PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

EPRO

Core Function: High-temperature eddy current sensor designed for extreme environment displacement and vibration monitoring in critical rotating machinery. Key Specifications: • Sensitivity: 10.1 mV/µm (±5%) • Measurement Range: 0-1.0mm (1000µm) • Frequency Response: DC to 10kHz • Temperature Range: Sensor head: -40°C to +200°C (peak 250°C) Cable: -40°C to +105°C Robust Design Features: ✓ 8mm high-temperature probe ✓ M10×1 threaded mounting ✓ Mineral-insulated cable (5m standard) ✓ 20g vibration resistance ✓ 4MPa pressure rating Measurement Performance: Target material: AISI 4140 steel Linear range: 60% of full scale Accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 systems • High-temperature cable option • API 670 compliant Typical Applications: Gas turbine blade clearance monitoring Steam turbine shaft vibration (hot sections) Nuclear/power plant critical equipment

646

EPRO

Core Function: Industrial piezoelectric accelerometer for machinery vibration monitoring, designed for predictive maintenance and condition-based monitoring systems. Key Specifications: • Sensitivity: 10 mV/g (±5%) • Measurement Range: ±50 g peak • Frequency Response: 0.5Hz-5kHz (±10%) • Output Type: Voltage mode (requires 18-30V DC excitation) Robust Design: ✓ Stainless steel housing (IP67 protection) ✓ M6 threaded mounting ✓ -40°C to +120°C operation ✓ 500g shock resistance Measurement Performance: Resonant frequency: >25kHz Transverse sensitivity: <5% Broad frequency range for mechanical fault detection System Integration: • Compatible with EPRO MMS6000 monitoring systems • Standard 5m integral cable • Requires signal conditioner (e.g., CON051) for 4-20mA conversion Typical Applications: Motor and pump bearing monitoring Gearbox vibration analysis Compressor blade condition assessment Industrial fan monitoring Compliance: Meets ISO 10816 and API 670 standards Special Features: Hermetically sealed for harsh environments Low-noise output for precise measurement Wide temperature operation range

456

EPRO

Core Function: High-density 12-channel monitoring system for comprehensive machinery protection in large industrial installations. Key Specifications: • Channels: 12 fully configurable inputs • Measurement Capabilities: Vibration: 0-500 µm pk-pk Displacement: 0-2.0 mm Speed: 0-20,000 RPM • Sampling Rate: 1kHz per channel • Accuracy: ±1% FS System Architecture: ✓ 12x isolated 4-20mA outputs ✓ 24 programmable alarm relays (SPDT) ✓ Dual communication ports: RS-485 Modbus RTU Ethernet (standard) Optional Profibus-DP Physical Specifications: Power Supply: 100-240V AC or 24V DC Operating Temp: -20°C to +70°C Enclosure: IP20 rack-mount design Dimensions: Standard 19" rack width Advanced Features: Individual channel configuration Redundant power supply option CMS 2000 software compatible Real-time multi-channel LCD display Typical Applications: Power plant turbine supervisory systems Multi-unit compressor stations Large generator protection Plant-wide condition monitoring Compliance: Meets API 670 and ISO 10816 standards CE and UL certified Special Notes: "-N" suffix indicates standard industrial version Supports hot-swappable module replacement Ideal for centralized monitoring solutions

79

EPRO

Core Function: Industrial eddy current sensor for extended-range displacement monitoring in heavy rotating equipment Key Specifications: • Sensitivity: 3.1 mV/µm (±5%) • Extended Range: 0-3.1mm (3100µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC linear signal Mechanical Configuration: ✓ 8mm diameter probe ✓ M10×1 threaded mounting ✓ Operating temperature: -30°C to +120°C ✓ Vibration resistant to 20g Measurement Performance: Target material: AISI 4140 steel Linear operating range: 60% of full scale Typical accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 monitoring systems • Standard 5m/9m cable options • CON021 quick-disconnect available Special Features: Extended 3.1mm measurement range Special /005 variant with enhanced environmental tolerance Optimized for heavy industrial applications Typical Applications: Large turbine shaft monitoring Compressor thrust bearing measurement Heavy machinery protection systems Compliance: Meets API 670 machinery protection standards

136

EPRO

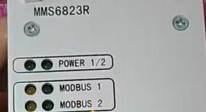

Core Function: Ruggedized dual-channel monitoring system designed for extreme industrial environments, measuring: ✓ Vibration (velocity/displacement) ✓ Shaft position ✓ Rotational speed Key Specifications: • Input Channels: 2 fully independent • Measurement Ranges: Vibration: 0-500 µm pk-pk Displacement: 0-2.0 mm Speed: 0-20,000 RPM • Sampling Rate: 1kHz per channel Ruggedized Design: ✓ IP66 rated enclosure ✓ -40°C to +85°C operation ✓ 5g vibration resistance (10-500Hz) ✓ ATEX/IECEx certified options Output & Communication: 2x isolated 4-20mA outputs 4x alarm relays (SPDT) RS-485 Modbus + Ethernet option Typical Applications: Offshore oil & gas platforms Mining and heavy machinery Mobile equipment monitoring Hazardous area installations Configuration: Intuitive LCD interface or CMS 2000 software Compliance: API 670, ISO 10816 standards Special Features: Dual-channel redundancy Extended temperature operation Corrosion-resistant housing

181

EPRO

Core Function: Industrial eddy current sensor for wide-range displacement monitoring in heavy rotating equipment Key Specifications: • Sensitivity: 3.0 mV/µm (±5%) • Extended Range: 0-3.0mm (3000µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC linear signal Mechanical Configuration: ✓ 8mm diameter probe ✓ M10×1 threaded mounting ✓ Operating temperature: -30°C to +120°C ✓ Vibration resistant to 20g Measurement Performance: Target material: AISI 4140 steel Linear operating range: 60% of full scale Typical accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 monitoring systems • Standard 5m/9m cable options • CON021 quick-disconnect available Typical Applications: Large turbine shaft monitoring Compressor thrust bearing measurement Heavy industrial machinery protection Special Features: Optimized for wide displacement range applications Special variant (/002) with enhanced environmental tolerance Compliance: Meets API 670 machinery protection standards

897

EPRO

Core Function: Industrial eddy current sensor for vibration and displacement monitoring in rotating machinery Key Specifications: • Sensitivity: 4.0 mV/µm (±5%) • Measurement Range: 0-2.0mm (2000µm) • Frequency Response: DC to 10kHz • Output Signal: -2 to -20V DC (linear) Mechanical Design: ✓ 8mm diameter probe ✓ M10×1 threaded mounting ✓ Operating temperature: -30°C to +120°C ✓ Vibration resistant to 20g Measurement Performance: Target material: AISI 4140 steel Linear operating range: 60% of full scale Typical accuracy: ±1% of full scale System Integration: • Compatible with EPRO MMS6000 monitoring systems • Standard 5m/9m cable options • CON021 quick-disconnect available Typical Applications: Turbine shaft vibration monitoring Compressor axial position measurement Rotating equipment protection systems Compliance: Meets API 670 machinery protection standards Special Feature: Optimized for medium-range displacement measurements with stable output in harsh environments

892

EPRO

Core Function: Industrial eddy current sensor designed for wide-range displacement and vibration monitoring in heavy rotating equipment. Key Specifications: • Sensitivity: 2.1 mV/µm (±5%) • Extended Range: 0-2.1mm (2100µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC linear signal Mechanical Configuration: ✓ 8mm diameter probe ✓ M10×1 threaded mounting ✓ Operating temperature: -30°C to +120°C ✓ Vibration resistant to 20g Measurement Performance: Target material: AISI 4140 steel Linear operating range: 60% of full scale Typical accuracy: ±1% FS System Integration: • Compatible with EPRO MMS6000 monitoring systems • Standard 5m/9m cable options • CON021 quick-disconnect available Typical Applications: Large turbine shaft monitoring Compressor thrust bearing measurement Heavy industrial machinery protection Special Features: Optimized for wide displacement range applications Maintains stability in high-vibration environments Compliance: Meets API 670 machinery protection standards

704

EPRO

Core Function: High-sensitivity eddy current displacement sensor for precision machinery monitoring Key Specifications: • Sensitivity: 12.0 mV/µm (±5%) • Measurement Range: 0-1.2mm (1200µm) • Frequency Response: DC to 10kHz • Output: -2 to -20V DC (linear analog) Mechanical Configuration: ✓ 8mm diameter probe ✓ M10×1 threaded mounting ✓ Operating temperature: -30°C to +120°C ✓ Vibration resistance: 20g (50Hz) Measurement Performance: Target material: AISI 4140 steel Linear range: 60% of full scale Accuracy: ±1% of full scale System Integration: • Compatible with EPRO MMS6000 monitors • Standard 5m/9m cable options • CON021 quick-disconnect available Typical Applications: Turbine shaft vibration monitoring Compressor thrust position measurement Precision bearing clearance monitoring Compliance: API 670 machinery protection standard Special Feature: Enhanced 12.0 mV/µm sensitivity provides superior resolution for detecting minute displacement changes in critical equipment.

455

EPRO

Key Specs: Type: 3-axis IEPE accelerometer Sensitivity: 100mV/g (X/Y), 50mV/g (Z) Frequency Range: 0.5Hz-8kHz Measurement Range: ±50g (X/Y), ±100g (Z) Rugged Design: Titanium alloy housing M5 military-grade mounting IP68 submersible rating 10,000g shock survival Performance: <3% cross-axis sensitivity -55°C to +150°C operation MIL-DTL-38999 connector Applications: Aerospace structural testing Military/defense systems Harsh industrial environments

823

EPRO

Core Function: Industrial vibration sensor for machinery condition monitoring, measuring: ✓ Acceleration (±50g range) ✓ Velocity (via signal integration) Key Specifications: • Sensitivity: 10 mV/g (±5%) • Frequency Range: 0.5Hz-5kHz • Output: Voltage mode (requires 18-30V DC excitation) • Accuracy: ±1% typical Robust Design: ✓ Stainless steel housing ✓ IP67 protection rating ✓ M6 threaded mounting ✓ -40°C to +120°C operation Measurement Performance: Linear range: ±50g peak Resonant frequency: >25kHz Transverse sensitivity: <5% Typical Applications: Motor/pump bearing monitoring Compressor vibration analysis Gearbox condition assessment System Integration: • Compatible with EPRO MMS6000 systems • Standard 5m integral cable • Requires signal conditioner (e.g., CON051) Compliance: Meets ISO 10816 and API 670 standards

357

EPRO

Core Function: Industrial-grade eddy current sensor for extended-range displacement monitoring in heavy machinery applications. Key Specifications: • Sensitivity: 3.0 mV/µm • Wide Measurement Range: 0-3.0mm (3000µm) • Output Signal: -2 to -20V DC linear output • Frequency Response: DC to 10kHz Robust Design Features: ✓ 8mm diameter probe with M10×1 threading ✓ Extended temperature operation (-30°C to +120°C) ✓ Vibration resistant up to 20g ✓ Ruggedized cable/connector options (/10R variant) Measurement Performance: Target Material: Mild steel (AISI 4140) Linear Range: Middle 60% of full scale Accuracy: ±1% of full scale Typical Applications: Large turbine shaft vibration monitoring Compressor thrust position measurement Heavy industrial machinery protection System Integration: • Compatible with EPRO MMS6000 monitoring systems • Standard 5m/9m cable lengths available • CON021 quick-disconnect option Compliance: Meets API 670 machinery protection standards

886