three‑phase circuit protection. Trip Mechanism: Thermal‑magnetic (TMF) — provides overload and short‑circuit protection. Front Terminals: Designed for easy front access connections for incoming and outgoing conductors. Compact Design: Slim profile suited for modular panel installations. Electrical Ratings Rated Current (In): 63 A — continuous current capacity of the main circuit. Rated Uninterrupted Current (Iu): 125 A — maximum continuous conductor rating of the breaker frame size. Rated Operational Voltage: 550 V AC for AC power distribution. 250 V DC for DC systems. Insulation Voltage (Ui): 690 V — withstands common low‑voltage system insulation requirements. Impulse Withstand Voltage (Uimp): 6 kV — resistance to high voltage transients. Service Short‑Circuit Breaking Capacity (Ics): Varies by voltage, typically several kiloamperes in AC systems. Ultimate Short‑Circuit Breaking Capacity (Icu): Higher fault‑current interruption capability rated by voltage system. Rated Frequency: Suitable for 50 Hz / 60 Hz systems. Mechanical & Performance Durability: Electrical Life: Rated for thousands of operations under load. Mechanical Life: Designed for repeated operation cycles. Performance Level: Suitable for general power distribution and protection. Operating Environment: Typical industrial ambient conditions inside enclosed panels. Physical & Installation Mounting: Panel or enclosure mounted. Terminals: Screw/clamp front terminals for secure conductor connections. Frame Size: Compact MCCB frame for space‑efficient distribution boards. Weight & Footprint: Moderate weight and size suitable for standard low‑voltage switchgear. Typical Applications Low‑voltage distribution boards in industrial and commercial buildings. Branch circuit protection for feeder circuits and motor loads. Control panels and machinery power isolation where reliable overcurrent protection is needed. General electrical safety against overloads and short circuits.

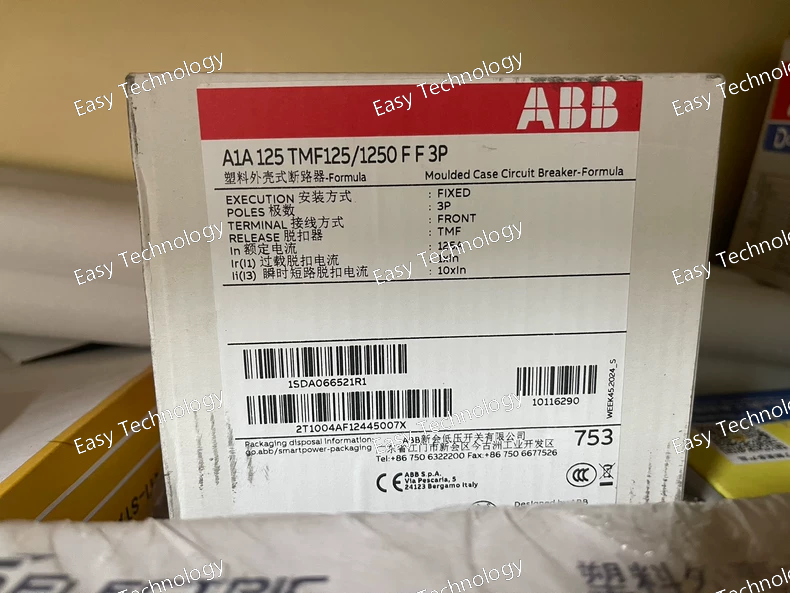

Key Features Circuit Breaker Type: 3‑pole fixed molded case circuit breaker (MCCB). Trip Unit: Thermomagnetic (TMF) release — offers overload and short‑circuit protection in one unit. Terminal Type: Front terminals for easy connection in panel or distribution board installations. Compact Design: Space‑efficient profile suitable for modular panel layouts. Durability: Engineered for frequent switching and fault interruption cycles. Electrical Ratings Rated Current (In): 125 A — continuous load capacity. Rated Operational Voltage: Suitable for AC systems up to ~550 V AC and DC up to ~250 V DC. Rated Insulation Voltage (Ui): ~690 V. Impulse Withstand Voltage (Uimp): ~6 kV. Rated Ultimate Short‑Circuit Breaking Capacity (Icu): High breaking capacity appropriate for industrial power distribution levels. Service Short‑Circuit Breaking Capacity (Ics): Substantial portion of Icu to provide dependable service interruption performance. Operating Frequency: Designed for standard industrial power frequencies (50/60 Hz). Tripping Mechanism: Thermal element: Protects against sustained overloads. Magnetic element: Instantaneous protection against high short‑circuit currents. Mechanical & Environmental Number of Poles: 3 poles — simultaneous protection of all three phases in three‑phase systems. Electrical Durability: Rated for multiple make/break cycles throughout service life. Mechanical Durability: Built for a high number of mechanical operations. Operating Temperature Range: Suitable for typical industrial ambient conditions. Enclosure Protection: Intended for installation inside electrical panels or enclosed distribution boards with appropriate protection ratings. Physical & Installation Mounting: Panel or enclosure installation, front‑accessible connections. Terminals: Front‑tie connections for convenient wiring. Dimensions: Compact footprint that fits standard industrial panel layouts. Weight: Designed to balance robustness with manageable physical size. Typical Applications Branch‑circuit protection in industrial and commercial power distribution. Protection of motor feeders, transformers, and distribution circuits in machinery and plant installations. Main or sub‑panel protection where a reliable breaker with thermomagnetic trip characteristics is required. Load isolation and system safety in electrical switchboards and control cabinets.

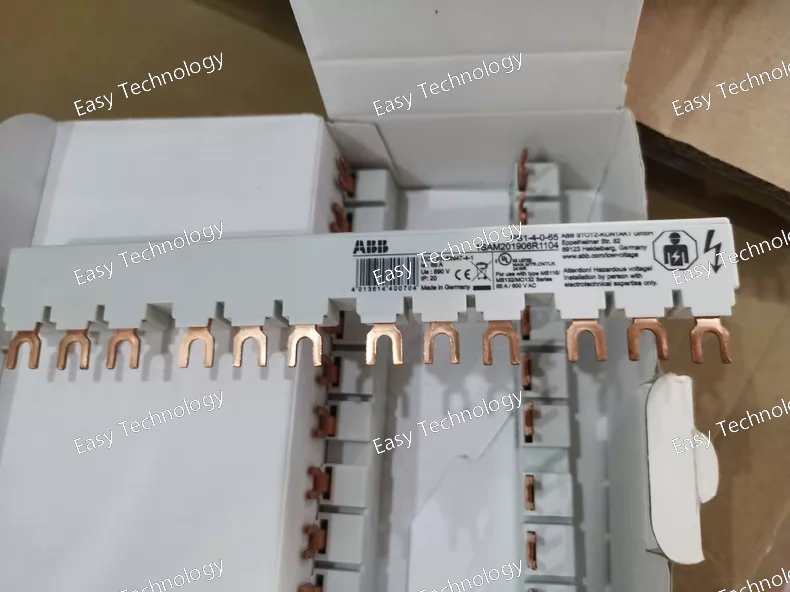

Key Features 3‑phase busbar for four positions, enabling parallel connection of up to four manual motor protectors. Designed for compact motor protection installations and modular panels. Space‑efficient, straight‑bar design for clean connections. Common feed distribution for L1, L2, and L3 phases. Electrical Ratings Rated Operational Current: 65 A — supports a continuous current up to this value for each phase. Rated Operational Voltage: Suitable for low‑voltage AC applications up to 690 V and also compatible with lower DC voltages (e.g., 250 V). Short‑Circuit Capability: High short‑circuit withstand capability for robust performance in industrial systems. Rated Impulse Withstand Voltage: Designed to tolerate voltage transients up to several kilovolts in control and distribution circuits. Mechanical & Environmental Number of Poles / Phases: 3 poles (L1, L2, L3) for three‑phase systems. Number of Mountable Devices: 4 positions for up to four manual motor protectors. Connection Style: Fork‑type busbar connection for secure mechanical and electrical engagement. Protection Rating: IP20 when installed inside an electrical enclosure — touch protection for terminals. Pollution Degree: Suited for typical industrial environments. Physical & Installation Length: ~176.5 mm — compact footprint for modular wiring lanes. Height: ~32.3 mm Depth: ~13 mm Weight: Lightweight bar section for easy handling and installation. Mounting: Designed to be placed between manual motor protectors and to align with their terminals without additional hardware. Typical Applications Parallel feed distribution for MS116 / MS132 manual motor protectors in motor control centers and equipment panels. Wiring simplification in low‑voltage power distribution cabinets. Industrial control panels where multiple protective devices share a common supply. OEM and retrofit applications aiming to reduce wiring time and errors.

Key Features Selector Type: 3‑position maintained rotary selector switch. Actuator: Short red handle for intuitive manual operation. Design: Non‑illuminated selector with a chrome metal bezel and robust construction. Function: Maintained — the switch stays in the selected position until changed by the operator. Compact Range: Space‑efficient design for standard control panels. Electrical Ratings Contact Configuration: 2 Normally Open (2 NO) auxiliary contacts for control circuit switching. Rated Operational Voltage: Up to 300 V AC/DC in typical control system environments. Rated Operational Current: Suitable for AC‑15 control duties (e.g., around 1 A at 220–240 V AC). Suitable for DC‑13 control duties at lower DC voltages. Rated Insulation Voltage: Designed for standard low‑voltage control circuits. Rated Impulse Withstand Voltage: Suitable withstand for transient events in normal use. Mechanical & Environmental Positions: Three fixed maintained positions (A, B, C). Mechanical Durability: Designed for a high number of operations in industrial settings. Operating Temperature Range: Suitable for typical industrial ambient conditions. Storage Temperature Range: Broader range for shipping and storage conditions. Protection: Good ingress protection at the front when correctly mounted; terminals protected when installed inside an enclosure. Physical & Installation Panel Cut‑out: Fits a standard 22 mm pilot device cut‑out. Bezel Material: Chrome metal for durability and panel aesthetics. Housing: Plastic body suitable for industrial environments. Terminals: Screw‑type terminals for secure wiring. Typical Applications Mode selection (e.g., Off/Auto/Manual) in industrial control panels. Operator interfaces for machinery and process control equipment. Control logic inputs for PLCs, relays, and contactor systems. Multi‑position manual selection for automation systems.

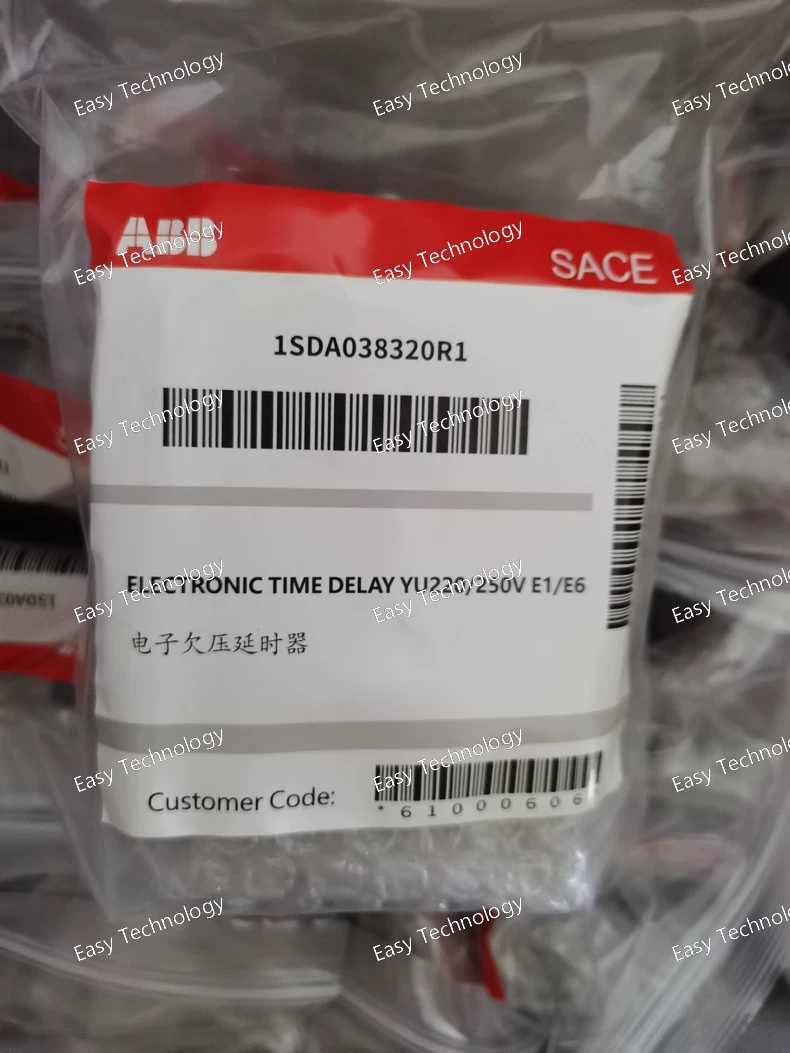

Key Features Time Delay Function: Adds an adjustable electronic delay before breaker opening on undervoltage or specified trigger. Compatible with Multiple Breaker Series: Fits a range of ABB breakers including the Tmax XT and Emax families. AC/DC Supply: Designed to operate on a 220 – 250 V AC/DC coil or control voltage. Accessory Module: Used as an add‑on to extend protective functionality of circuit breakers. Compact Design: Sized to integrate with breaker accessories in panel installations. DIN/Panel Friendly: Dimensions and mounting suit standard electrical enclosure layouts. Electrical Ratings Rated Control Supply Voltage: 220 – 250 V AC/DC — works with both AC and DC control supplies. Input Type: Designed for AC and DC voltage sensing used in timing logic. Timing Function: Electronic delay between voltage condition and release action (helps avoid unwanted trips). Integration: Works with other breaker control accessories to coordinate undervoltage and delayed release behavior. Mechanical & Environmental Module Width: Approximately 150 mm. Height: Approximately 60 mm. Depth: Approximately 200 mm. Weight: Around 0.25 kg. Installation: Connected as an accessory to compatible breakers; panel or accessory rail mounting typical. Ambient Conditions: Suitable for standard industrial panel environments. Functional Use This electronic time delay unit is used to delay breaker opening in response to certain voltage conditions, reducing the chance of unnecessary trips during short disturbances. For example, in motor control centers or distribution panels, it helps maintain continuity through transient dips, while still providing protective action if the condition persists. Typical Applications Low‑voltage power distribution panels where transient voltage drops are common. Motor control and feeder circuits requiring controlled undervoltage response. Industrial automation systems needing enhanced coordination between supply conditions and breaker operation. Enhancing protective functionality of ABB Tmax and Emax circuit breakers by adding timing logic.

Key Features Fuse Type: gG general‑purpose HRC fuse link — suitable for both overload and short‑circuit protection. Format: DIN‑type fuse link for use in standard fuse holders or switch‑fuse disconnect assemblies. High Breaking Capacity: Designed to safely interrupt high fault currents and protect connected equipment. Replaceable Link: The fuse element can be replaced after a fault trip, minimizing downtime. Compact Construction: Space‑efficient design for integration into modular switchgear and panels. Electrical Ratings Rated Current: 250 A — continuous current rating for protecting circuits. Rated Operational Voltage: 690 V AC — suitable for low‑voltage three‑phase systems. Utilization Category: gG — general purpose, covering conductor and equipment protection duties. Standards Compliance: Designed in accordance with international low‑voltage fuse standards for HRC links. Mechanical & Physical Fuse Size: NH1 / DIN size 1 — compact form factor suited to DIN‑rail fuse bases. Housing: Robust metallic/ceramic body engineered for reliable operation in power circuits. Terminal Style: Knife blade or blade contacts to fit compatible holders securely. Environmental Operating Conditions: Suitable for standard indoor electrical panels and distribution cabinets. Installation: Installed inside an appropriate fuse holder or disconnect switch mounting, providing safe isolation and fault interruption. Typical Applications Low‑voltage power distribution protection in industrial and commercial systems. Motor feeder and transformer protection against overloads and short circuits. Control panel and switchboard protection when paired with DIN‑type fuse holders. General circuit protection where HRC performance is required.

Key Features Switch Type: ON‑OFF isolator / manual control switch — used to manually connect or disconnect circuits. Pole Configuration: 2‑pole design for switching both poles of a circuit. Contacts: Two normally open (NO) contacts — closes when switched ON. Compact Module: Slim profile suitable for modular panel mounting (approx. half‑module width). DIN‑Rail Ready: Designed for installation on standard DIN rails inside electrical panels. Clear ON/OFF position indication on the actuator for visual status of the switch. Electrical Ratings Rated Current: 16 A continuous load capacity suitable for general control and power circuits. Rated Operational Voltage: Designed for use up to 250 V / 400 V AC in typical low‑voltage systems. Rated Frequency: Usable on both 50 Hz and 60 Hz AC systems. Switching Category: Suitable for switching mixed resistive and inductive loads with moderate overloads. Short‑Circuit Breaking Capacity: Capable of interrupting fault currents up to 3 kA in typical installations. Rated Impulse Withstand Voltage: Provides robust dielectric performance to withstand voltage transients. Mechanical & Environmental Poles: 2 for switching of both line conductors. Protection Rating: IP20 at terminals when mounted inside an enclosure. Operating Temperature Range: Suitable for typical electrical panel ambient conditions. Mounting: Snap‑on DIN rail or panel mounting as part of modular control assemblies. Physical & Installation Module Width: Approx. 9 mm (half‑module) for space‑efficient panel installation. Dimensions: Compact form factor to fit standard control panel layouts. Terminals: Screw‑type or clamp connections for secure conductor installation. Weight: Lightweight design for easy handling and integration. Typical Applications Manual control of auxiliary circuits such as indicators, lights, fans, or pumps. ON‑OFF control input in control panels and distribution boards. Switching of electrical loads in industrial machines and automation systems. Panel‑mounted isolator switch for maintenance and safety applications.

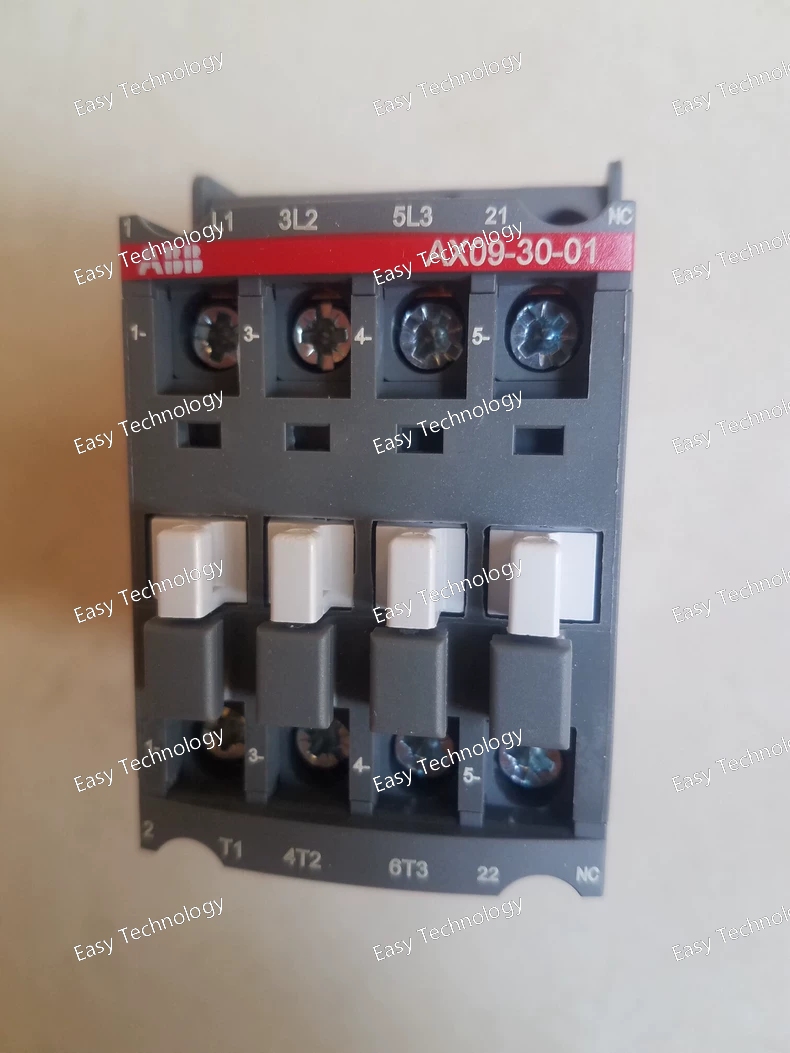

Parameters Main Circuit Ratings Rated Operational Voltage: Up to 690 V AC across the main power contacts. Rated Operational Current (AC‑1): Suitable for general switching (e.g., ~22 A at 690 V or ~22 A at 220–240 V). Rated Motor Duty (AC‑3): Typical duty current ~9 A for 220–440 V motors; lower at higher voltages. Rated Power (AC‑3): Several kilowatts depending on supply voltage (e.g., ~2–5.5 kW range). Rated Insulation Voltage: ~690 V. Rated Impulse Withstand Voltage: ~6 kV (control and main circuits). Control / Coil Coil Rating: 110 V AC control supply — optimized for use on 50 Hz or 60 Hz mains within the rated range. Contact Ratings Auxiliary Contact: One auxiliary changeover output useful for control feedback. Switching Categories: AC‑15: Control circuit switching at moderate currents (e.g., few amps). DC‑13: Lower DC load switching capability. Switching Performance Electrical Switching Frequency: Typical rates for control and power contacts (hundreds to over one thousand operations per hour under rated categories). Mechanical Switching Frequency: Higher mechanical life frequency for repeated operations. Mechanical & Environmental Poles: 3 main power poles plus auxiliary contacts. Operating Environment: Designed for standard industrial ambient conditions (wide temperature range typical for control equipment). Mounting: Compact enclosure suited for panel or component mounting in control cabinets. Physical Dimensions & Installation Footprint: Slim profile for dense panel layouts. Weight: Lightweight, facilitating easy mounting and replacement. Terminals: Screw terminals for both power and control wires. Typical Applications Motor starters and soft starters (as the main contactor). Control panels for pumps, fans, compressors, and conveyors. General power switching in automation and industrial installations. Integration with overload relays and control logic systems.

Parameters Nominal Fuse Current: 200 A — protects circuits with continuous current up to this value before blowing. Utilization Category: gG — general purpose protection for overload and short circuit in power distribution. Rated Operational Voltage: Up to 690 V AC for three‑phase networks or 500 V AC in some configurations. Breaking Capacity: High fault current interruption capability suited to industrial electrical installations. Standards: Designed to meet relevant international low‑voltage fuse standards for HRC protection. Mechanical & Physical Fuse Size: DIN‑type HRC link with compact rectangular profile for modular assemblies. Construction: Metal and ceramic/fuse element housing engineered for safe, high‑energy fault interruption. Replacement: Plug‑out/plug‑in style fuse link for easy maintenance and replacement within compatible holders. Environmental & Operational Operating Environment: Suitable for installation inside electrical enclosures, distribution boards, motor control centers, and switchgear. Ambient Conditions: Designed to operate over typical industrial ambient temperature ranges. Installation: Used with appropriate DIN‑type fuse holders or switch‑fuse disconnect devices for secure, code‑compliant installations. Typical Applications Primary overload and short‑circuit protection in low‑voltage power distribution networks. Protection of motors, transformers, and feeders in industrial control panels. Overcurrent protection in switchboards, motor control centers (MCC), and distribution panels. Integration with fusible disconnect switches to provide combined isolation and protection.

Parameters Main Circuit Rated Operational Current: 72 A (continuous). Rated Operational Voltage: 208 – 600 V AC three‑phase. Rated Power (Typical): Approx. 22 kW at 230 V Approx. 37 kW at 400 V Approx. 45 kW at 500 V Control Circuit Control Supply Voltage: 100 – 240 V AC (50/60 Hz). Rated Frequency: 50/60 Hz. Control Logic: Front‑panel potentiometers for adjusting start/stop ramp times. Outputs Auxiliary Relays: RUN — indicates the motor is running. TOR — indicates the end of the ramp (full speed reached). Relays typically provide normally open (NO) contact outputs for integration with external control or indicator circuits. Performance & Adjustments Start Ramp Time: Adjustable (typically 0 – 20 s) to control acceleration. Stop Ramp Time: Adjustable (typically 0 – 20 s) for controlled deceleration. Voltage Control: Enables smooth ramping of applied voltage to reduce torque shock. Mechanical & Environmental Mounting: Designed for control cabinet installation; compact footprint for efficient panel layout. Operating Temperature: Suitable for typical industrial ambient conditions. Protection Rating: Basic industrial protection; intended for installation inside an enclosed panel. Physical Dimensions Width: Approximately 180 mm Height: Approximately 220 mm Depth: Approximately 70 mm Weight: Around 2.1 kg Typical Applications Starting and stopping three‑phase induction motors such as pumps, fans, compressors, and conveyors. Applications where reduced mechanical wear and lower electrical peak currents are desired. Motor control systems in manufacturing, processing plants, and HVAC installations.