PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

Parameter Category Specification Product Family / Type Numerical Feeder Protection Relay Standard Compliance IEC 60255, IEC 61850 (with communication module), ANSI/IEEE C37.90 Rated Auxiliary Supply Voltage (Us) 48 - 250 V DC / 48 - 240 V AC, 50/60 Hz (Auto-ranging) Current Input (CT Secondary) 1 A or 5 A (Hardware selectable) Voltage Input (VT Secondary) 100 / 110 / 120 / 200 / 220 / 230 / 240 / 380 / 400 / 415 / 480 V AC (Phase-to-Phase) Protection Functions • Phase Overcurrent Two stages: Instantaneous (I>) & Time-delayed (I>>) with multiple IDMT/DT curves. • Earth-Fault Current Directional or Non-directional. One stage (I0>>) with IDMT/DT curves. Highly sensitive setting range. • Voltage Protection Two stages each for Undervoltage (U<) & Overvoltage (U>). Definite time delay. • Thermal Overload (49) Single time constant model, alarm and trip stages. Setting Ranges (Typical) • Phase Current 0.1 - 15.0 x In (In steps) • Earth Current 0.01 - 3.00 x In (In steps) • Voltage 10 - 130% of Un (Un = Rated VT input) Measured Values (Display) IL1, IL2, IL3, I0 (earth), UL1, UL2, UL3, Uavg, Freq, P, Q, S, PF, etc. Output Contacts • Trip Relays 3 Changeover (CO) contacts, high-breaking capacity. • Signal Relays 3 Changeover (CO) contacts for alarms/signaling. • Binary Inputs 4 or 5 programmable, for external control/blocking. Communication (Optional) Plug-in modules for: IEC 61850, Modbus RTU (RS485), Profibus DP, IEC 60870-5-103. Human-Machine Interface (HMI) Backlit graphical LCD, 6 navigation keys, 6 LED indicators (Ready, Trip, Alarm, etc.). Event Logging Stores time-tagged fault records, alarms, and operations. Operating Temperature -25°C to +70°C (-13°F to +158°F) Housing & Mounting Compact, modular plastic case. Suitable for flush mounting on panel door or DIN rail. Dimensions (W x H x D) Approximately 105mm x 145mm x 122mm (specific to case style).

Technical Parameters: Parameter Category Specification Standard Compliance IEC 60255, IEC 60870-5-103 (with comm. module) Rated Auxiliary Voltage (Us) 48 - 250 V DC / 48 - 240 V AC (wide range) Rated Frequency (fn) 50 / 60 Hz Current Input (CT Secondary) 1 A or 5 A (selectable) Overcurrent Protection • Phase Stages 2 stages: Instantaneous (I>) & Time-delayed (I>>) • Earth-Fault Stage 1 stage: Time-delayed (I0>>) • Setting Ranges Phase: Typically 0.1 - 1.2 x In (I>) & 1 - 15 x In (I>>) in steps. Earth: Typically 0.02 - 1.2 x In (sensitive). (Refer to official manual for exact ranges.) • Time Curves Definite Time (DT), Inverse Definite Minimum Time (IDMT) per IEC 60255 (e.g., EI, VI, LTI). Output Contacts • Trip Relay 2 or 3 changeover (CO) contacts, rated for high making/breaking capacity. • Signal Relay 2 or more changeover (CO) contacts for alarms/signaling. Communication (Optional) RS485 port with protocol options: ABB SPA, Modbus RTU, or IEC 60870-5-103. Operating Temperature -25°C to +55°C (-13°F to +131°F) Mounting Plug-in or fixed mounting for panel or DIN rail installation. Case Dimensions Compact form factor (approx. 144mm x 144mm or similar, model-dependent).

Key Specifications Parameter Category Specification Drive Series/Model ACS310-03E-48A4-4 Rated Output Current 48.4 A Rated Output Power 22 kW (30 HP) Input Supply Voltage 380 - 480 V AC (± 10%), 3-phase Input Supply Phases 3-phase Output Voltage 0 - Input voltage Output Phases 3-phase Enclosure Rating IP20 / UL Open Type (Chassis). Requires installation in a protective cabinet. Cooling Method Fan-cooled Control Methods • Scalar Control (V/f) • ABB Direct Torque Control (DTC) for superior dynamic performance. Key Standard Features • Intelligent Pump and Fan Control (IPF): Includes auto-tuning for energy optimization, multi-pump control logic, dry pump protection, and anti-jam functions. • Embedded Application Programming: Built-in function blocks (timers, logic gates, comparators) for creating custom control logic without an external PLC. • Adaptive Program (AUP): Guides user through commissioning based on selected application. • Built-in Communication Protocols: Modbus RTU (RS-485) and BACnet MS/TP are standard for building automation integration. • LCD Keypad: Clear display with multi-language support and parameter copy function. • Integrated EMC Filter (Class A). • PID Controller: Advanced controller with sleep/wake, cascade control, and PID freeze functions. Protection Features • Motor thermal overload protection (I²t) • Pump/Fan-specific protection (dry pump, overload, underload) • Short circuit, ground fault, overcurrent, overvoltage protection • IGBT overtemperature protection • Automatic fault reset and restart Application Focus Large HVAC systems (fans, pumps), pressure boosting, water supply, cooling towers, and industrial fluid handling applications.

Key Specifications Parameter Category Specification Drive Series/Model DCS800-S02-0350-05 Motor Type DC Motor (Separate Armature & Field Supply) Rated Armature Current 350 A (Continuous DC Output) Rated Power Output ~160 kW (215 HP) (Estimated for a typical 460V DC motor armature). Power is voltage-dependent. Configuration Single Quadrant (S02): Forward motoring operation only. Cannot accept regenerative energy. Power Input 3-phase, 400V AC (±10%), 50/60 Hz (typical for "-05" code). Armature Output Voltage Variable DC, typically up to ~500V DC (for 400V AC supply). Field Supply Output Included. Adjustable DC output for motor field excitation. Control Method Digital thyristor (SCR) converter control. Programmable via DriveWindow™ software or control panel. Key Features • Digital Control Unit (DCU) for advanced programming. • Precise Speed Regulation (tachometer or EMF feedback). • Torque Control capability. • Extensive configurable I/O. • Field Weakening for extended speed range. • Comprehensive diagnostics and monitoring. Protection Features • Armature & field overcurrent. • Motor thermal overload (I²t). • Mains phase loss & undervoltage. • Overvoltage & overspeed. • Heatsink overtemperature. Typical Applications Large extruders, winders/unwinders (without regeneration), heavy mixers, machine tools, and large fans/pumps using DC motors.

Key Specifications Parameter Category Specification Drive Series/Base Model ACS580-01-044A-4 Rated Output Current 44 A Rated Output Power 22 kW (30 HP) Input Supply Voltage 380 - 480 V AC (± 10%), 3-phase Output Voltage/Phases 3-phase, 0 - Input voltage Enclosure Rating IP21 / UL Type 1 Cooling Method Fan-cooled Control Method ABB Direct Torque Control (DTC) Key Standard Features • Energy Optimizer: Automatically minimizes energy losses. • Intelligent Control Panel (IOP): Multilingual graphical display. • Embedded Application Macros: For pumps, fans, etc. • Built-in Modbus RTU (RS-485). • Built-in EMC Filter (Class A). Option +K454 Integrated Safe Torque Off (STO) Safety Function • Function: Prevents unexpected motor start-up by safely disabling the inverter's power output. • Safety Level: SIL 3 according to IEC 61800-5-2 / PL e according to ISO 13849-1. • Implementation: Two independent, safety-certified input channels for connection to safety devices (e.g., safety relays, PLCs, emergency stops). Protection Features • Comprehensive motor thermal and electrical protection. • Integrated functional safety via +K454. Application Focus Conveyors, mixers, pumps, fans, and general machinery where integrated personnel safety is required for maintenance or access.

Key Specifications Parameter Category Specification Drive Series/Base Model ACH550-BCR-012A-4 (Bypass Controller Ready) Rated Output Current 12 A Rated Output Power 5.5 kW (7.5 HP) Input/Output Voltage 380 - 480 V AC, 3-phase Enclosure Rating Designed for mounting within a bypass starter panel (specific enclosure depends on the panel builder). Control Method ABB Sensorless Flux Control (MFC) for HVAC. Key BCR Features • Dedicated logic and terminals for interfacing with external bypass contactors. • Automatic/manual transfer control between drive and bypass modes. • Motor current monitoring in bypass mode (optional). Option +C558 Embedded EtherNet/IP Adapter • Protocol: EtherNet/IP™ (Scanner/Adapter). • Ports: 2 x RJ45. • Function: Enables direct network integration for control and monitoring from a BMS or PLC (e.g., Allen-Bradley). Option +N2006 Extended I/O Kit • Function: Expands the drive's native I/O capacity to handle the complex switching logic and status monitoring of a bypass system. Option +X1558R Relay Output Expansion Kit • Function: Adds crucial Form C (changeover) relay outputs necessary to physically command the bypass contactors and provide isolated status signals (e.g., "Drive Running," "Bypass Active," "Fault"). Protection Features • Standard drive and motor protection. • Bypass system interlocks to prevent shorts. Application Focus Critical HVAC Systems with Bypass Requirements: Chilled Water Pumps, Condenser Pumps, Cooling Tower Fans, Critical Air Handling Units.

Key Specifications Parameter Category Specification Drive Series/Base Model ACS800-01-0070-5 Rated Output Current 70 A Rated Output Power 45 kW (60 HP) Input Supply Voltage 380 - 500 V AC (-15% / +10%), 3-phase Output Voltage/Phases 3-phase, 0 - Input voltage Enclosure Rating IP21 / UL Type 1 Cooling Method Fan-cooled Control Platform ABB Direct Torque Control (DTC), enabled by +P901. Option +K458 Enhanced Safety Functions Package • Typical Functions: Safe Stop 1 (SS1), Safely Limited Speed (SLS), Safe Brake Control (SBC), in addition to Safe Torque Off (STO). • Safety Level: SIL 3 according to IEC 61800-5-2 / PL e according to ISO 13849-1. • Purpose: Provides certified, integrated safety functions for protecting personnel and preventing hazardous machine motion. Option +P901 Standard Control Program with I/O Extension • Function: Provides essential firmware and I/O hardware. • Includes: Control logic, PID, extensive digital/analog I/O, and relay outputs. Protection Features • Comprehensive motor and drive electrical/thermal protection. • Integrated advanced safety functions via +K458. Application Focus Safety-critical applications: Cranes & Hoists, Robotics, Automated Material Handling, Presses, and machines with hazardous moving parts.

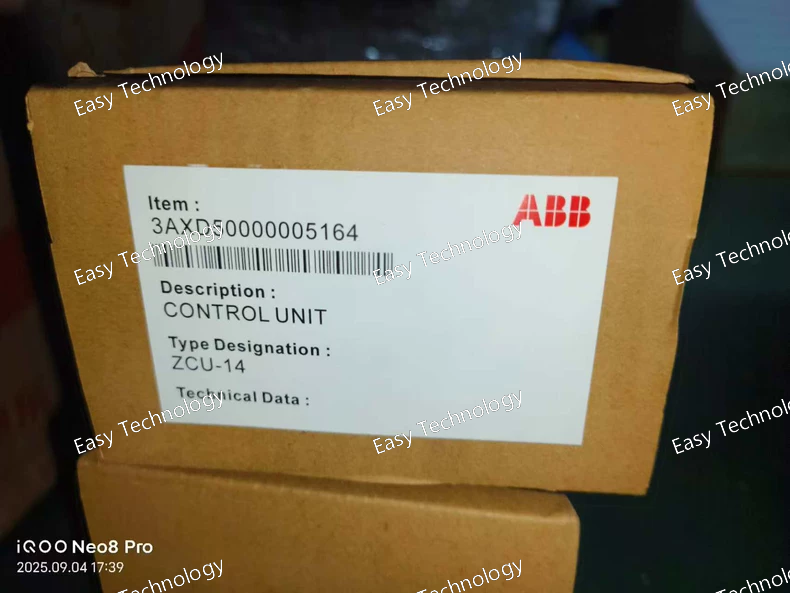

Key Specifications Parameter Category Specification Product Type Zone Control Unit (Safety & Cabinet Control Module) ABB Model ZCU-14 Order Code 3AXD50000005164 Primary Application ACS880 multidrive and other large ABB cabinet drive systems. Key Functions • Safety Interface: Processes safety inputs (e.g., emergency stop, safety door monitors) and controls safety outputs. • Cabinet Cooling Control: Controls and monitors cabinet ventilation fans, including fault detection. • Auxiliary Power Supervision: Monitors voltages of auxiliary power supplies within the zone. • Interlocking Logic: Provides programmable logic for interlocking between drives and external processes. • Diagnostics & Communication: Features LED status indicators and communication interfaces (typically via the drive's main control system). Typical Inputs/Outputs • Digital Inputs: For safety devices, temperature sensors, fan status. • Digital/Relay Outputs: For controlling contactors, fans, and status signals. • Communication: Integrates with the drive system's higher-level controller (e.g., via fiber optic or bus system). Mounting Designed for mounting inside an ACS880 or similar multidrive cabinet. Safety Role A key component in implementing the drive system's overall safety functions (e.g., Safe Torque Off - STO coordination, cabinet access safety).

Key Specifications Parameter Category Specification / Description Product Type Internal Component / Spare Part / Module Assembly ABB Order Code 3ABD00035957-D Associated Systems Likely part of a specific ABB industrial drive platform (e.g., ACS800, ACQ580, or related cabinet systems). Possible Functions Could be one of several specialized parts: • Control or Logic Board: A processing or signal conditioning board. • Power Supply Module: An auxiliary or gate driver power unit. • Communication Interface Board: For specific fieldbus protocols. • Fan Assembly / Cooling Unit: A replacement fan tray. • Capacitor Module: Part of the DC bus or snubber circuit. • I/O or Terminal Board: An extension or replacement I/O module. Physical Form Varies based on function (PCB assembly, mechanical unit with fans, capacitor block, etc.). Critical Note This is a highly specific spare part. Its exact function, compatibility, and technical specifications are defined solely by the host drive system it is designed for.

Key Specifications Parameter Category Specification Drive Series/Model ACS580-01-027A-4 Rated Output Current 27 A Rated Output Power 15 kW (20 HP) Input Supply Voltage 380 - 480 V AC (± 10%), 3-phase Input Supply Phases 3-phase Output Voltage 0 - Input voltage Output Phases 3-phase Enclosure Rating IP21 / UL Type 1 (Standard for -01) Cooling Method Fan-cooled Control Method ABB Direct Torque Control (DTC) Key Standard Features • Energy Optimizer: Automatically minimizes motor and drive losses for maximum energy efficiency. • Intelligent Control Panel (IOP): Plain language, multilingual graphical display for easy setup and monitoring. • Embedded Application Macros: Pre-programmed for common tasks (Pump/Fan, Hand/Auto, etc.). • Built-in EMC Filter (Class A). • Extensive Connectivity: Built-in Modbus RTU (RS-485); optional adapters for PROFINET, EtherNet/IP, PROFIBUS DP, etc. • Advanced PID Controller with sleep/wake and cascade control. • Flying Start and pump-specific functions (dry pump protection, anti-jam). Protection Features • Comprehensive motor thermal protection (I²t, PTC/KTY sensor inputs) • Full electrical protection (short circuit, ground fault, over/undervoltage, overcurrent) • IGBT and heatsink overtemperature protection • Motor stall and underload protection • Coated circuit boards available as an option for harsh environments. Application Focus Pumps, fans, compressors, conveyors, mixers, and other general-purpose industrial applications.

Key Specifications Parameter Category Specification Drive Series/Model ACH580-01-062A-4 Rated Output Current 62 A Rated Output Power 30 kW (40 HP) Input Supply Voltage 380 - 480 V AC (± 10%), 3-phase Input Supply Phases 3-phase Output Voltage 0 - Input voltage Output Phases 3-phase Enclosure Rating IP21 / UL Type 1 (Standard for -01) Cooling Method Fan-cooled Control Method ABB Direct Torque Control (DTC) Key Standard Features • Built-in Connectivity: BACnet MS/TP, Modbus RTU, and Metasys® N2 as standard. • Energy Optimizer: Automatically minimizes motor and drive losses. • Intelligent Control Panel: User-friendly display with application macros. • Built-in EMC Filter (Class A). • Advanced PID Controller with sleep/wake and anti-jam functions. • HVAC-specific functions: Fireman’s override, pump/fan curves. Protection Features • Comprehensive motor thermal protection (I²t, PTC sensor inputs) • Full electrical protection (short circuit, ground fault, over/undervoltage, overcurrent) • IGBT and heatsink overtemperature protection • Motor stall and underload protection • Conformal coated PCB option for harsh environments. Application Focus HVAC systems (air handling units, pumps, fans), light industrial applications, and building automation.

Key Specifications Parameter Category Specification Drive Series/Base Model ACS355-03E-15A6-4 Rated Output Current 15.6 A Rated Output Power 7.5 kW (10 HP) Input Supply Voltage 380 - 480 V AC (± 10%), 3-phase Output Voltage/Phases 3-phase, 0 - Input voltage Enclosure Rating IP20 / UL Open Type (Chassis). Requires installation in a protective cabinet. Control Panel Removable Control Panel (RCP) with backlit LCD. Cooling Method Self-cooled (with internal fan) Control Methods • Scalar Control (V/f) • ABB Direct Torque Control (DTC) Key Standard Features • Removable Control Panel (RCP). • Built-in EMC Filter (Class A). • Application Macros (Factory, Hand/Auto, Pump/Fan). • Built-in PID Controller. • Built-in Modbus RTU (RS-485). Option +B063 Embedded PROFIBUS DP-V1 Adapter Module • Protocol: PROFIBUS DP-V1 (符合 IEC 61158/EN 50170). • Interface: 9-pin D-sub female connector. • Function: Enables integration as a slave device in a PROFIBUS DP network. Supports Process Data Objects (PPO) for fast control and Parameter Channel (PKW) for parameter access. Supports data rates up to 12 Mbps with auto-baud detection. Protection Features • Motor thermal overload protection (I²t) • Short circuit, ground fault, overcurrent, overvoltage protection • IGBT overtemperature protection Application Focus General industrial machinery (Pumps, Fans, Conveyors) within PROFIBUS DP networked automation systems, commonly found with Siemens PLCs.