PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

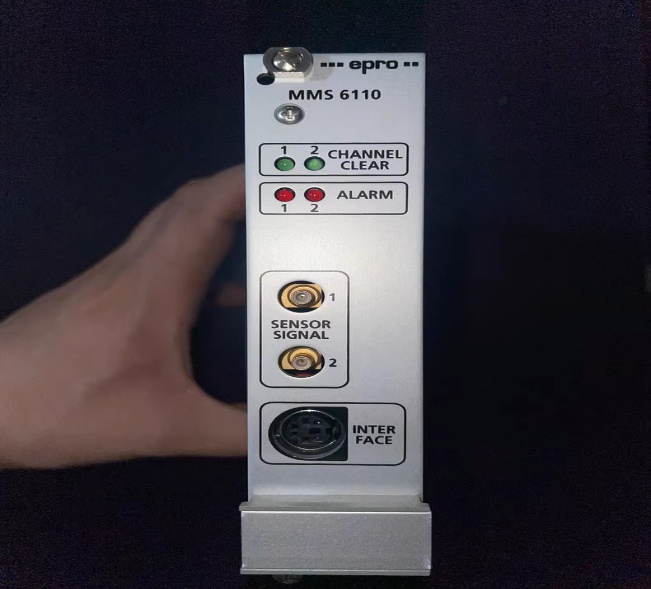

EPRO

Core Function: Advanced dual-channel monitoring system for critical machinery protection, measuring: ✓ Vibration (velocity/displacement) ✓ Shaft position (via proximity probes) ✓ Rotational speed Key Features: • Dual Input Channels – Supports eddy current, velocity, and tachometer signals • Measurement Ranges: Vibration: 0-500 µm Displacement: 0-2.0 mm Speed: 0-20,000 RPM • Protective Outputs: 2x 4-20mA analog signals 4x alarm relays (Danger/Warning) RS-485/Modbus + optional Ethernet Technical Specs: Power: 24V DC or 100-240V AC Operating Temp: -20°C to +70°C Compliance: API 670, ISO 10816 Typical Applications: Steam/gas turbine monitoring Compressor protection systems Critical pump vibration analysis Configuration: Intuitive setup via front panel or EPRO CMS 2000 software

579

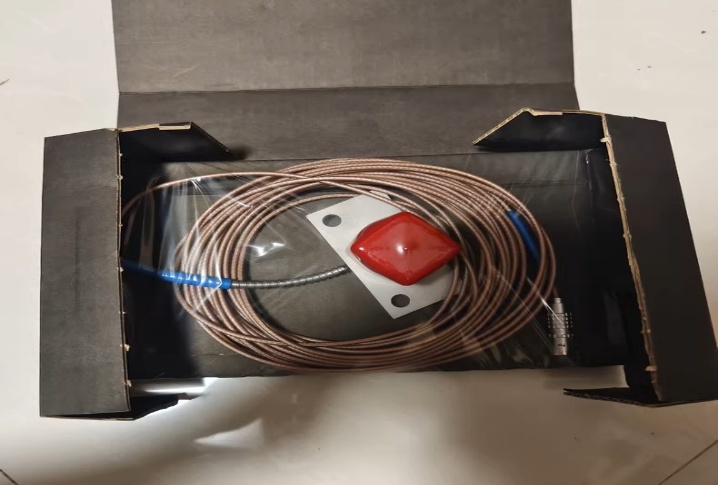

EPRO

Core Function: Compact 5mm eddy current sensor for precision vibration and displacement monitoring in tight spaces. Key Specifications: • Sensitivity: 8.0 mV/µm (standard calibration) • Measuring Range: 0-1.0mm (1000µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V linear analog signal Mechanical Details: ✓ 5mm diameter probe (smallest in PR6400 series) ✓ M8×1 threaded mounting ✓ Operating Temp: -30°C to +120°C ✓ Vibration resistant up to 20g Typical Applications: Small motor/compressor shaft monitoring Precision bearing clearance measurement Space-constrained machinery installations System Integration: • Compatible with EPRO MMS6000 monitors • Standard 5m/9m cable options • CON021 quick-disconnect available Compliance: Meets API 670 machinery protection standards

893

EPRO

Core Functionality: Single-channel vibration monitoring module designed for industrial machinery protection, specializing in velocity measurement for rotating equipment. Key Specifications: • Measurement Range: 0.5-20 mm/s RMS (velocity) • Frequency Bandwidth: 10Hz-1kHz (ISO 10816 compliant) • Accuracy: ±1% of full scale • Sampling Rate: 1kHz real-time processing I/O Configuration: ✓ 1x velocity sensor input (4-20mA/0-10V) ✓ 1x isolated 4-20mA output ✓ 2x programmable alarm relays (SPDT) ✓ RS-485 Modbus communication Physical Specifications: Power Supply: 24V DC (±10%) Operating Temp: -20°C to +70°C Enclosure: IP20 rated (panel mount) Compliance: CE, ISO 10816 Typical Applications: Motor and pump vibration monitoring Fan and blower protection systems General industrial equipment condition monitoring Configuration: Simple setup via front panel interface or EPRO CMS 2000 software

533

EPRO

Core Function: Dual-channel monitoring system for critical rotating equipment, measuring: ✓ Vibration (velocity/displacement) ✓ Shaft position (via proximity probes) ✓ Rotational speed Key Features: • Dual Input Channels – Supports eddy current probes, velocity sensors, and tachometers • Measurement Ranges: Vibration: 0-500 µm Displacement: 0-2.0 mm Speed: 0-20,000 RPM • Protective Outputs: 2x 4-20mA analog signals 4x alarm relays (Danger/Warning) RS-485 Modbus communication Technical Specs: Power: 24V DC or 100-240V AC Operating Temp: -20°C to +70°C Compliance: API 670, ISO 10816 Typical Applications: Steam/gas turbine monitoring Compressor protection systems Critical pump vibration analysis Configuration: Easy setup via front panel or EPRO CMS 2000 software

521

EPRO

Core Function: Single-channel vibration monitor for industrial machinery protection, measuring: ✓ Vibration velocity (RMS or peak) ✓ Displacement (optional) Key Features: • Input: Accepts velocity sensors (4-20mA/0-10V) & eddy current probes (with conditioner) • Measurement Range: Velocity: 0.5-20 mm/s RMS Displacement: 0-500 µm pk-pk • Dynamic Response: 10Hz-1kHz (ISO 10816 compliant) • Outputs: 1x 4-20mA analog 2x alarm relays (Danger/Warning) RS-485 Modbus interface Technical Specs: Power: 24V DC Operating Temp: -20°C to +70°C Enclosure: IP20 (panel mount) Typical Use Cases: Motor/pump vibration monitoring Fan/compressor bearing protection Standalone safety systems Compliance: CE, ISO 10816

904

EPRO

Core Function: High-range eddy current displacement sensor for industrial vibration and position monitoring. Key Specifications: • Sensitivity: 3.0 mV/µm (-030 suffix) • Extended Range: 0-3.0mm (3000µm) • Output: Linear -2 to -20V DC • Frequency Response: DC to 10kHz Mechanical Features: ✓ 8mm diameter probe ✓ M10×1 threaded mounting ✓ -30°C to +120°C operation ✓ 20g vibration resistant Typical Applications: Large turbine shaft monitoring Heavy compressor thrust measurement Industrial machinery protection System Integration: • Compatible with EPRO MMS6000 series • Standard 5m/9m cable options • CON021 quick-connect available Compliance: Meets API 670 machinery protection standards

741

EPRO

Compact Single-Channel Solution The EPRO A6500 CC is a space-saving monitoring module designed for critical machinery protection, measuring: ✓ Vibration (velocity/displacement) ✓ Shaft displacement (via eddy current probes) ✓ Rotational speed (RPM) Key Features • Input Flexibility - Accepts signals from: Eddy current probes (PR642x series) Velocity sensors (4-20mA/0-10V) Tachometer pulses • Measurement Ranges: Vibration: 0-500µm Displacement: 0-2.0mm Speed: 0-20,000 RPM • Outputs: 1x 4-20mA analog output 2x alarm relays (SPDT) RS-485 Modbus communication Technical Specifications • Power: 24V DC (±10%) • Operating Temp: -20°C to +70°C • Enclosure: IP20 panel-mount • Compliance: API 670, ISO 10816 Typical Applications Standalone pump/motor monitoring Compact machinery protection systems Retrofit installations with space constraints

234

EPRO

Core Function: High-sensitivity eddy current sensor for precision vibration and displacement monitoring in critical rotating equipment. Key Specifications: • Sensitivity: 14.0 mV/µm (-140 suffix) • Range: 0-1.4mm (1400µm) • Output: Linear -2 to -20V DC • Bandwidth: 0-10kHz Mechanical Features: ✓ 8mm probe diameter ✓ M10×1 threaded mounting ✓ -30°C to +120°C operation ✓ 20g vibration resistant Typical Deployments: Gas turbine shaft monitoring Compressor axial position Critical pump vibration analysis System Integration: • Direct compatibility with EPRO MMS6000 series • Standard 5m/9m cable options • CON021 quick-connect available Compliance: API 670 machinery protection standard

384

EPRO

Core Functionality: • Industrial eddy current displacement sensor • Non-contact vibration measurement solution • API 670 compliant for machinery protection Key Specifications: ▸ Sensitivity: 8.0 mV/µm (standard -010 calibration) ▸ Measuring Range: 0-1.0 mm (1000 µm) ▸ Frequency Response: DC to 10 kHz ▸ Output: -2 to -20V linear analog signal Mechanical Details: • 8mm diameter probe with M10×1 thread • Operating Temp: -30°C to +120°C (sensor head) • Vibration resistant up to 20g Typical Applications: ✓ Turbine shaft vibration monitoring ✓ Compressor axial displacement ✓ Rotating equipment protection systems System Integration: • Compatible with EPRO MMS6000 monitors • Standard 5m/9m cable options • CON021 quick-disconnect available

240

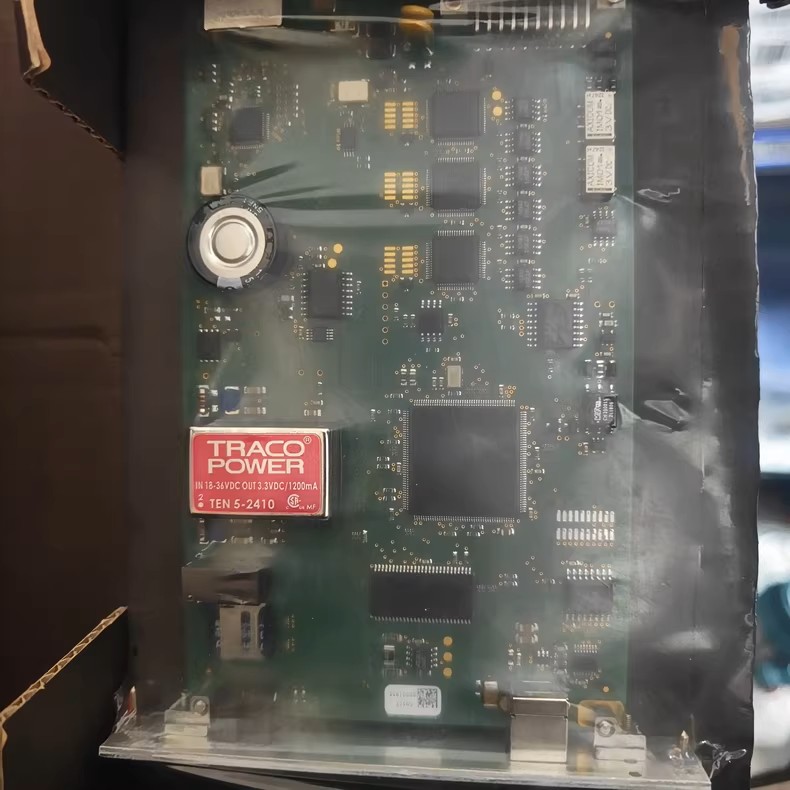

EPRO

Core Functionality: A 4-channel industrial monitoring system designed for comprehensive machinery protection, measuring: ✓ Vibration ✓ Displacement ✓ Speed ✓ Temperature (optional) Key Technical Specs: • Inputs: Accepts signals from eddy current probes, velocity sensors, tachometers, and RTD/TCs • Measurement Ranges: Vibration: 0-500 µm Displacement: 0-2.0 mm Speed: 0-20,000 RPM • Outputs: 4x 4-20mA + 8 alarm relays • Communications: RS-485 (Modbus) + Ethernet options Industrial Features: • Complies with API 670 standards • -20°C to +70°C operation • Panel-mounted IP20 enclosure Typical Deployment: Ideal for turbine/compressor monitoring in: Power generation Oil & gas Heavy industrial applications Configuration: Programmable via front panel or CMS 2000 software

701

EPRO

Key Features: ✔ Dual Monitoring Channels – Supports eddy current probes (e.g., PR6426) and velocity sensors ✔ Wide Measurement Range – Vibration (0–500 µm), Displacement (0–2.0 mm), Speed (0–20,000 RPM) ✔ Programmable Alarms – 4 relay outputs (Danger/Warning) with SPDT contacts ✔ Analog & Digital Outputs – 4–20 mA signals + RS-485/Modbus communication ✔ Robust Design – Operates in -20°C to +70°C, compliant with API 670 Typical Applications: Turbine/compressor protection systems Bearing condition monitoring Integration with DCS/PLC controls

362

EPRO

Key Features: Sensitivity: 7.87 mV/µm (factory-calibrated) Measurement Range: 0–1.3 mm (1300 µm) Output: -2 to -20V DC (linear analog signal) Frequency Response: 0–10 kHz (suitable for dynamic measurements) Robust Design: Operates in -30°C to +120°C environments Typical Applications: Shaft vibration monitoring (turbines, compressors) Axial displacement measurement Machinery protection systems (compatible with EPRO MMS6000) Compatibility: 8mm probe with CON021 connector options Meets API 670 standards for industrial reliability A trusted solution for accurate, real-time machinery health monitoring.

750